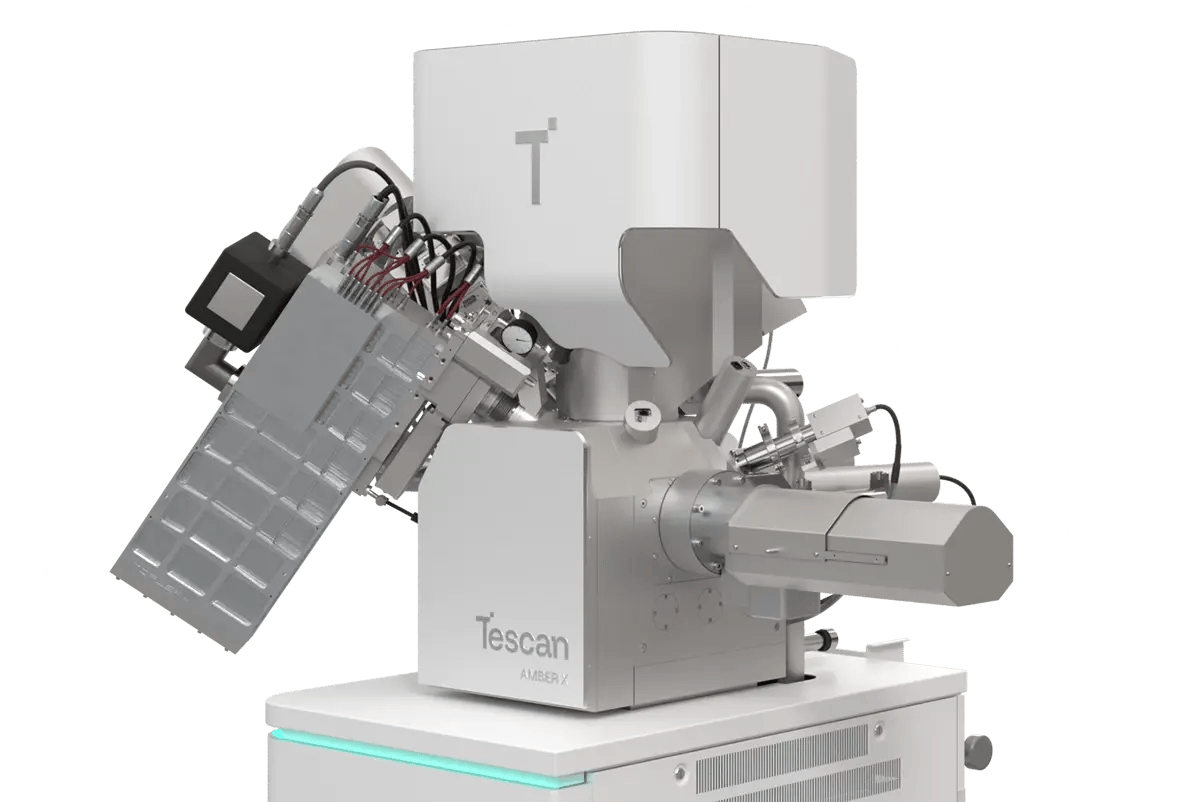

Tescan AMBER X 2 Plasma FIB-SEM

Tescan AMBER X 2 Plasma FIB-SEM combines a high-throughput Xe+ plasma FIB with a field-free UHR SEM column, enabling large-area delayering and ultra-high-resolution imaging in a single workflow.

Designed for advanced semiconductor failure analysis, it delivers precise control, uniform planarity, and direct integration with in-situ nanoprobing.

You can delayer complex logic and memory devices, expose transistor layers with real-time endpoint detection, and prepare contamination-free surfaces optimized for electrical probing and TEM readiness.

- Xe+ plasma FIB: high-throughput milling for large-area delayering of sub-20 nm nodes

- Field-free UHR SEM: ultra-high-resolution imaging without magnetic interference

- Mistral Plasma FIB: low keV gentle layer removal during delayering

- Real-time SE signal end pointing: accurate transistor exposure without over-milling

- Nanoflat etch: dielectric surface smoothing below 5 nm RMS roughness

- Nanoflat gas chemistry: selective copper removal with oxidation-free surfaces

- In-situ nanoprobing compatibility: seamless integration with Kleindiek PS8 for electrical analysis