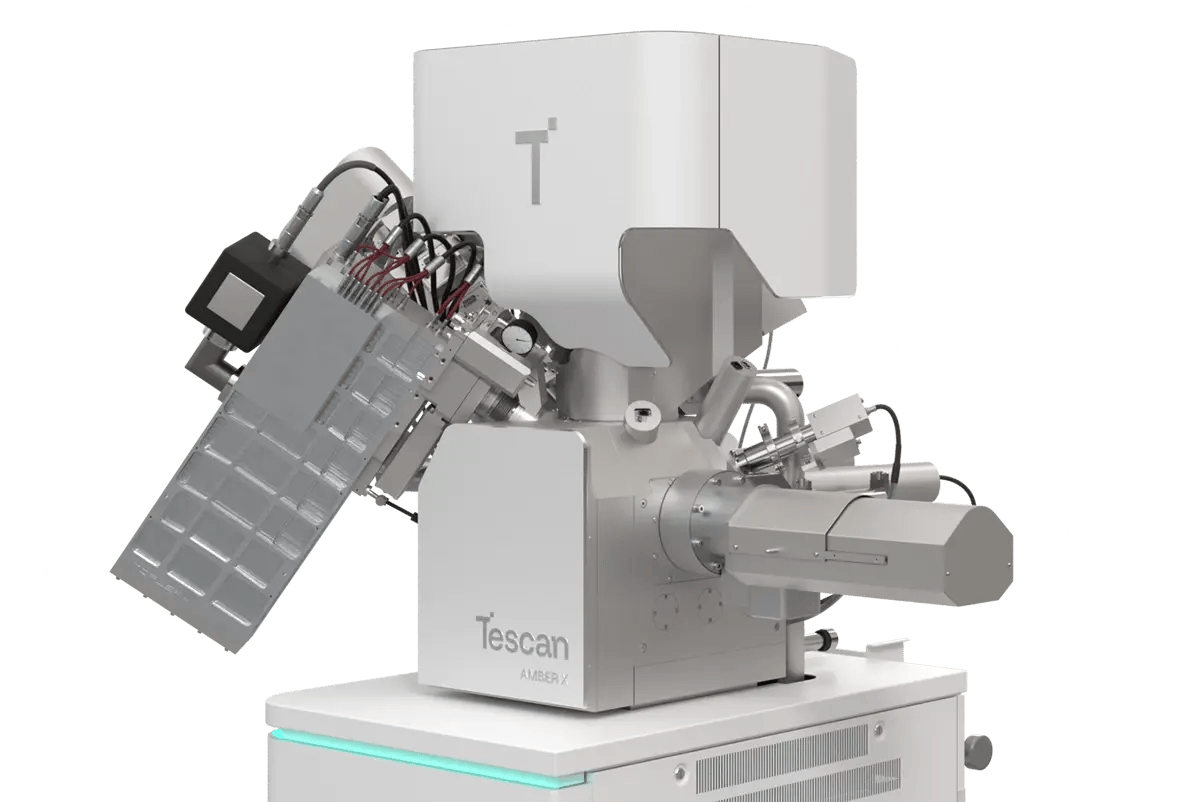

Tescan AMBER X 2

Tescan AMBER X 2 gives you access to high-throughput Xe plasma FIB milling and high-resolution SEM imaging. This allows you to reconstruct large volumes of electrode material in 3D with fine detail.

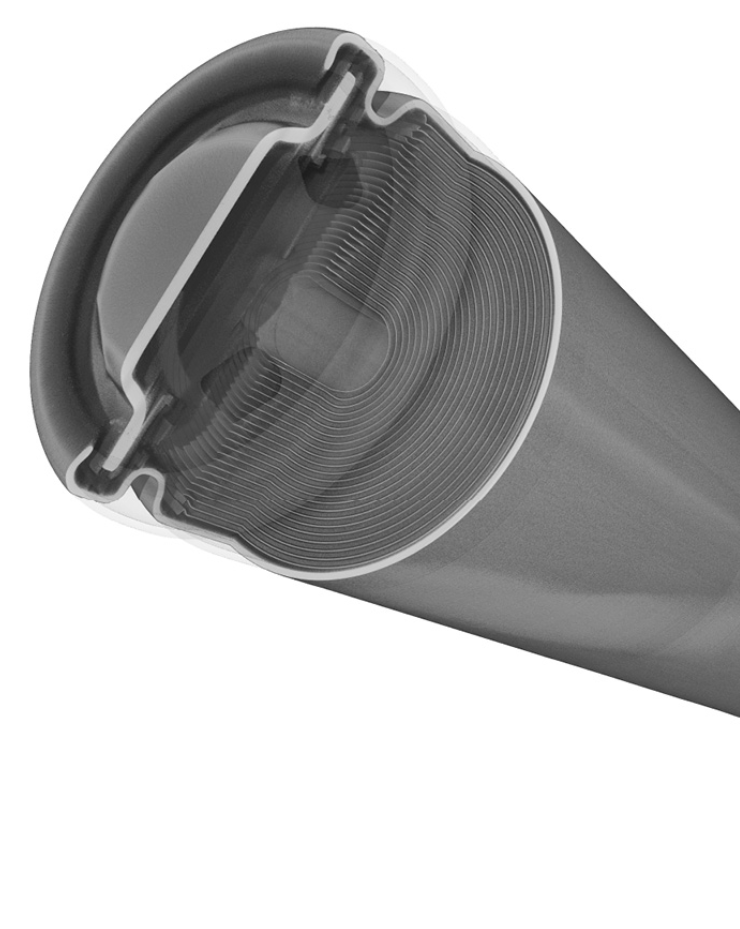

With this workflow, you can visualize pore morphology, porosity, and particle connectivity across entire electrode regions, helping you connect internal structure to performance, quality, and manufacturing outcomes.

- High-throughput Xe plasma FIB milling: Enables slicing of volumes up to hundreds of micrometers along all three spatial axes for statistically relevant analysis.

- High-resolution SEM imaging: Lets you capture nanoscale detail for accurate porosity and structural evaluation.

- Integrated 3D reconstruction: Enables you to generate complete volumetric datasets from slice-and-view data.

- Multimodal analytical capability: Allows access to multiple complementary analytical techniques, supporting detailed structural and chemical analysis across 3D volumes.