Tescan CLARA

Engineered to reveal surface detail on even the most challenging samples.

-

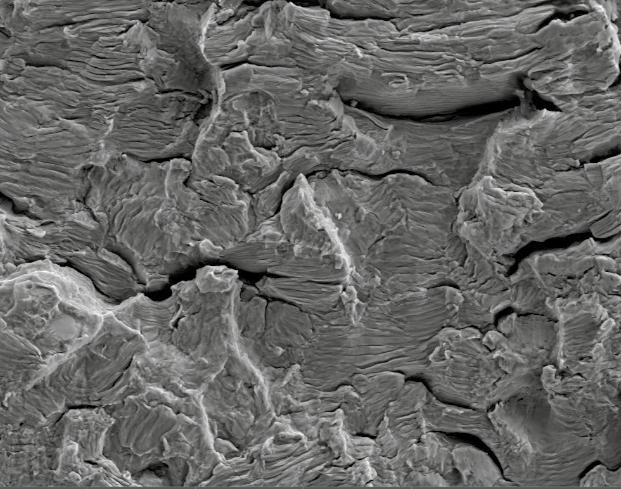

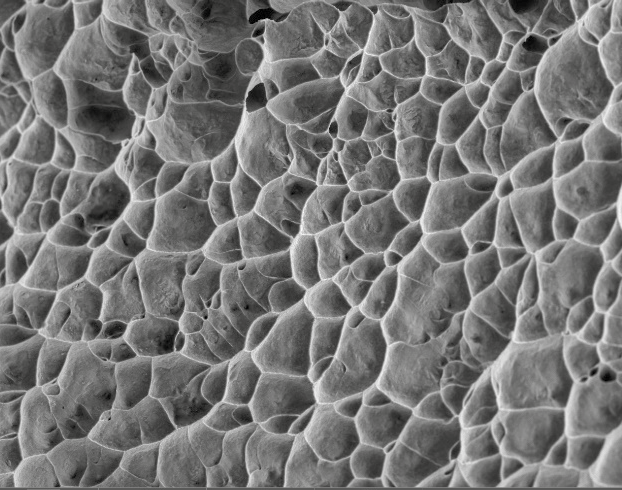

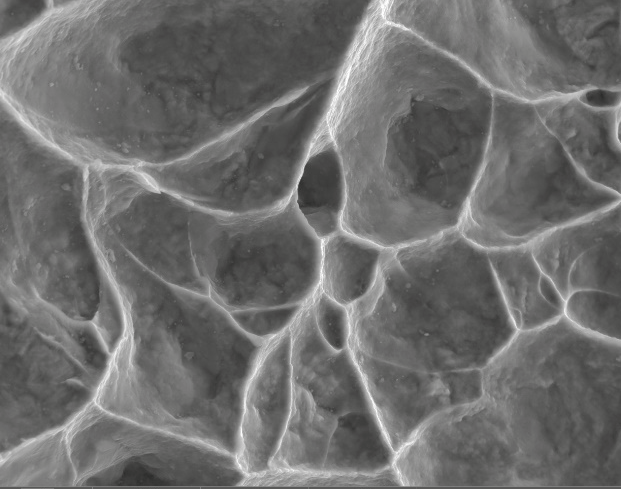

Rough, fractured surfaces in full details with high depth of focus

-

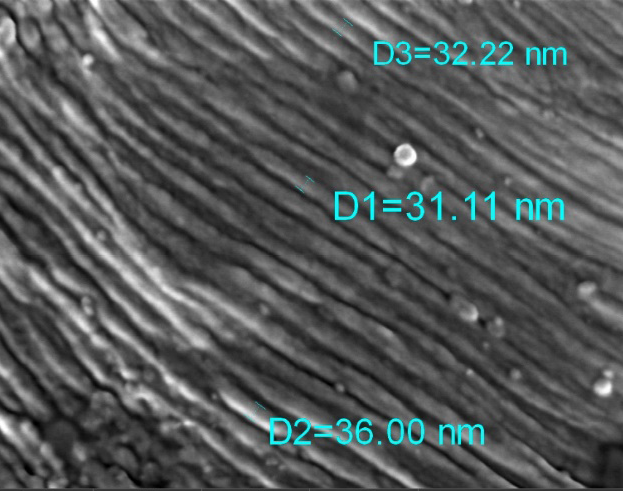

Produces high-contrast SE images with nanometer resolution

-

Low-kV capable for clear imaging of surface details

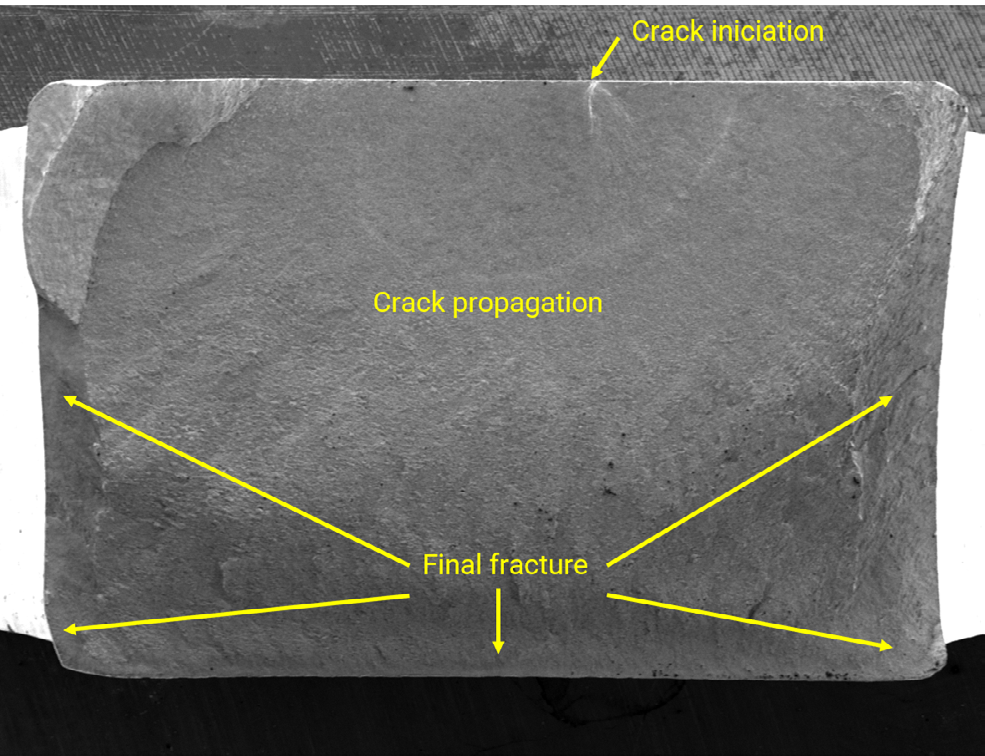

Wide Field™ Mode: Contextual Navigation Across the Sample

Overview imaging mode for full-sample observation, live navigation and seamless transition to high resolution.

-

Large area overview for live navigation

-

Image targeted features of interest without losing spatial reference

-

Especially useful for fracture surface analysis workflows