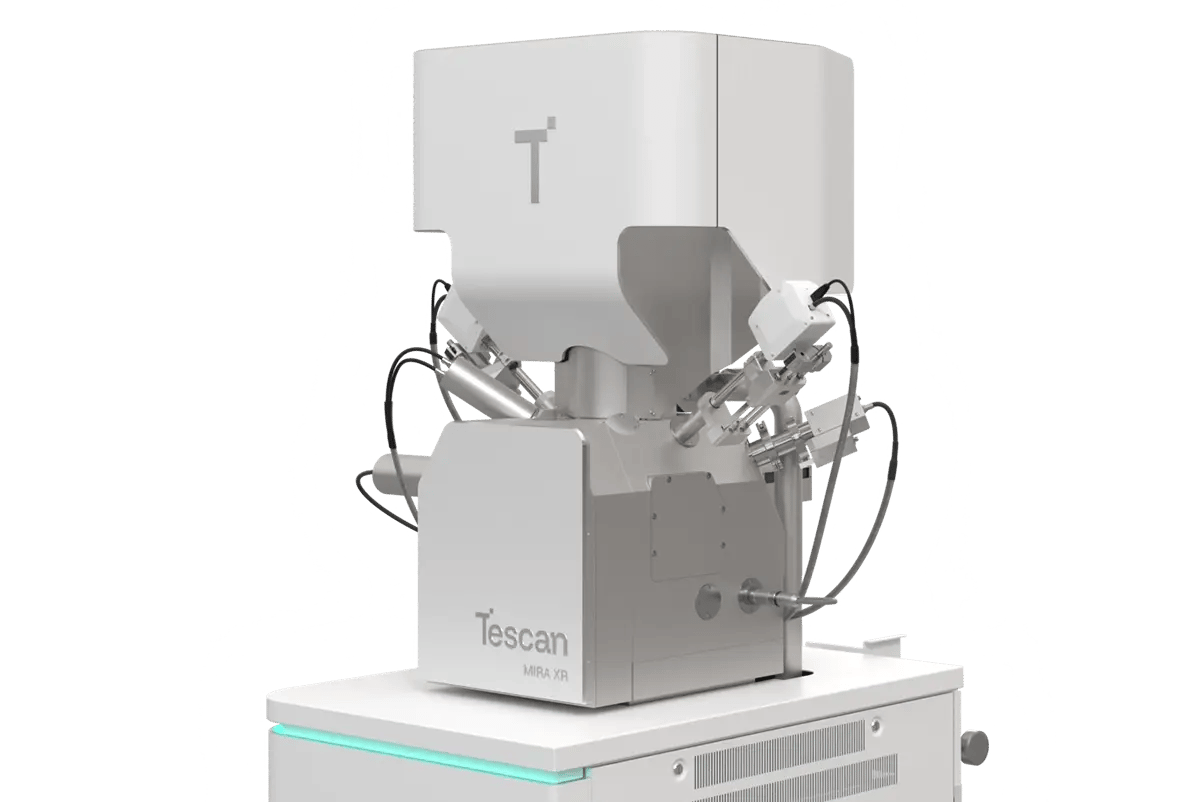

Tescan CLARA

Combines sub-nanometer resolution with advanced analytics.

-

High-quality BSE contrast for phase discrimination

-

Low-kV imaging for detailed grain and substructure observation

-

Full EBSD and EDS compatibility for multimodal studies

-

Automated panoramic imaging for weld zone evaluation