Tescan CLARA

Combines sub-nanometer resolution with advanced analytics and automation

-

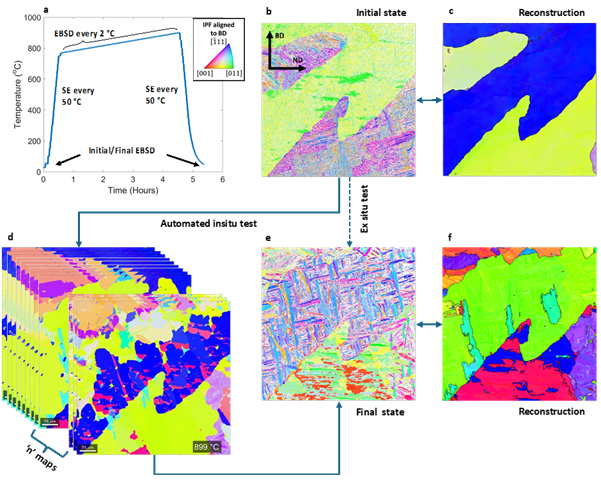

Full integration of in situ heating setup, including imaging and EBSD

-

Automation for days-long, unattended image and EBSD map acquisitions

-

High-quality imaging over long periods, thanks to drift compensation and automatic refocusing

%20inlay%20to%20highlight%20bulging%20of%20recrystallised%20grains%20into%20grains%20undergoing.png?width=762&height=315&name=02_EBSD%20map%20of%20ROI%20at%20810%C2%B0C%3B%20b)%20inlay%20to%20highlight%20bulging%20of%20recrystallised%20grains%20into%20grains%20undergoing.png)