Tescan MIRA XR

A versatile field emission SEM designed for non-destructive surface imaging and fine structural analysis.

-

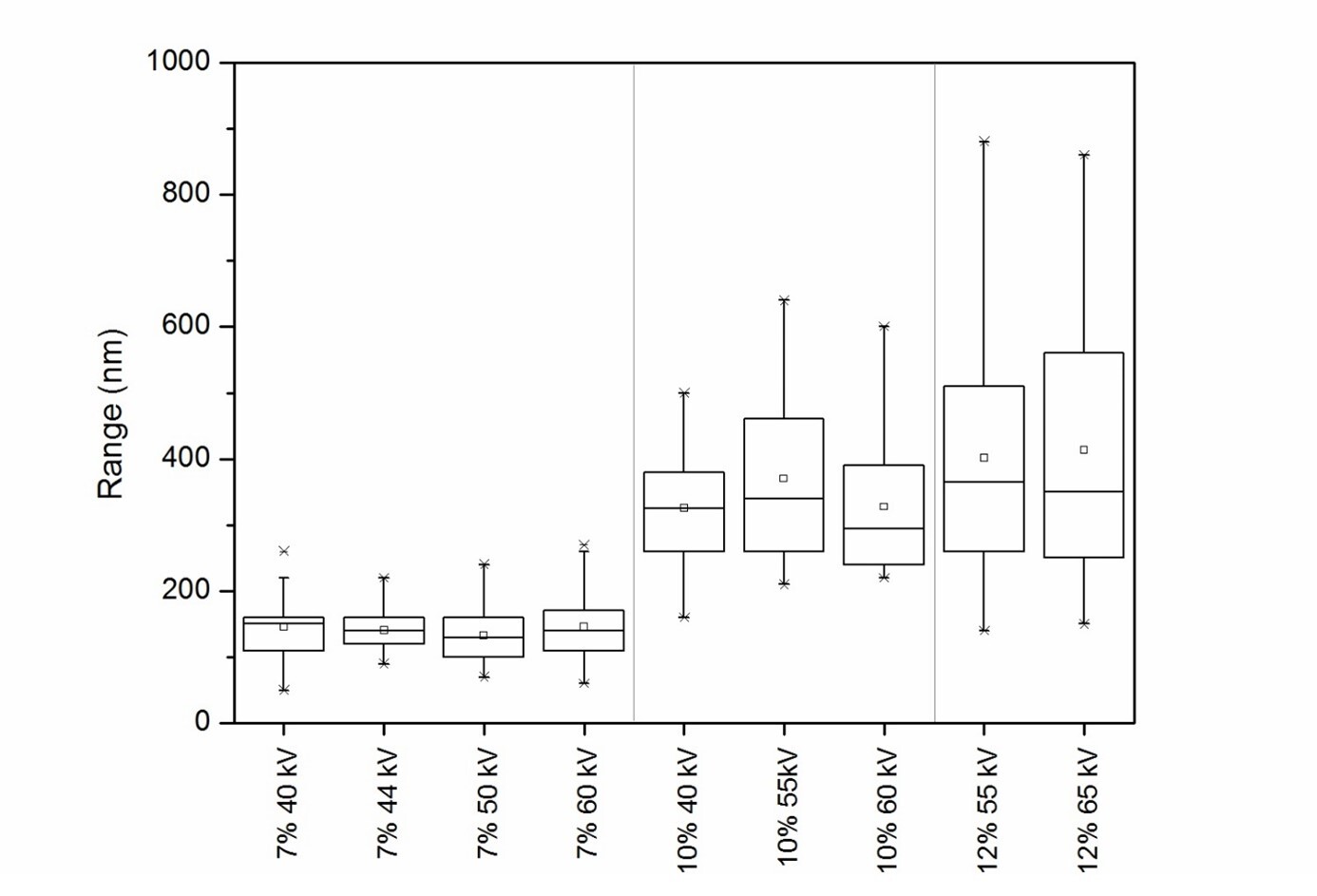

Optimized low-kV performance for polymers and other sensitive materials

-

Wide field-of-view spanning macro to nanoscale

-

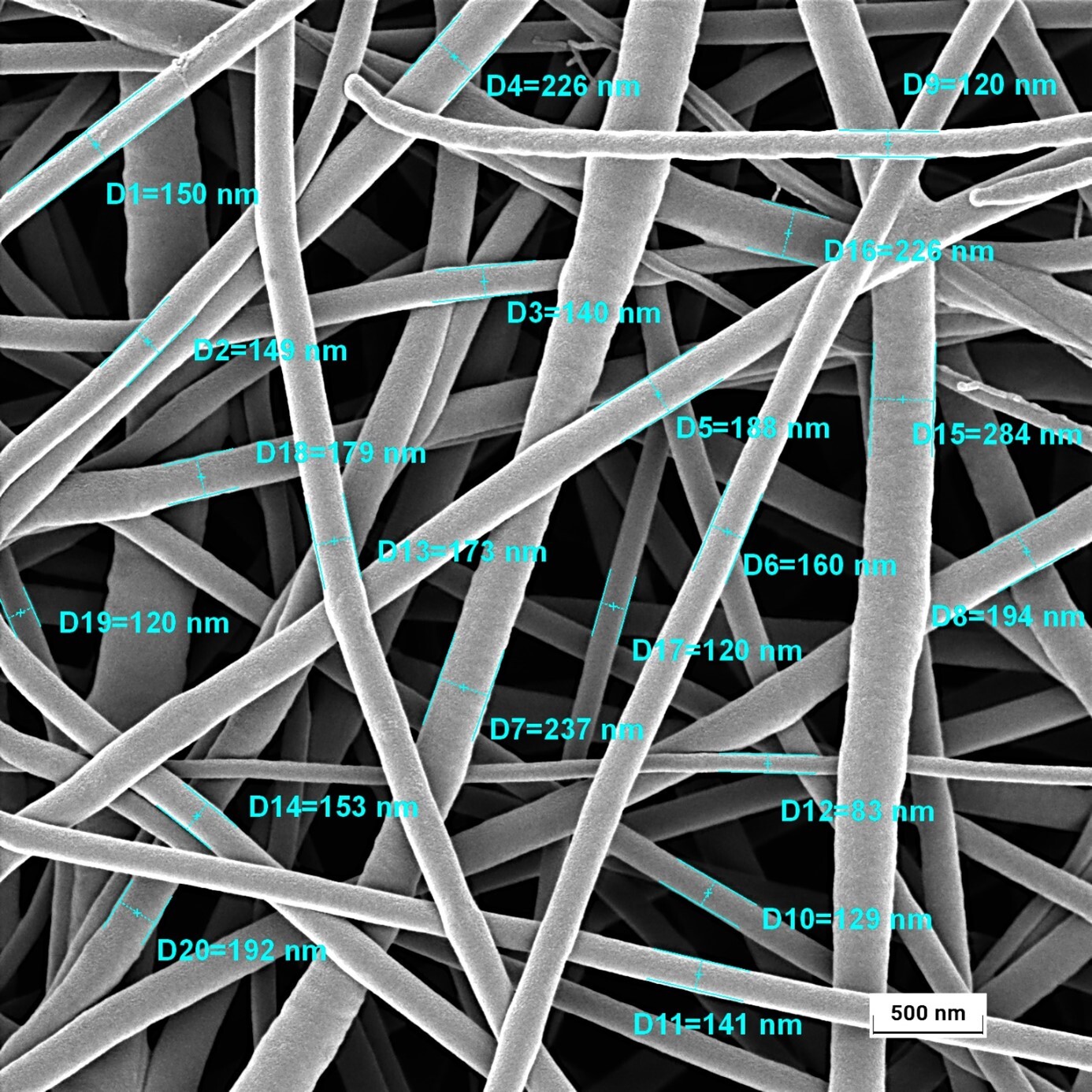

Ideal for morphology assessment of nanofibers, soft composites, and thin coatings