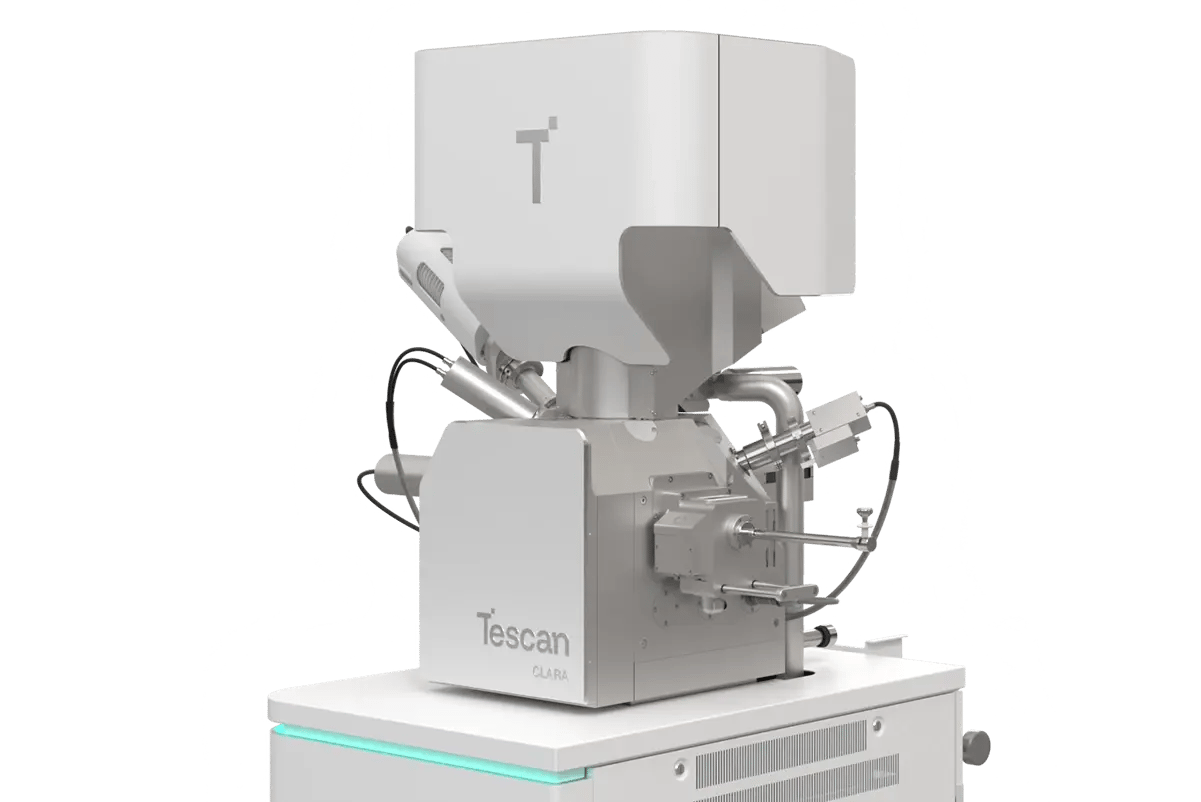

Tescan CLARA

A field emission scanning electron microscope optimized for low-kV imaging and high-contrast surface visualization.

-

Delivers nanometer resolution at low accelerating voltages

-

Ideal for beam-sensitive and nano-structured materials

-

Consistent performance across large samples and multiple scales