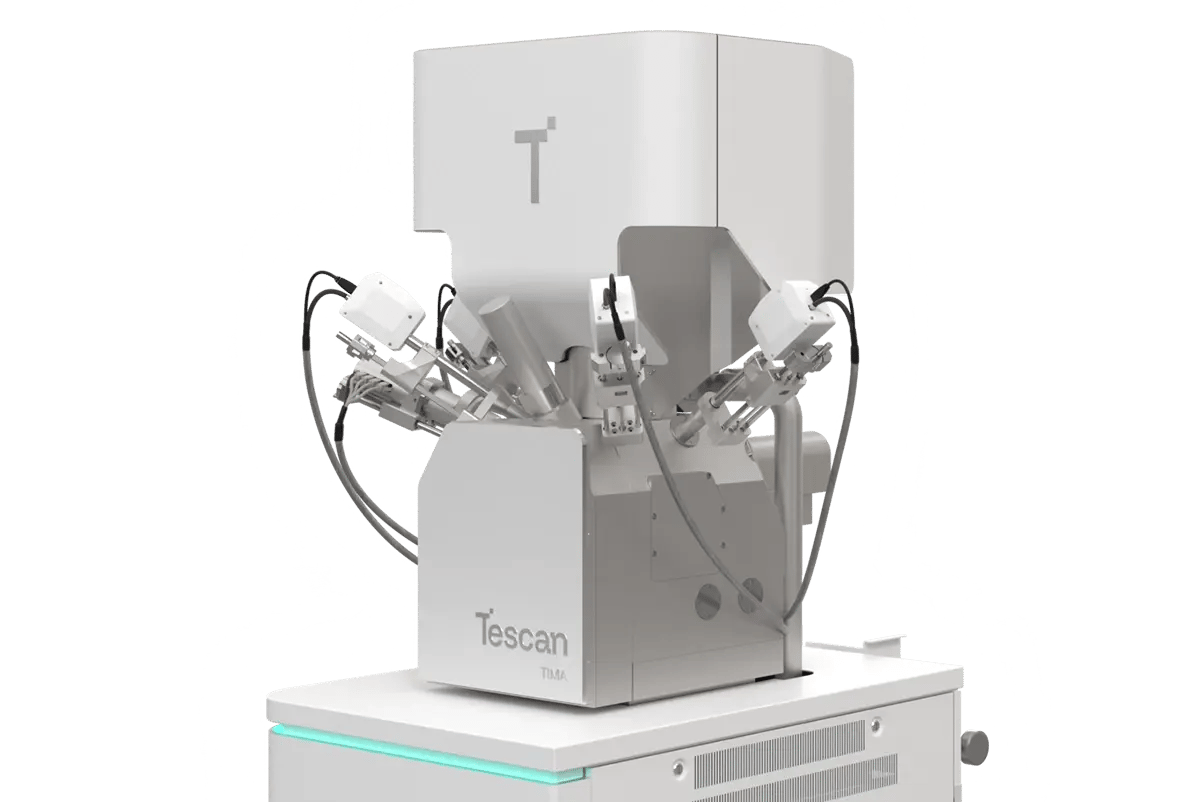

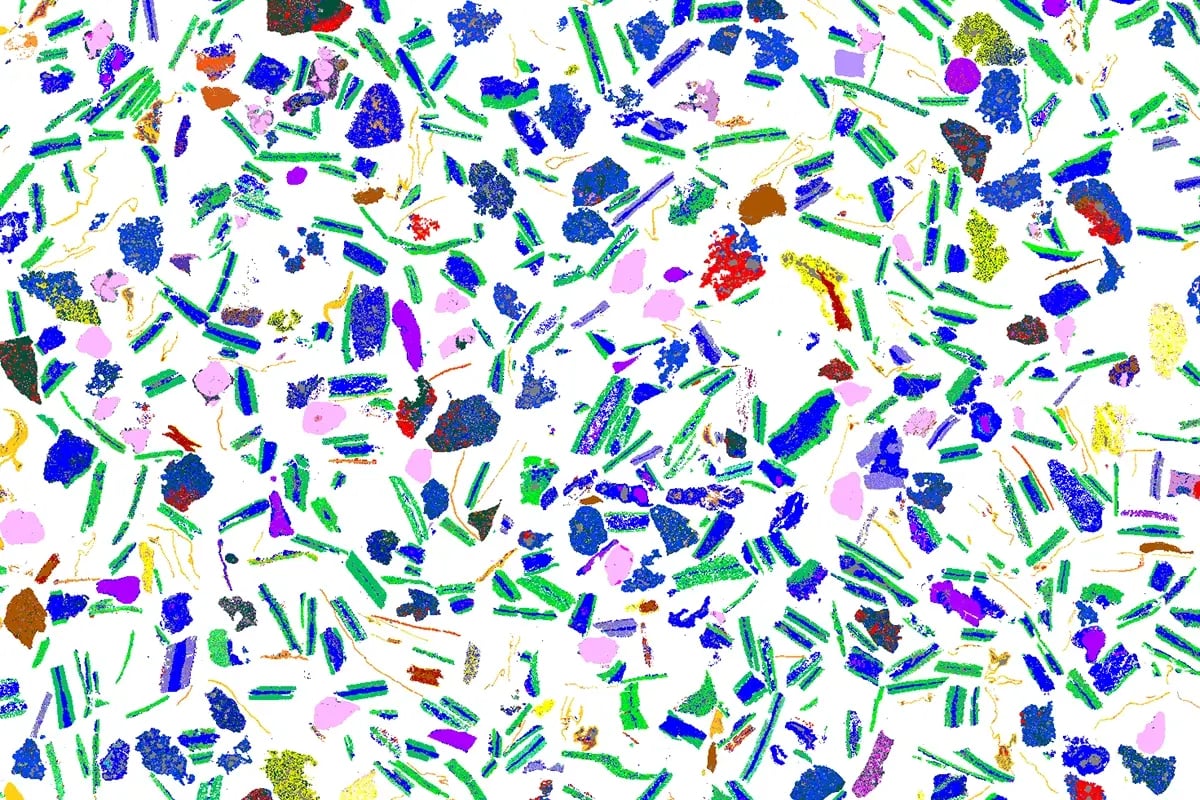

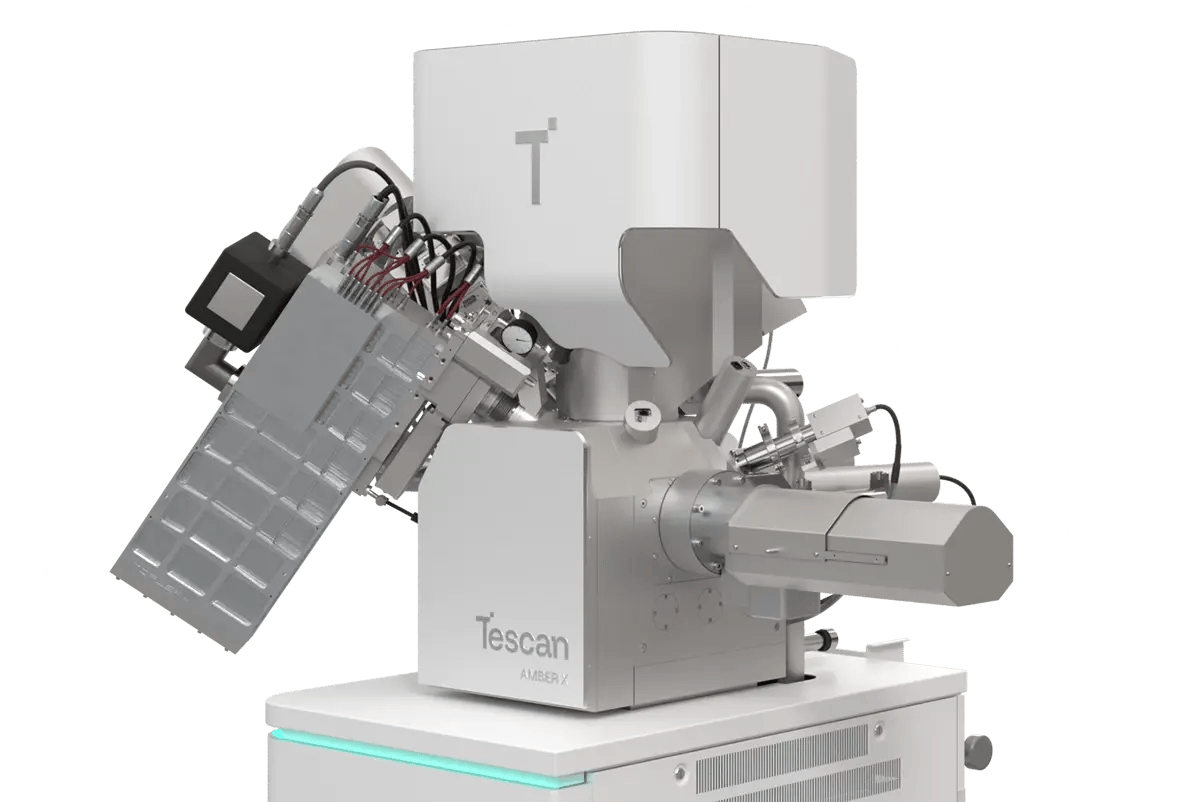

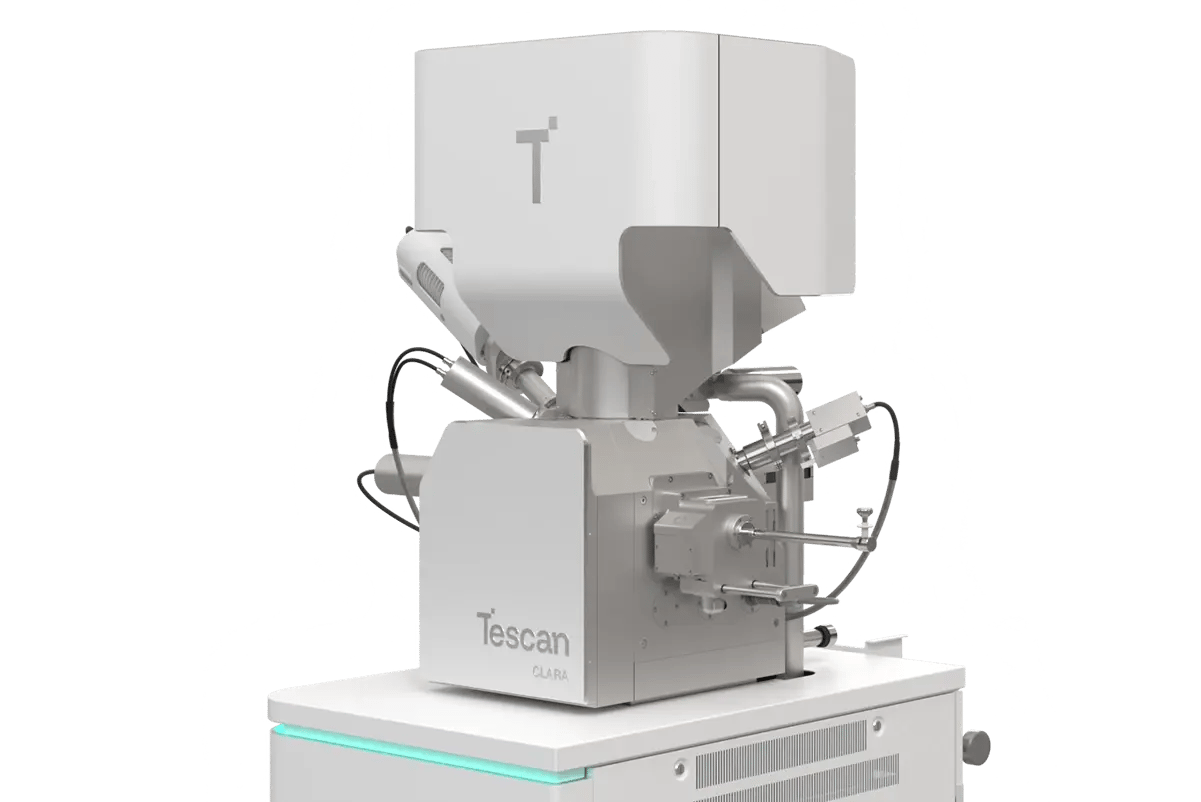

Drive battery innovation with advanced analytical workflows that reveal composition from the nanoscale to full-cell architecture. Tescan imaging and analysis solutions correlate morphology with chemical state and phase composition, enable real-time observation of dynamic processes, and provide quantitative mapping of material structures — supporting the development of safer, longer-lasting, and higher-performing batteries.

FIB-SEM with integrated ToF-SIMS exposes electrode formation and solid-state interfaces, while 4D-STEM resolves crystallographic phases and strain at the nanometer scale. In situ micro-CT complements these insights by tracking electrolyte movement and thermal effects in intact cells.

Deliver reliable results that accelerate material discovery, guide cell design, and shape the next generation of battery technologies.

.webp?width=1032&height=680&name=1_Surface%20examination%20of%20exfoliation%20signs%20on%20degraded%2c%20cycled%20graphite%20anode%20particles%20(1).webp)

-1.webp?width=1201&height=802&name=MICRO_UniTOM_XL_1%20(1)-1.webp)