Tescan UniTOM HR

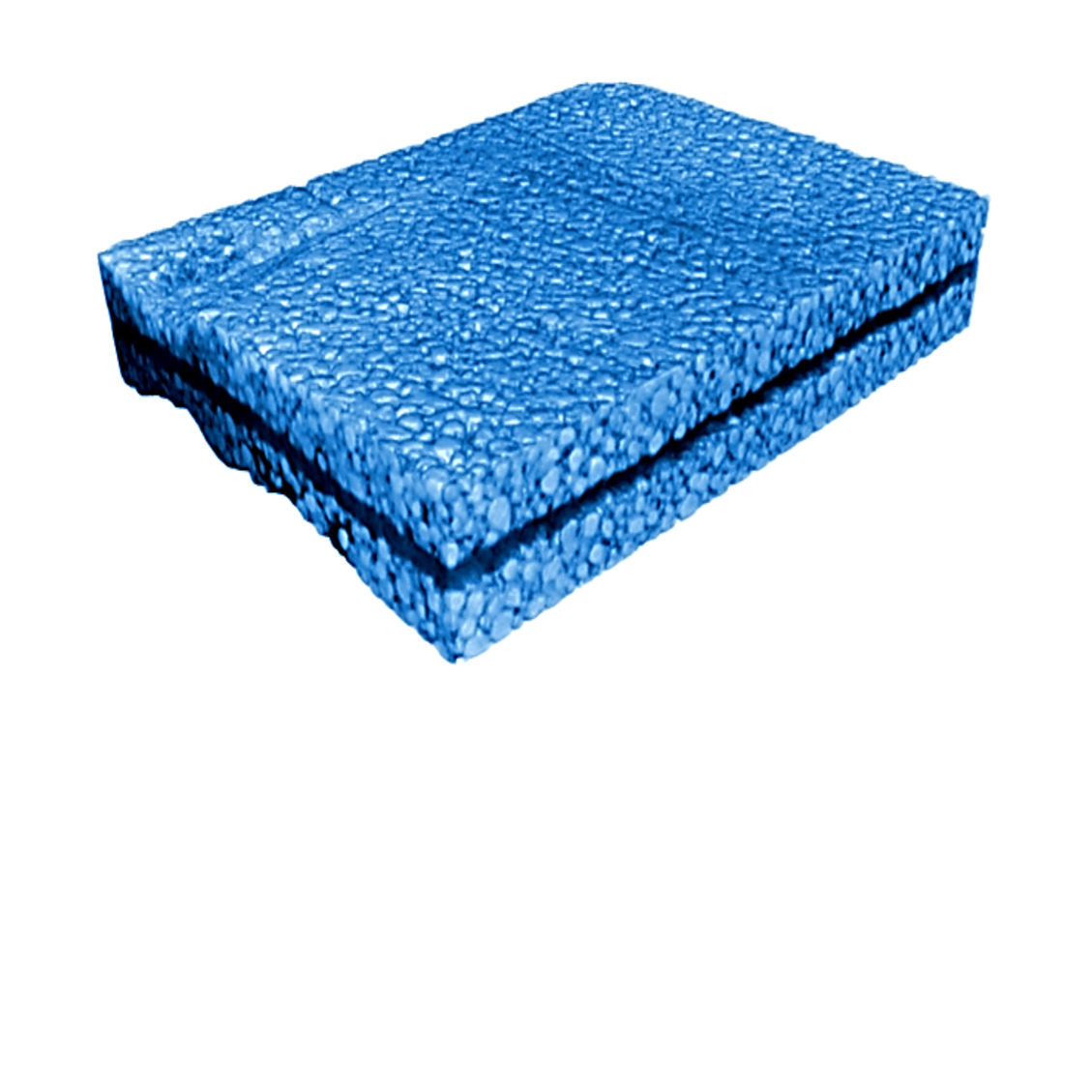

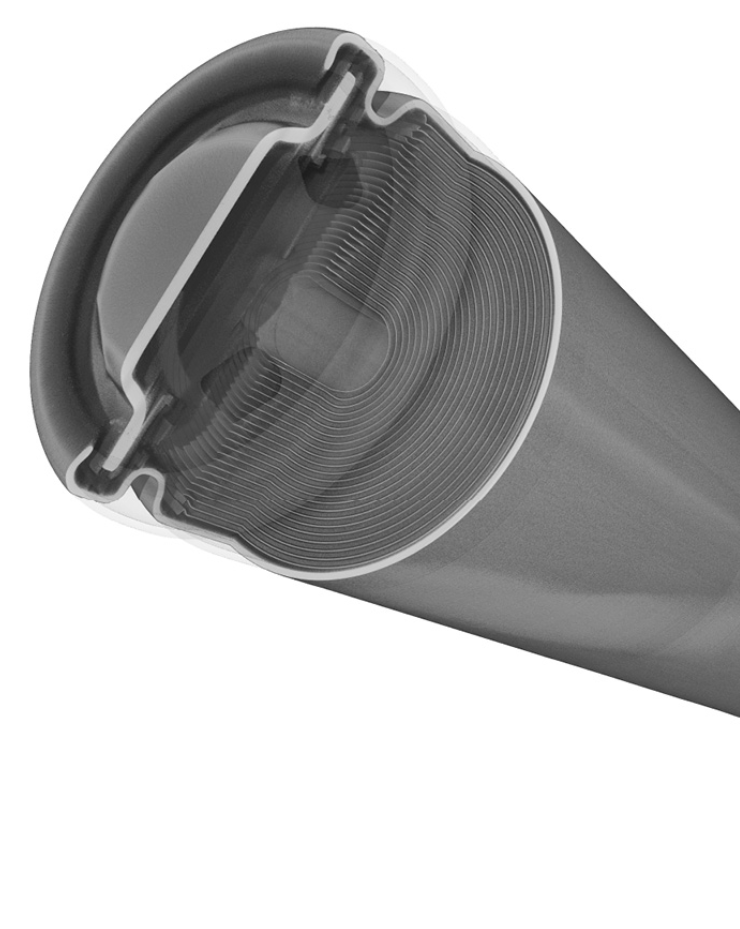

Tescan UniTOM HR offers non-destructive, multiscale imaging for battery cells, modules, and materials — from macro inspection to sub-micron porosity analysis.

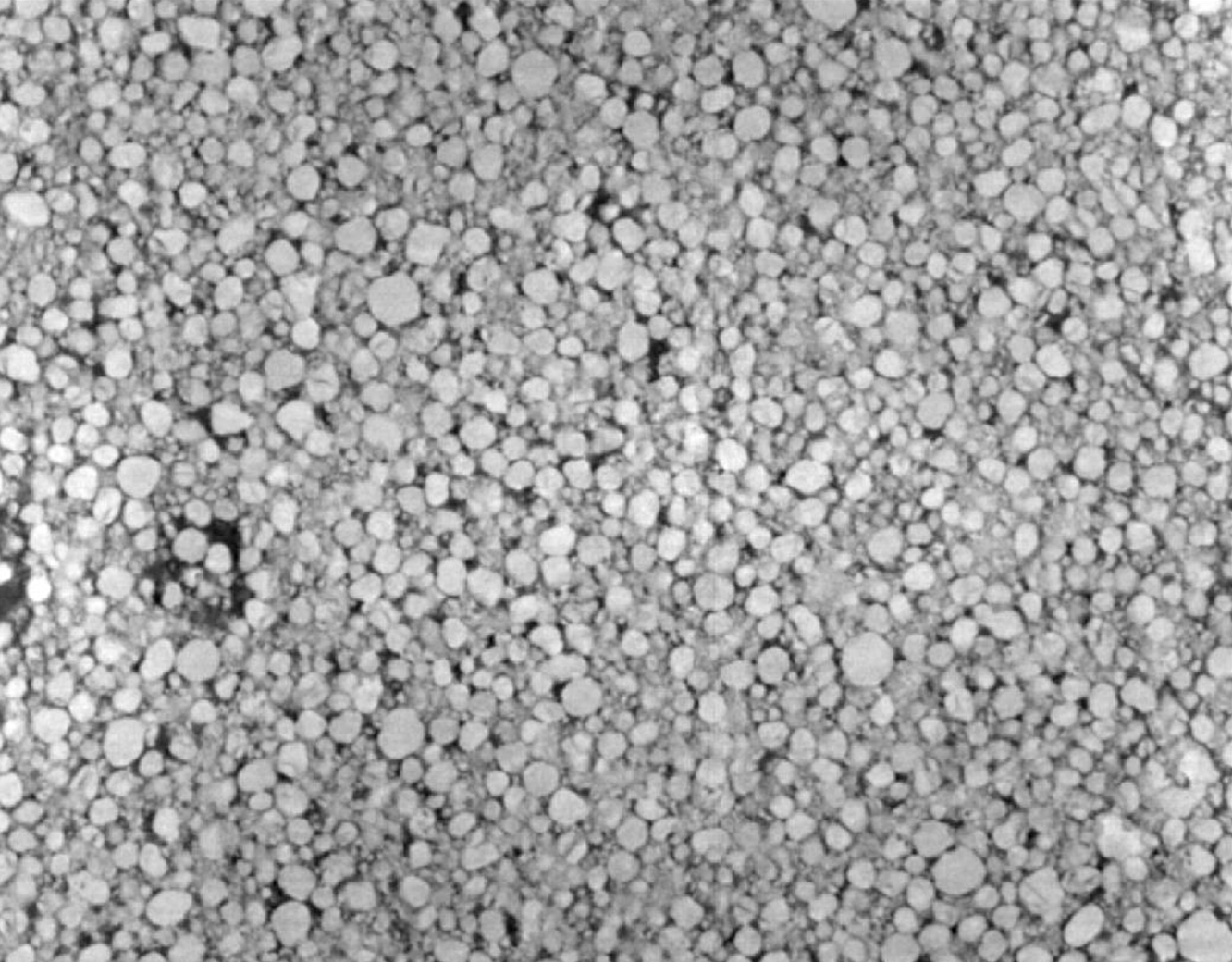

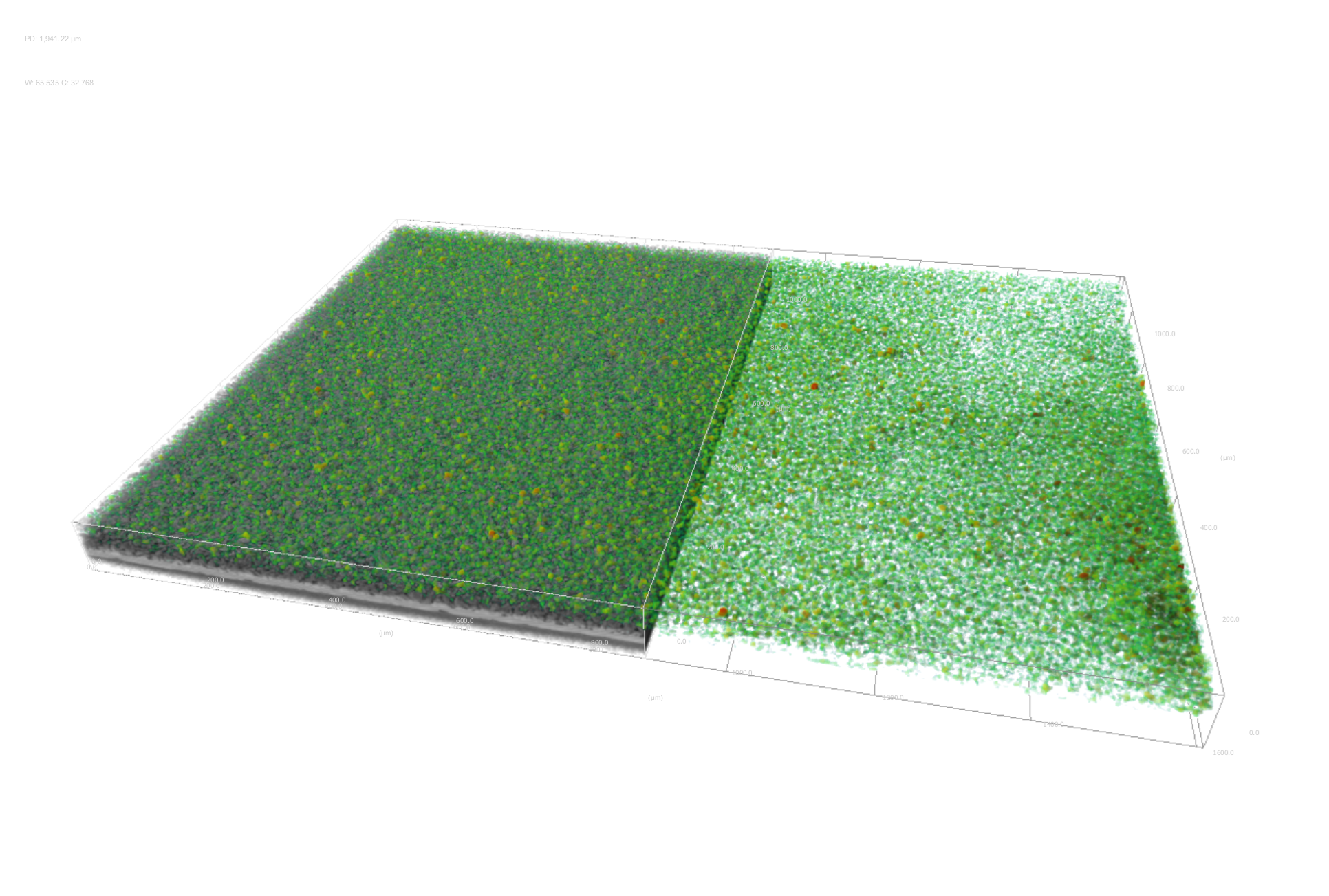

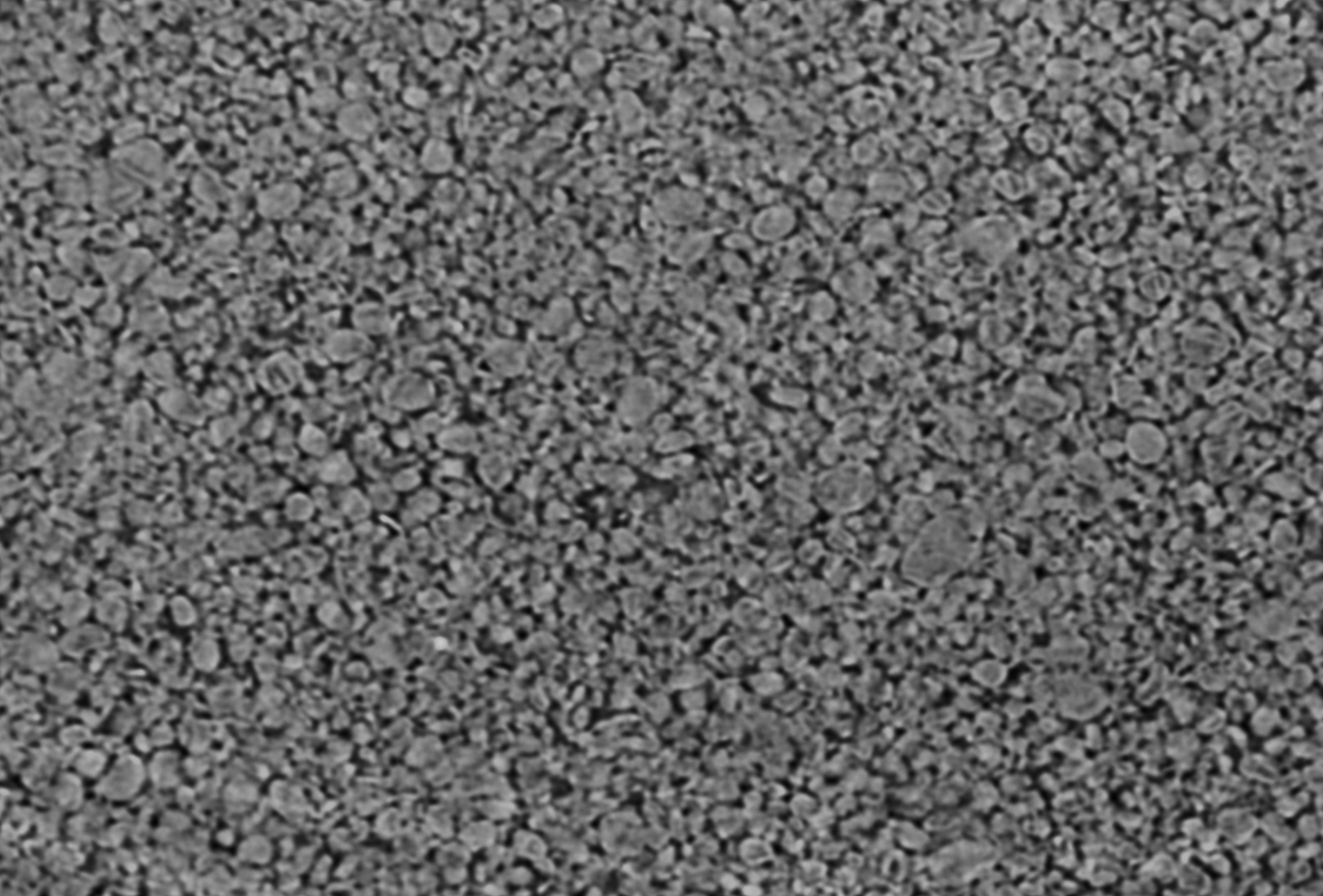

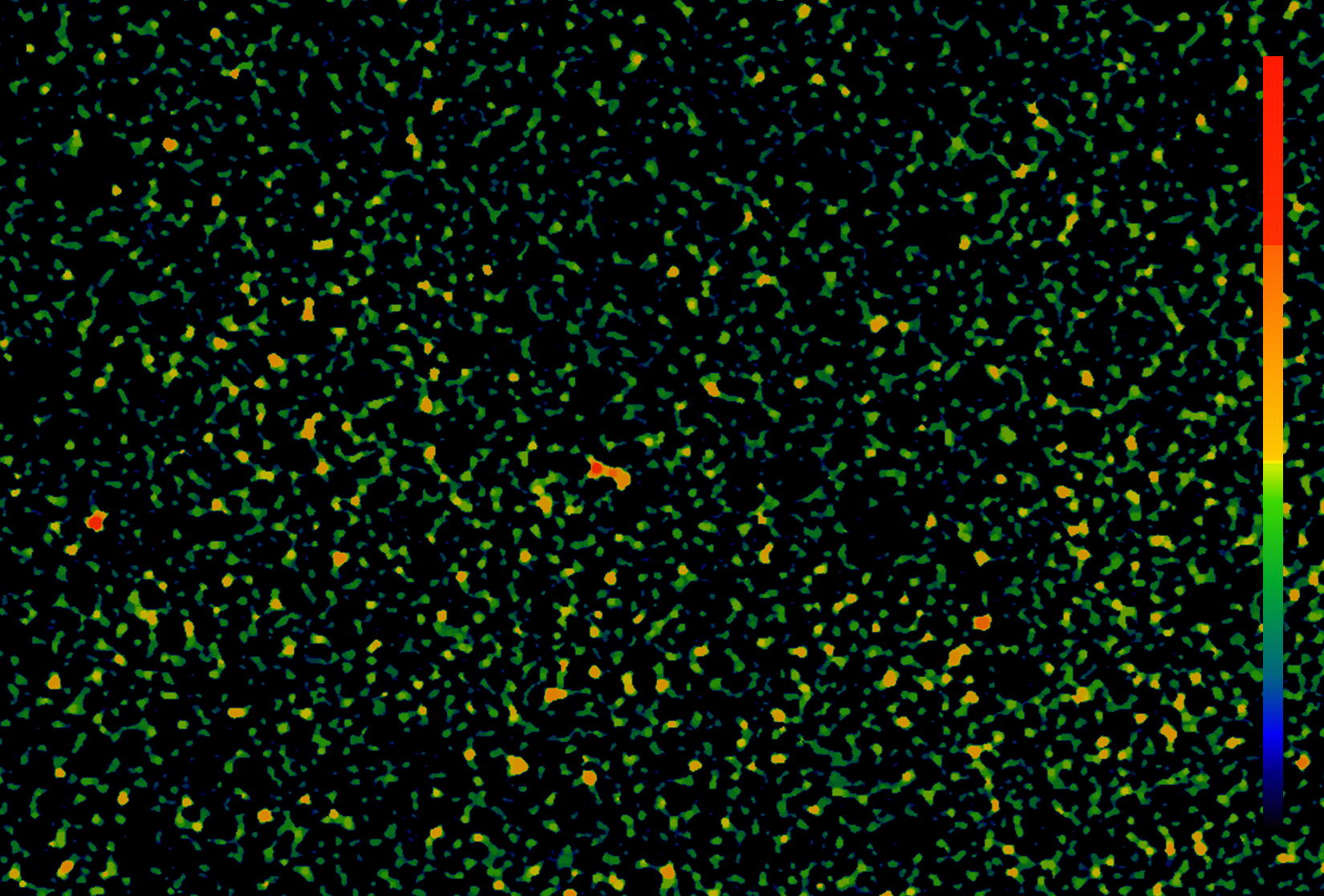

- Sub-micron voxel resolution with high-speed scanning

- Multiscale Volume of Interest (VOI) workflows for targeted analysis

- Ideal for evaluating electrodes, separators, and full cell assemblies