Tescan CLARA

Versatile UHR field emission SEM tailored for high-detail imaging and crystallographic workflows.

-

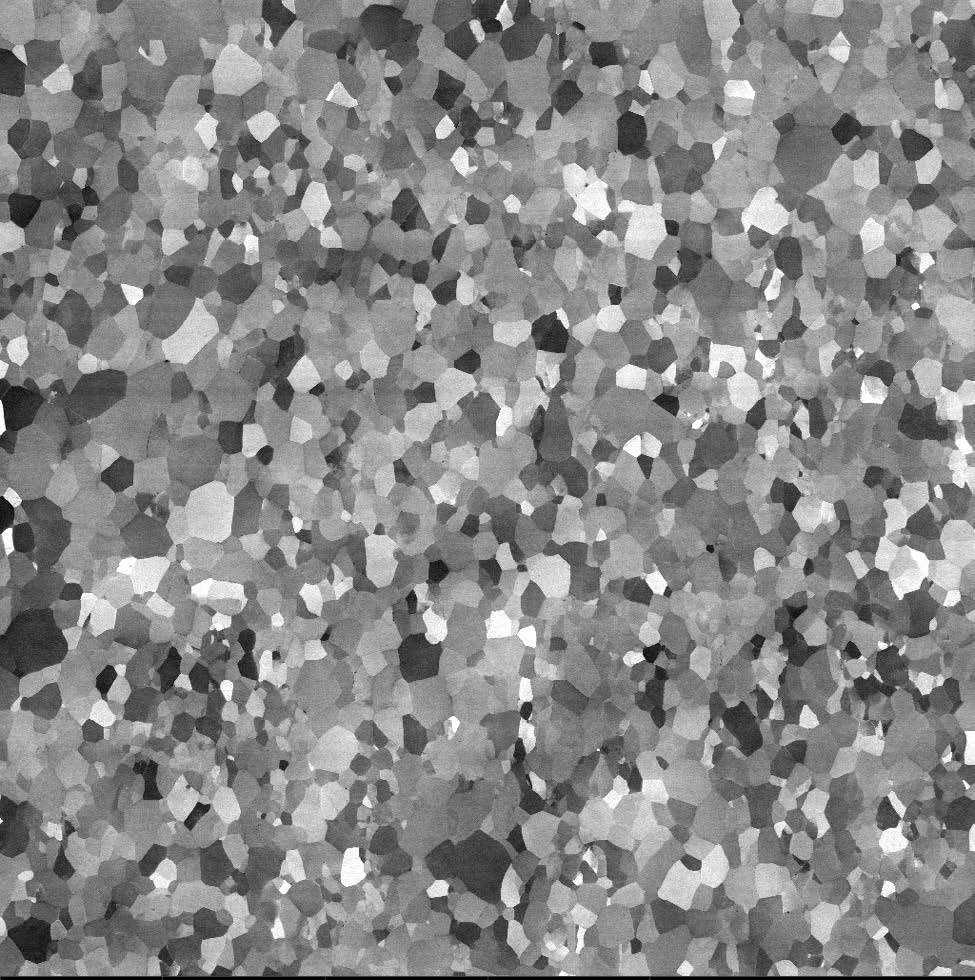

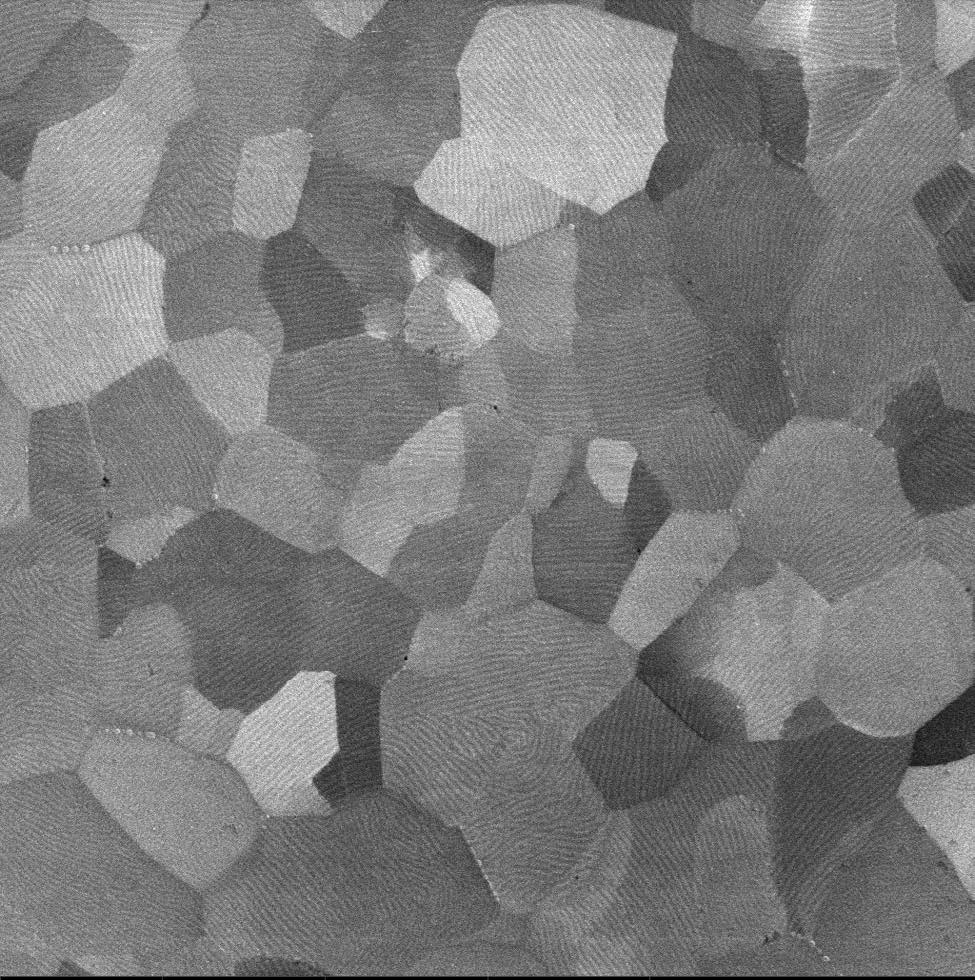

In-chamber BSE detection for channeling contrast

-

BrightBeam™ technology for high resolution field free analysis

-

WideField OpticsTM for fast, high resolution EBSD mapping

-

Scintilator BSE detector for efficient channeling contrast detection

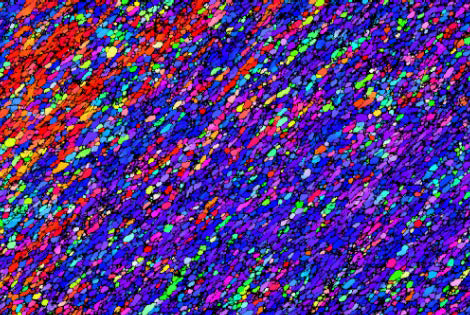

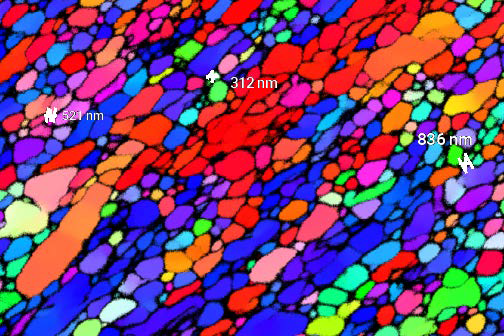

EBSD Mapping: Accelerate Crystallographic Structure Determination

-

Fast, high resolution EBSD data acquisition from large areas

-

Delivers statistically relevant grain orientation data

-

Delivers accurate orientation and boundary maps

-

Ideal for evaluating deformation patterns and process outcomes