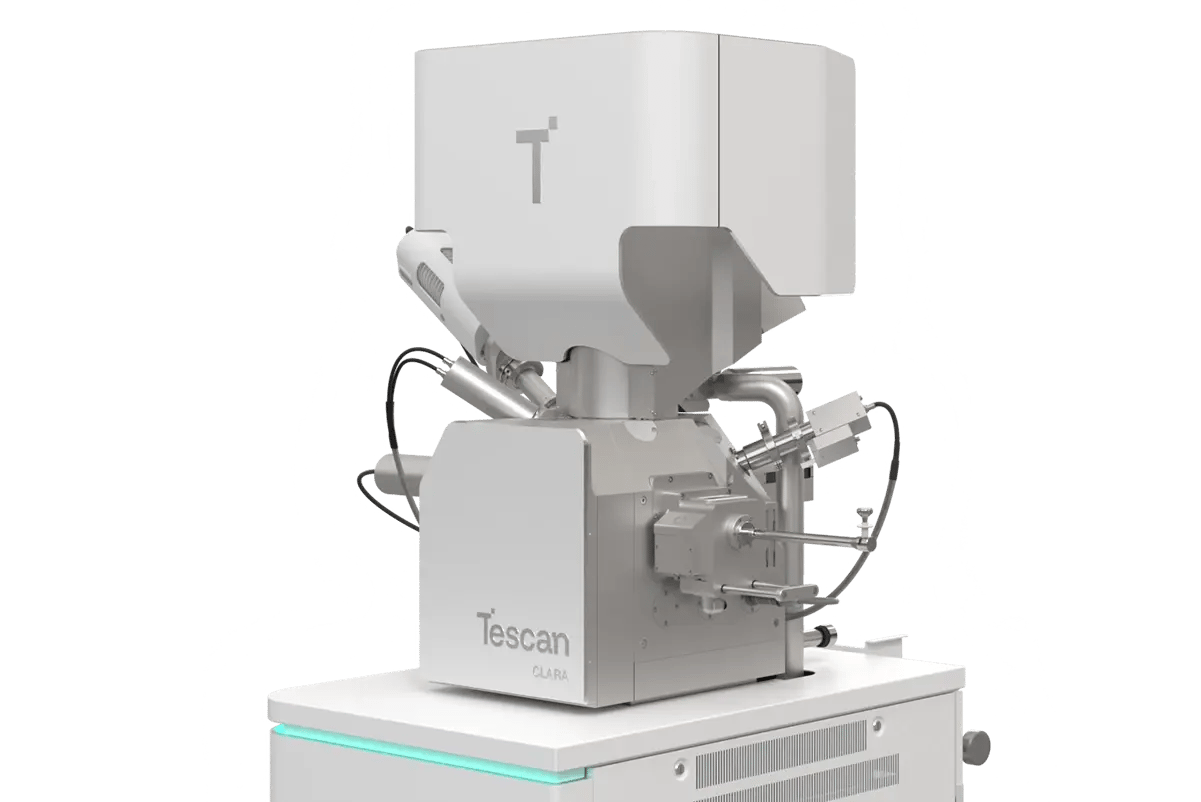

Tescan CLARA

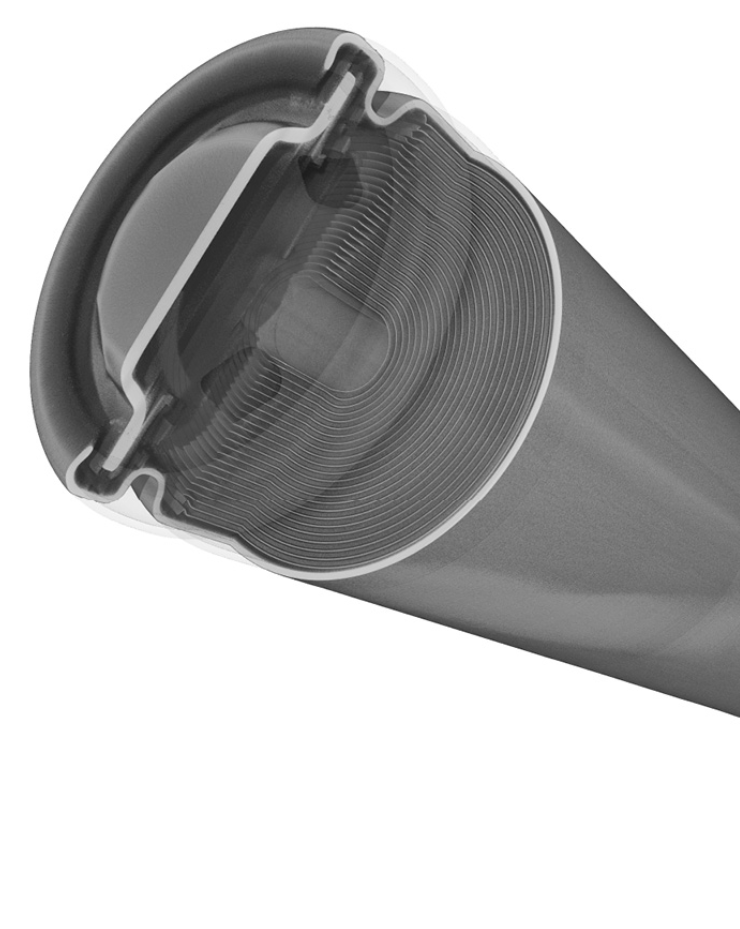

Tescan CLARA provides high-resolution imaging without magnetic interference, making it ideal for sensitive battery materials. Its automated workflows and contrast flexibility allow precise analysis of powder morphology, particle distribution, and surface texture.