TESCAN TENSOR

A fully integrated analytical STEM system optimized for high-resolution crystallographic and structural analysis.

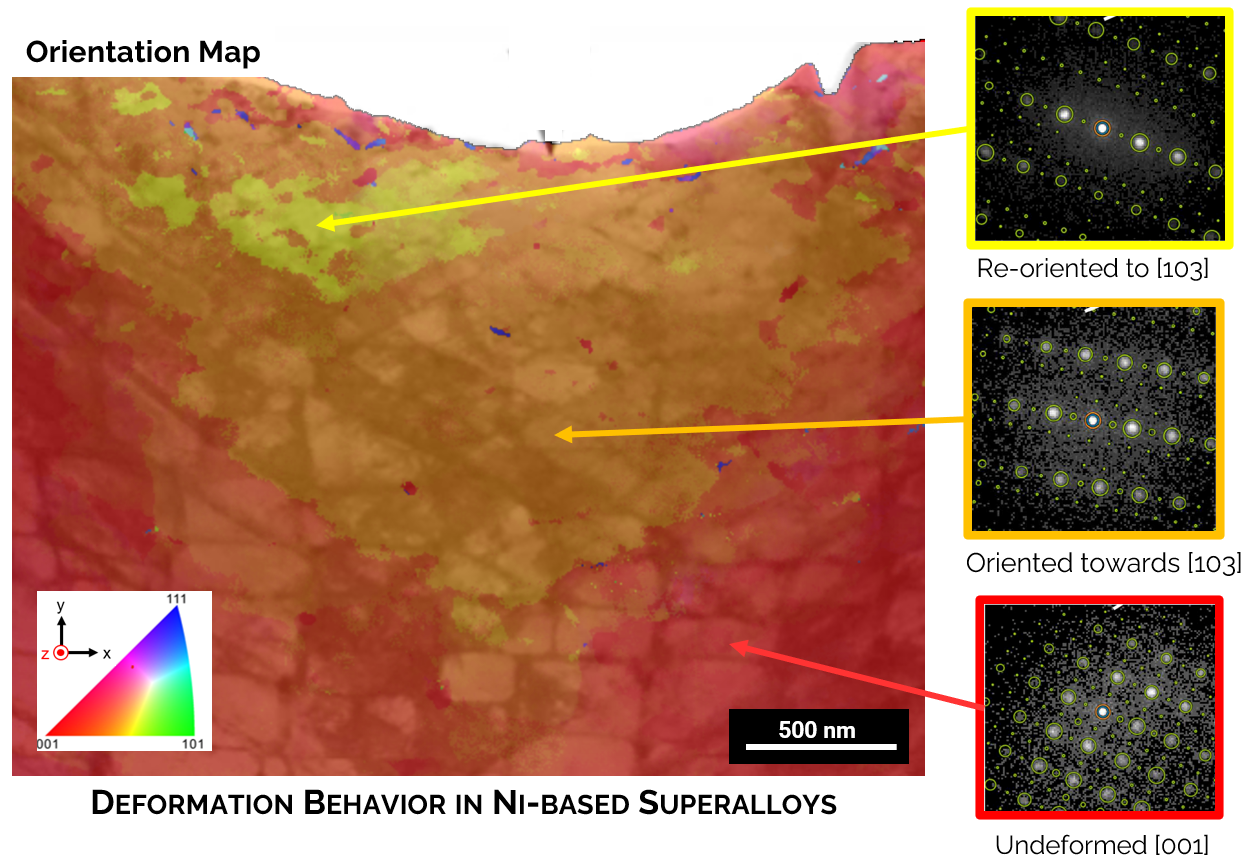

- Precession-assisted diffraction imaging for accurate orientation mapping

- Automated optical alignments and fast, hybrid-pixel, direct detector for high yield, high-quality data

- On-the-fly processing of diffraction data for interactive 4D-STEM analysis with meaningful results

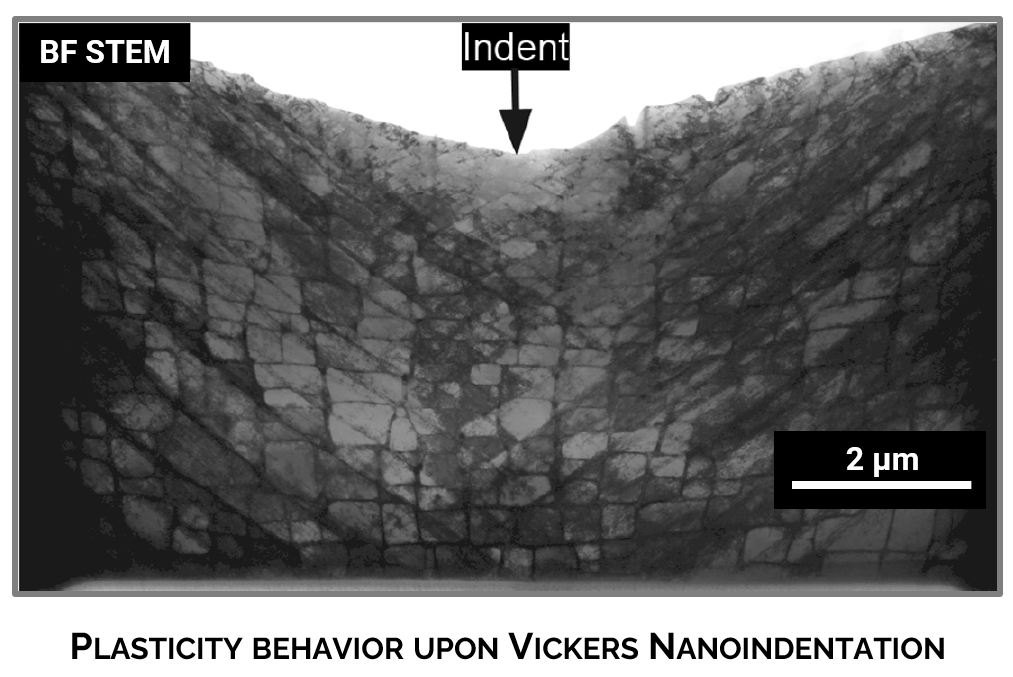

- Ideal for structural studies of deformation and grain boundary behavior over large regions of interest.