Tescan UniTOM XL

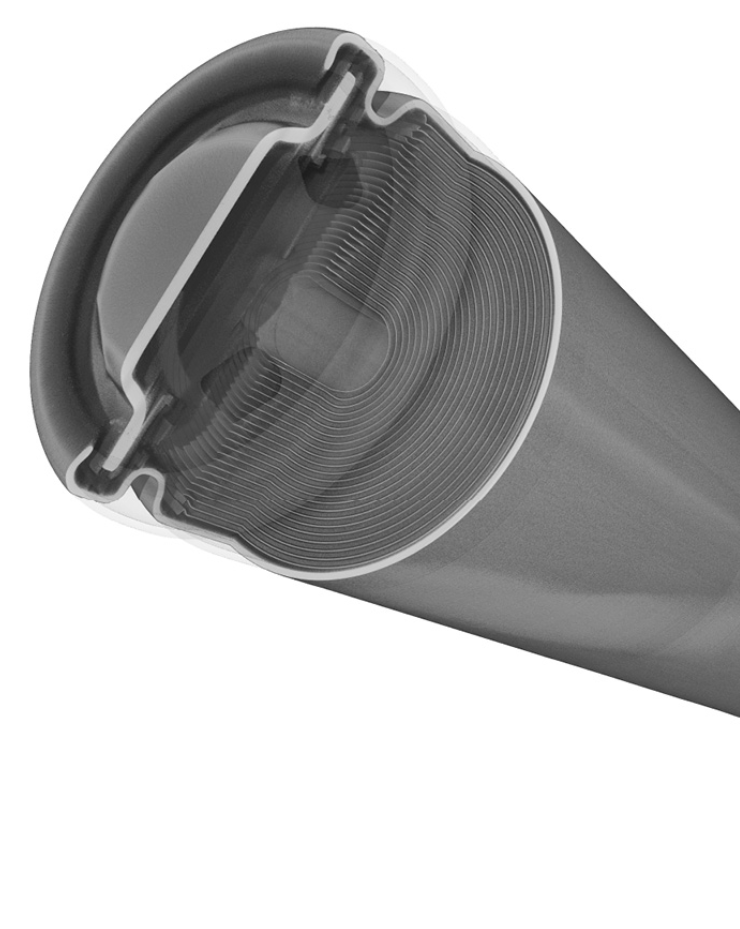

Tescan UniTOM XL enables full-volume, high-resolution scans of lithium-ion batteries — ideal for structural inspection, defect localization, and dimensional validation.

- Supports large samples, from cylindrical to pouch and prismatic cells

- High-resolution imaging with voxel sizes down to the single-micron range

- Compatible with VGSTUDIO MAX and Panthera™ for advanced segmentation