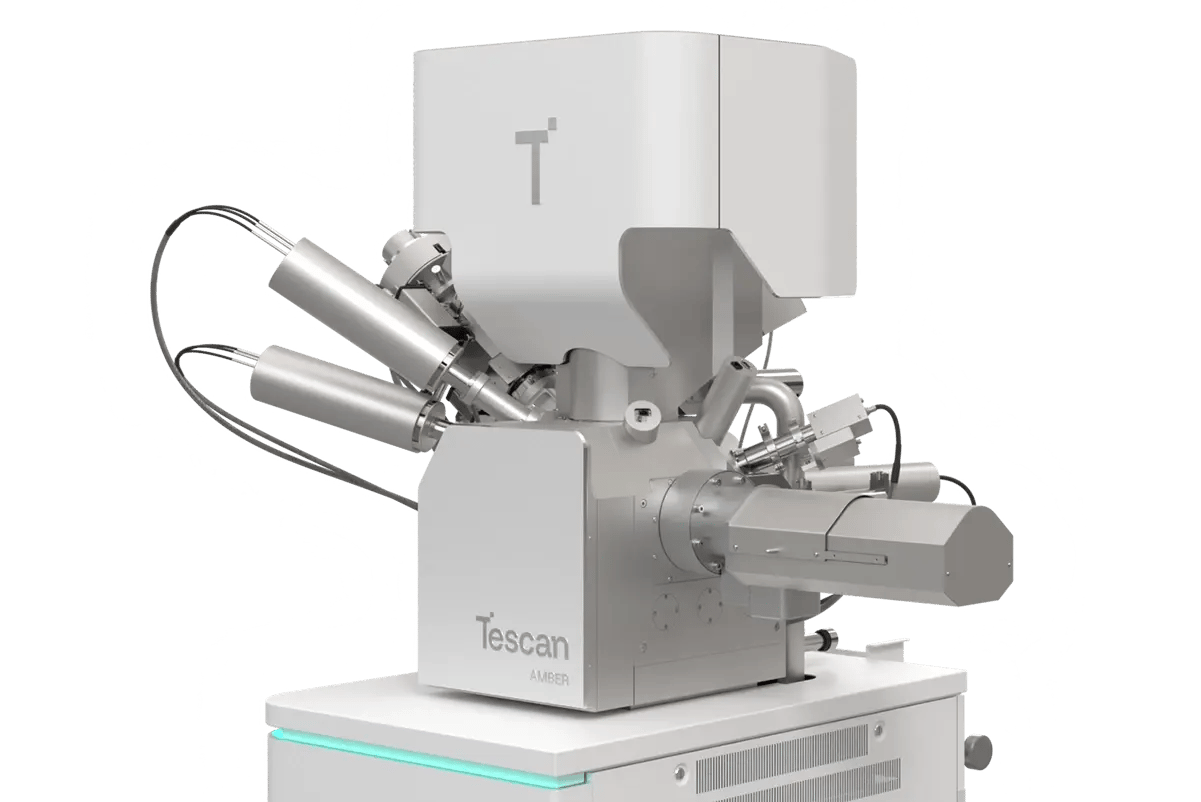

Tescan AMBER 2

A multi-functional Ga FIB-SEM workstation offering high-precision milling, ultra-high-resolution imaging, and advanced automation for materials research and TEM sample prep.

- Gallium FIB for high-precision nanofabrication and TEM lamella preparation

- Field-free UHR SEM column delivers ultra-high-resolution imaging and nanoanalysis

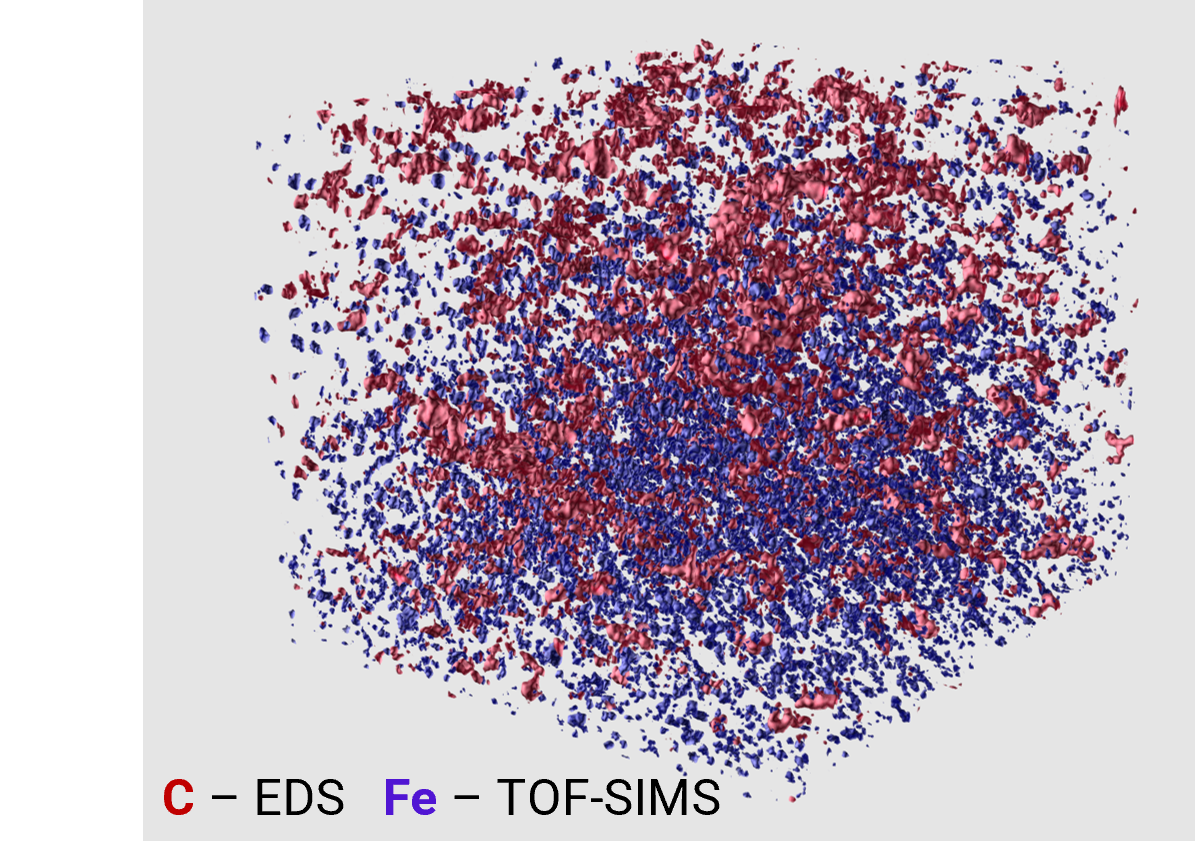

- Multi-site automation and 3D FIB-SEM multimodal tomography, including integrated ToF-SIMS, for comprehensive analysis