Tescan UniTOM XL

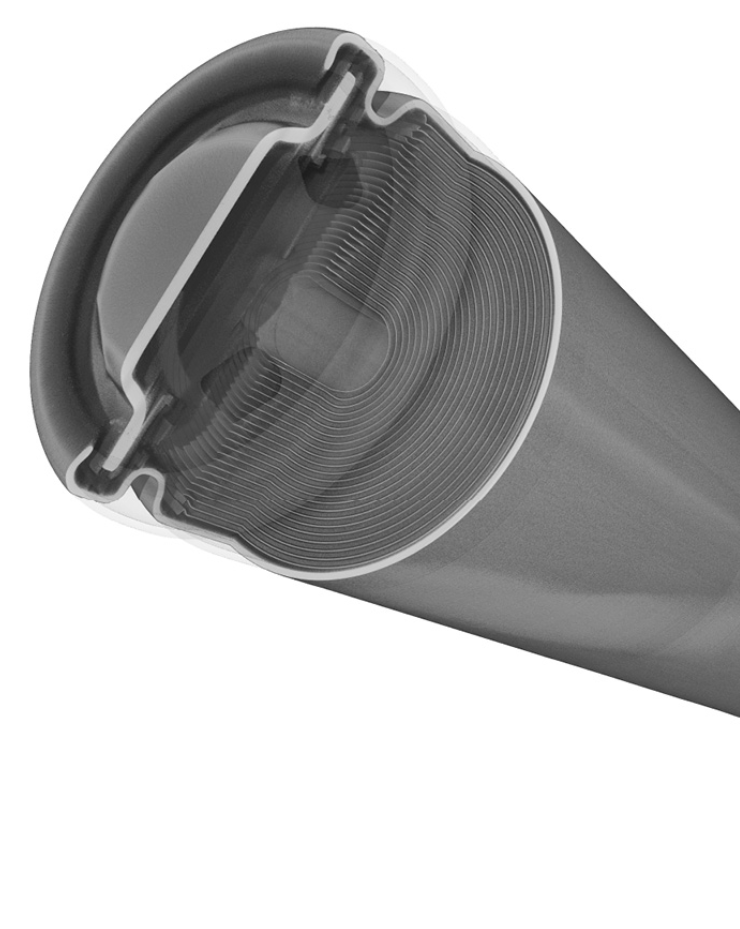

Tescan UniTOM XL combines speed, resolution, and large sample volume capacity, enabling complete, non-invasive imaging of cylindrical, prismatic, and pouch cells.

- Supports high-resolution scans of full battery cells and modules

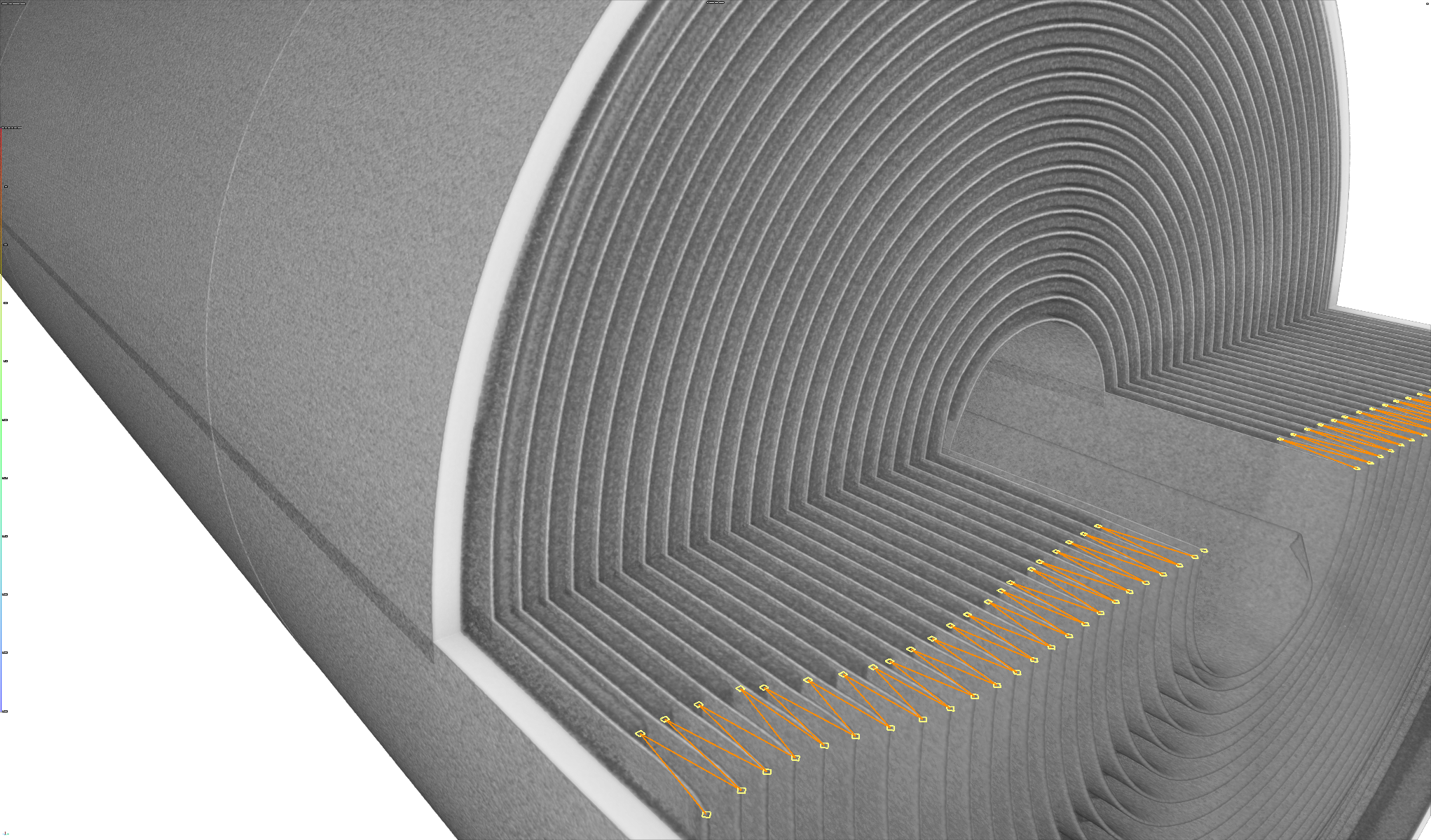

- Fast reconstruction of internal components with no sectioning required

- Suitable for inspection of tab structure, cap assembly, and layer alignment

- Seamless workflow with segmentation and analysis in VGSTUDIO MAX

.webp?width=320&height=313&name=Nov%C3%BD%20projekt%20(5).webp)

.webp?width=314&height=302&name=Nov%C3%BD%20projekt%20(6).webp)