TESCAN AMBER X 2

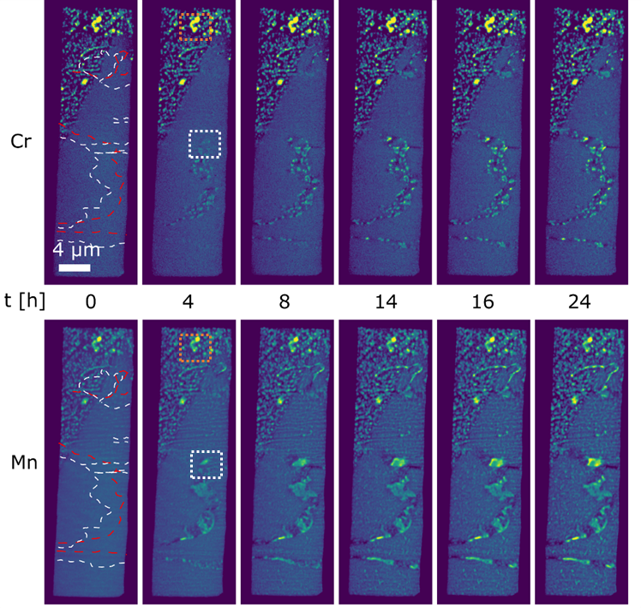

With high-current Xe⁺ ion milling and field-free SEM imaging, TESCAN AMBER X 2 is engineered for sample preparation workflows that require chemical precision and large-volume trenching.

- Ga⁺-free Xe⁺ plasma FIB preserves sample chemistry – ideal for heat-sensitive alloys

- Supports large, artifact-free lamella preparation for in-situ synchrotron workflows

- Field-free UHR SEM imaging ensures topographical and compositional accuracy at microstructural boundaries