Tescan CLARA

A precision SEM platform designed for low voltage operation and exceptional surface contrast.

-

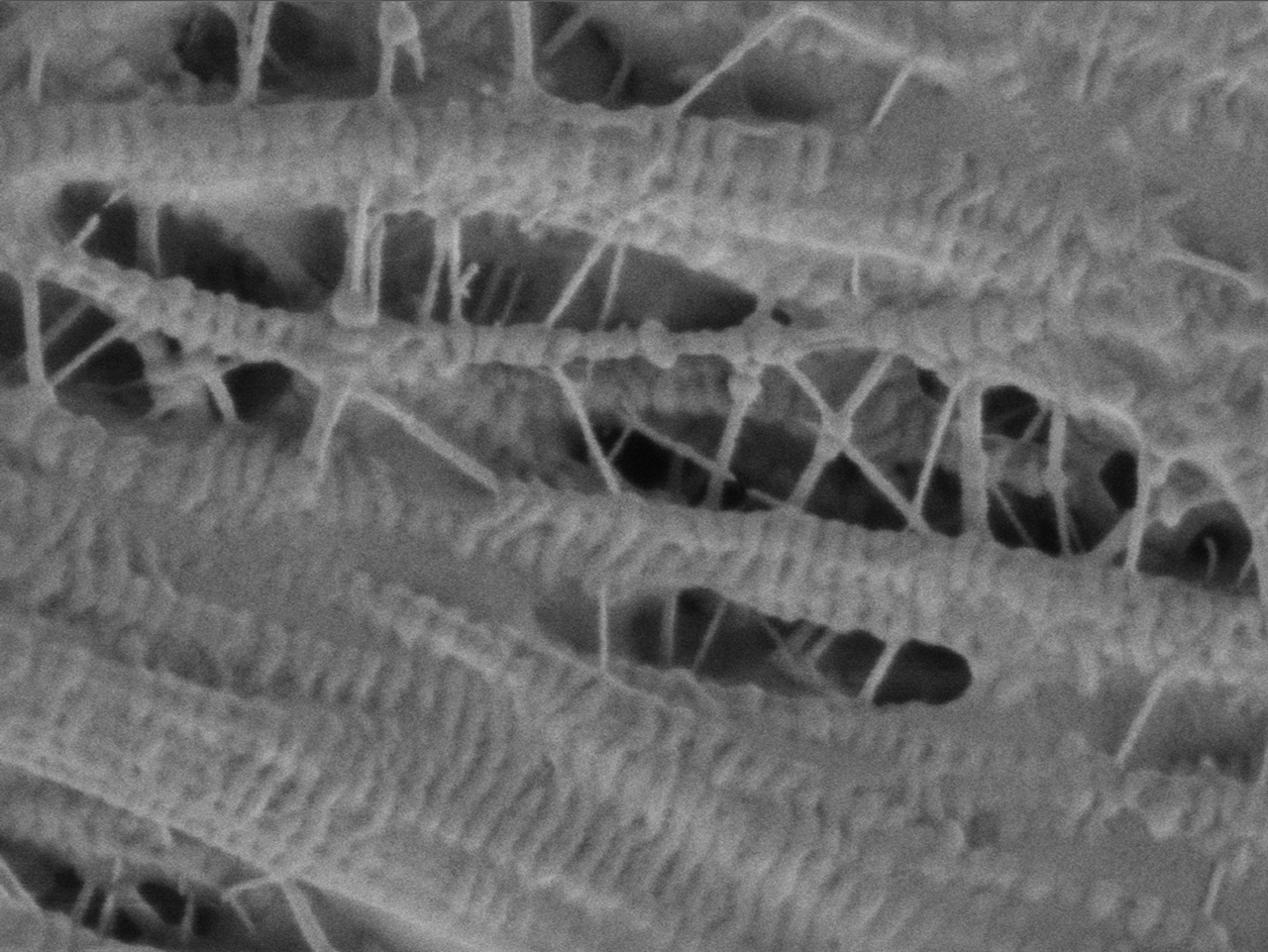

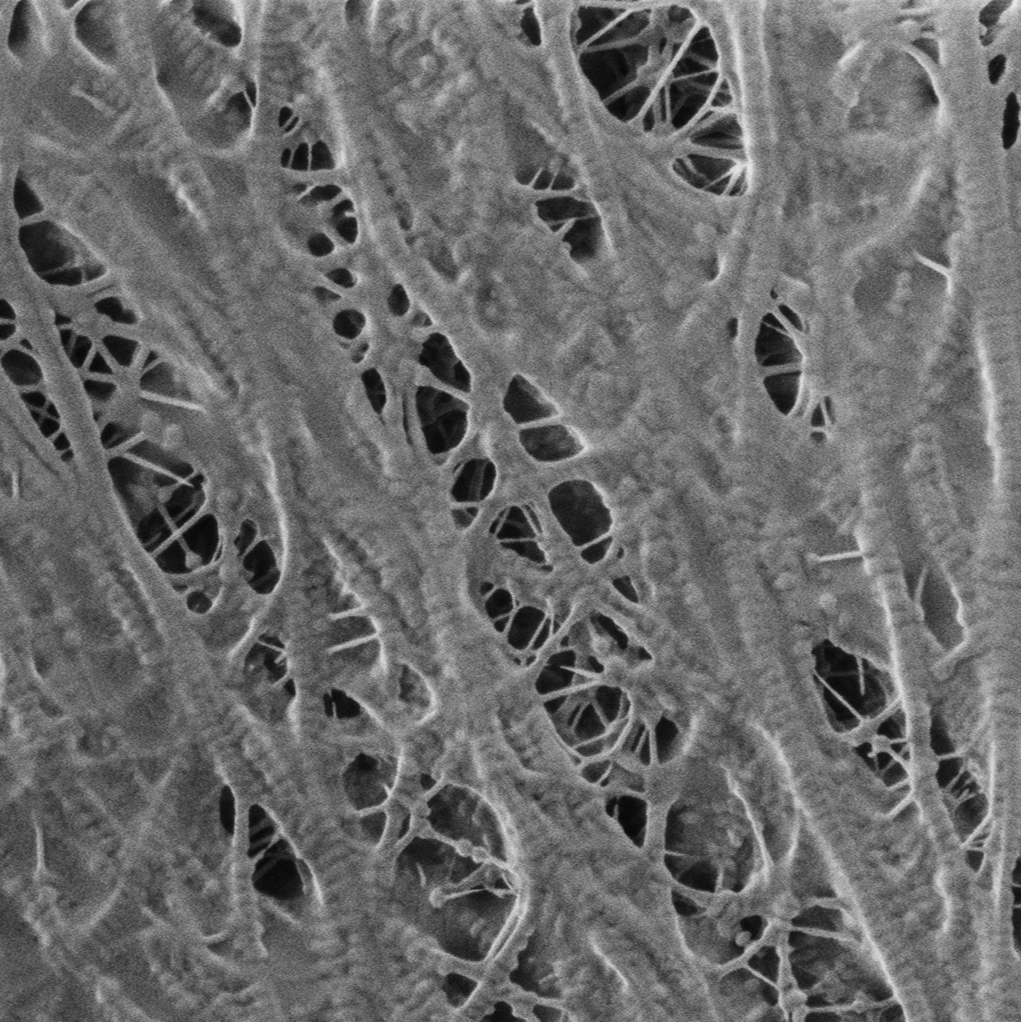

Performs at low voltages to preserve beam-sensitive materials

-

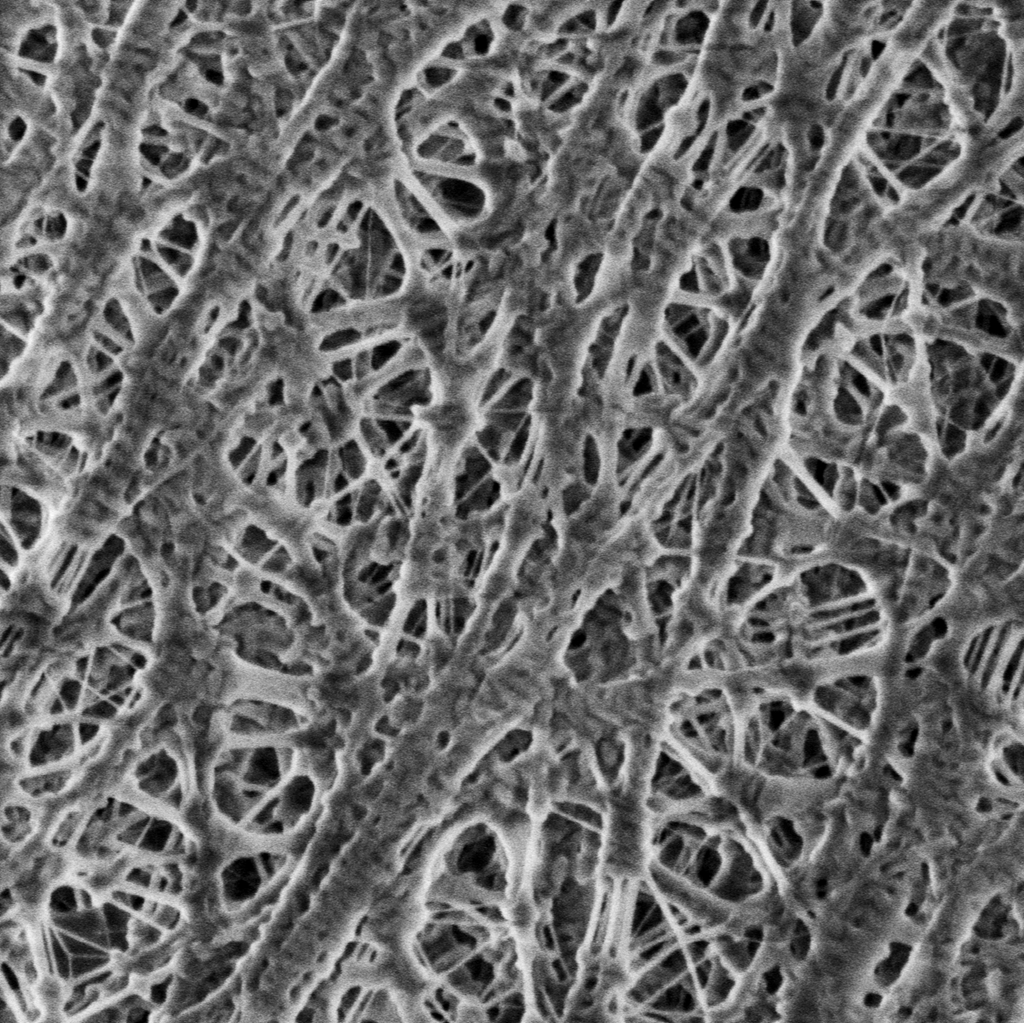

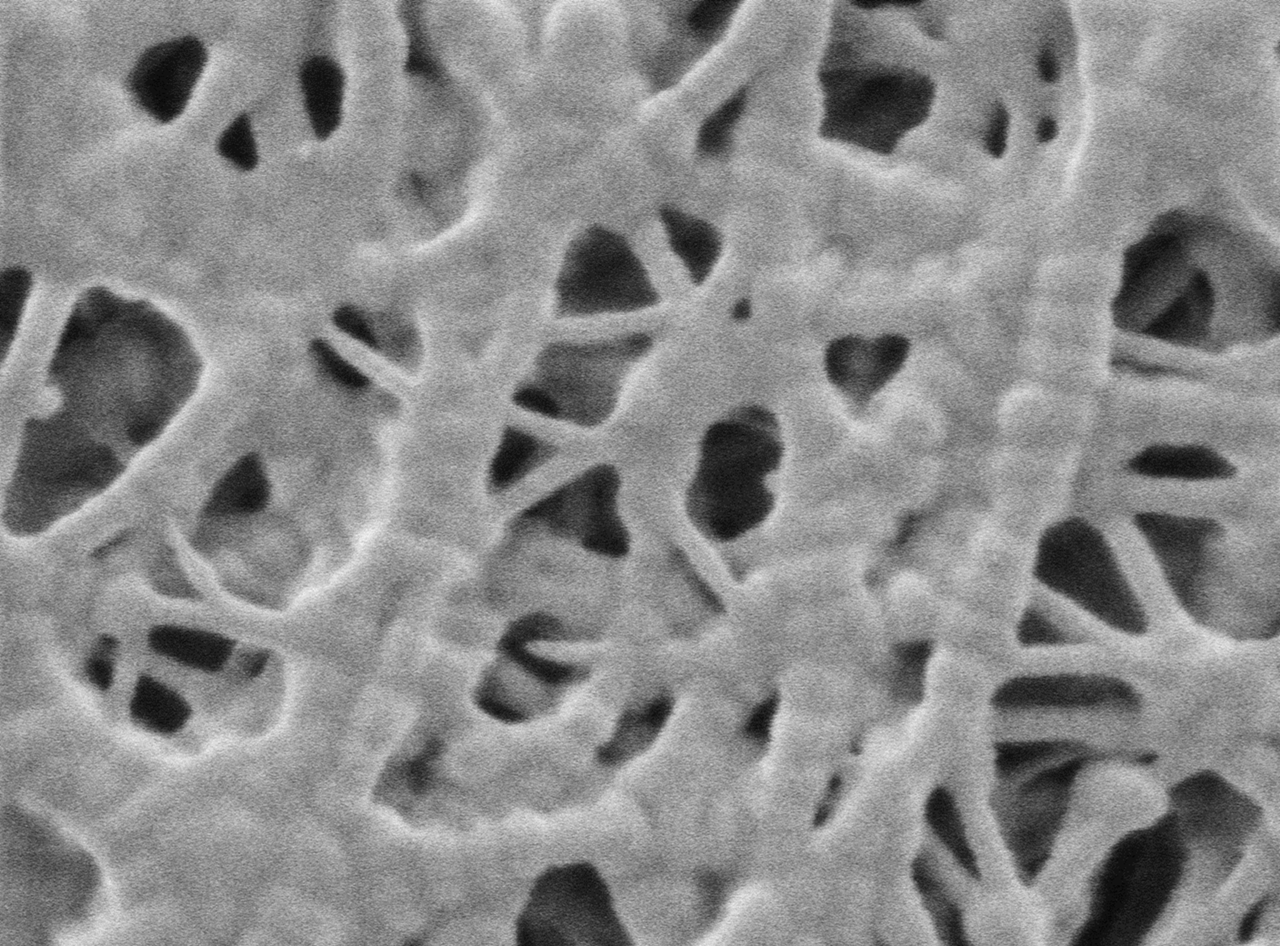

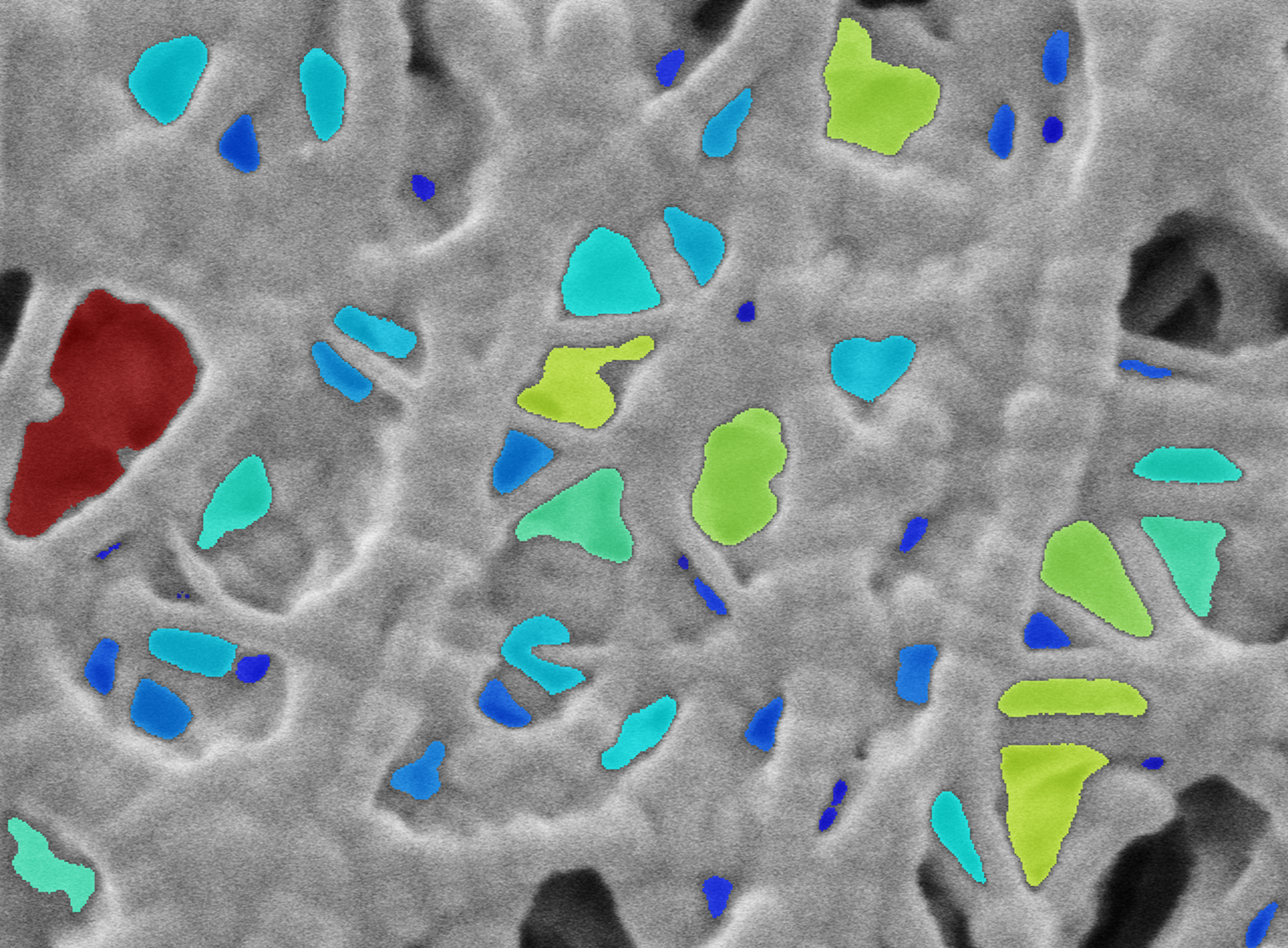

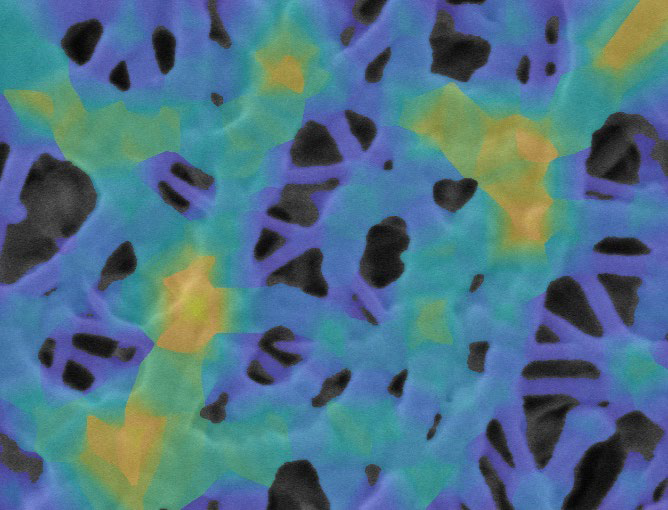

Delivers clear imaging of uncoated polymers and composites

-

Ideal for porous membranes, fibrous films, and soft nanostructures