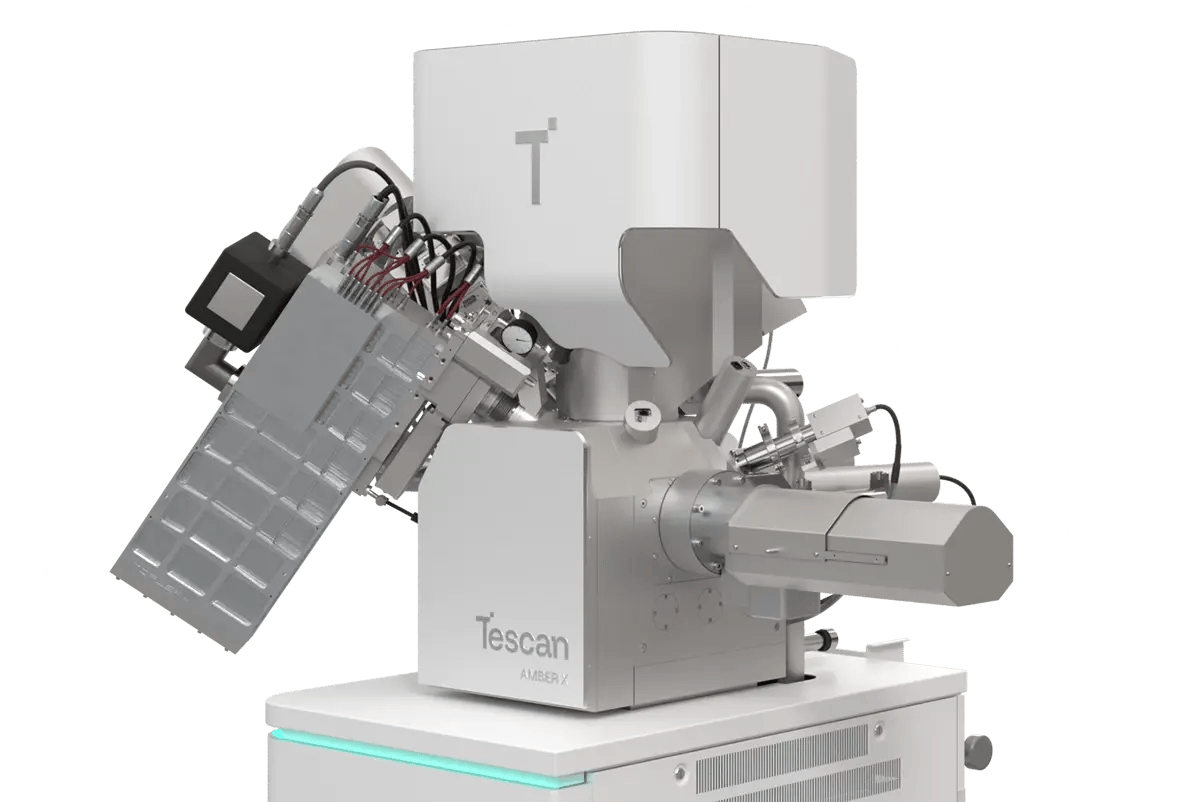

Understanding electrode porosity is key to predicting electrolyte uptake and cycle stability. Large-volume FIB-SEM tomography with Tescan AMBER X 2 delivers statistically meaningful 3D datasets that go beyond conventional 2D cross sections.

- Analyze void fraction and pore networks in 3D

- Quantify structural variation across large electrode volumes

- Correlate porosity with performance, lifespan, and manufacturing quality

.webp?width=794&height=587&name=1_Cross-sectional%20porosity%20characterization%20of%20the%20NMC%20cathode%20(1).webp)

.webp?width=600&height=400&name=Nov%C3%BD%20projekt%20(4).webp)

.webp?width=600&height=400&name=Nov%C3%BD%20projekt%20(3).webp)

.webp?width=600&height=400&name=Nov%C3%BD%20projekt%20(2).webp)