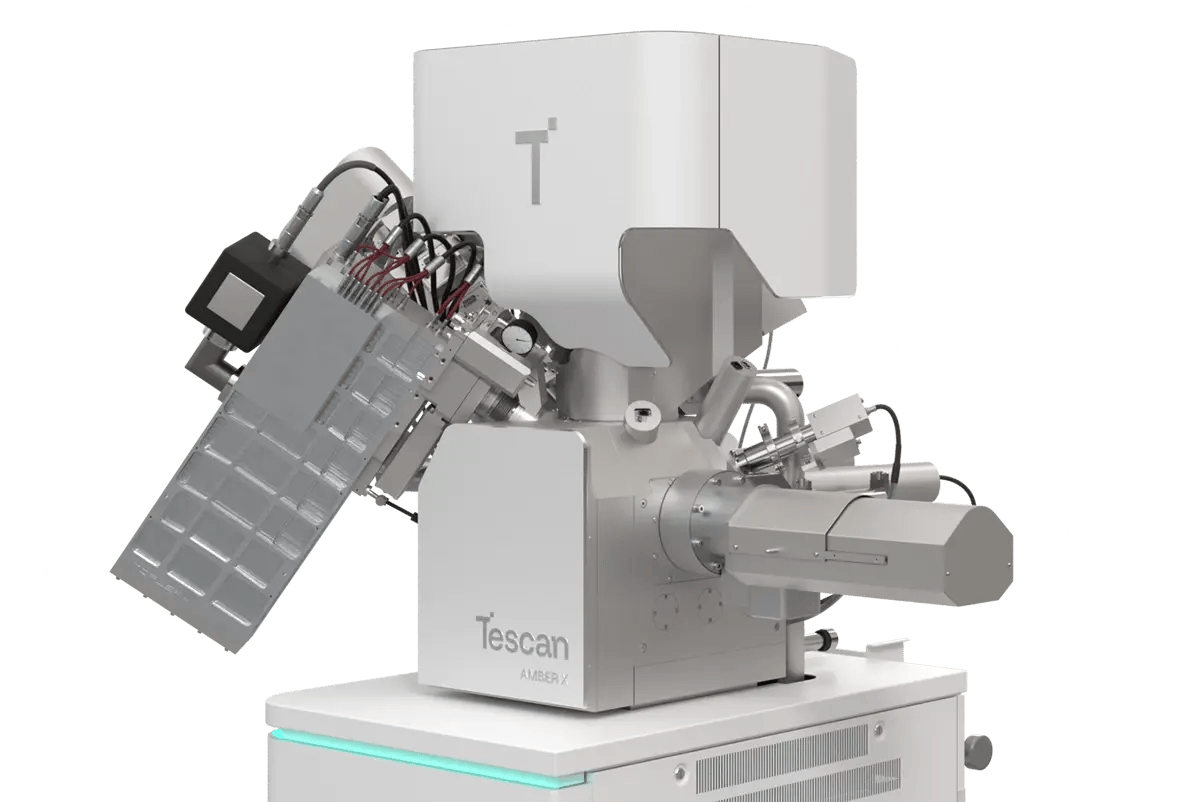

Use an integrated plasma FIB workflow with precise endpoint control and in situ nanoprobing to achieve clean, planar delayering of sub-20 nm semiconductor nodes. This approach preserves structural integrity and prepares samples for immediate electrical and structural analysis.

- Uniform layer removal: Prevents damage to delicate metals and dielectrics

- Real-time endpoint monitoring: Ensures accurate layer targeting

- In situ probing: Enables direct electrical testing without sample transfer