Tescan AMBER

Tescan AMBER integrates high-resolution SEM imaging with focused ion beam milling for accurate trenching, lift-out, and thinning. Advanced automation supports multi-site, unattended workflows, while AURA Gentle Ion Beam polishing minimizes surface damage and preserves lamella integrity.

Advanced automation supports multi-site preparation, making it ideal for unattended TEM workflows.

-

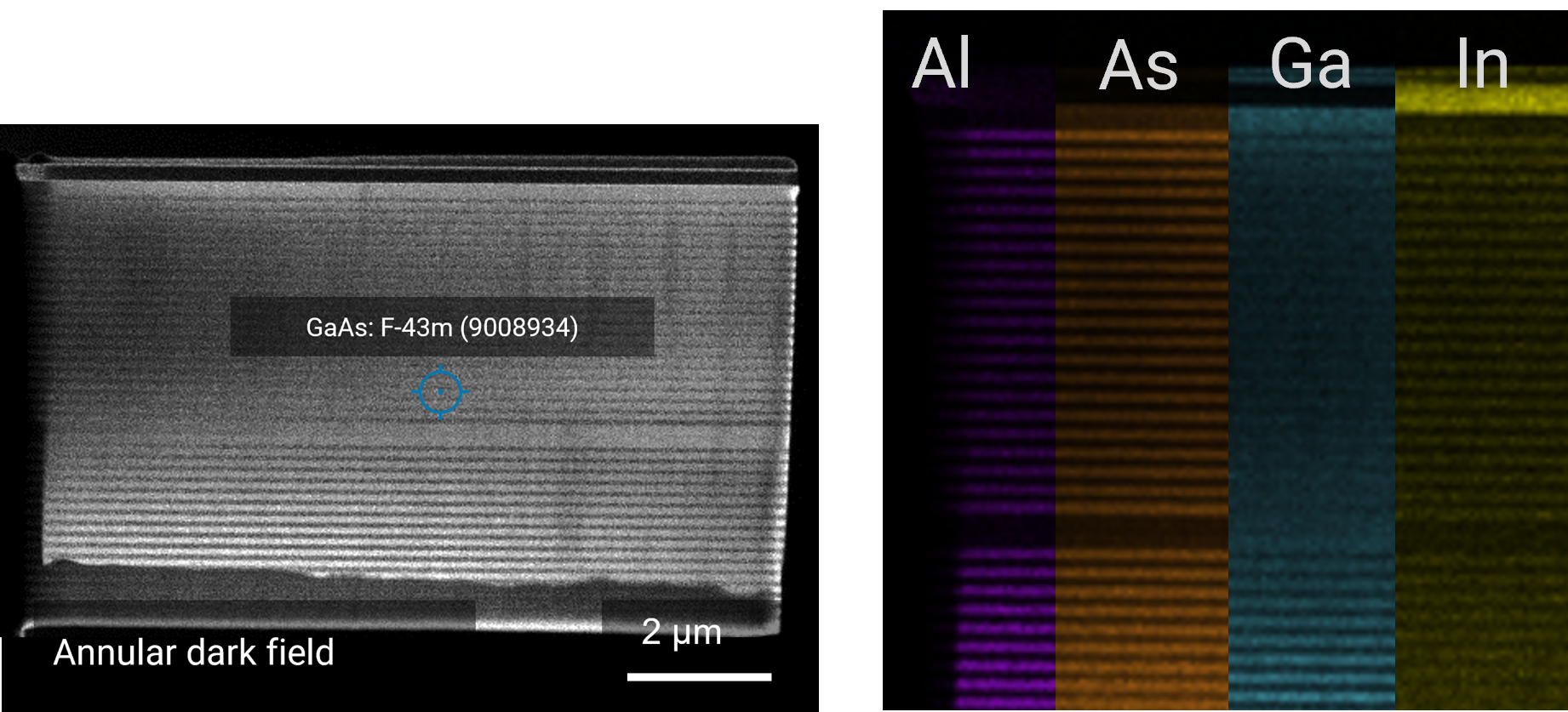

Gallium FIB milling: high-precision trenching and thinning

-

Field-free UHR SEM imaging: ensures accurate targeting and endpointing

-

In-situ lift-out capabilities: reduce contamination and handling risks

-

Multi-site automation: enables batch preparation across multiple regions

-

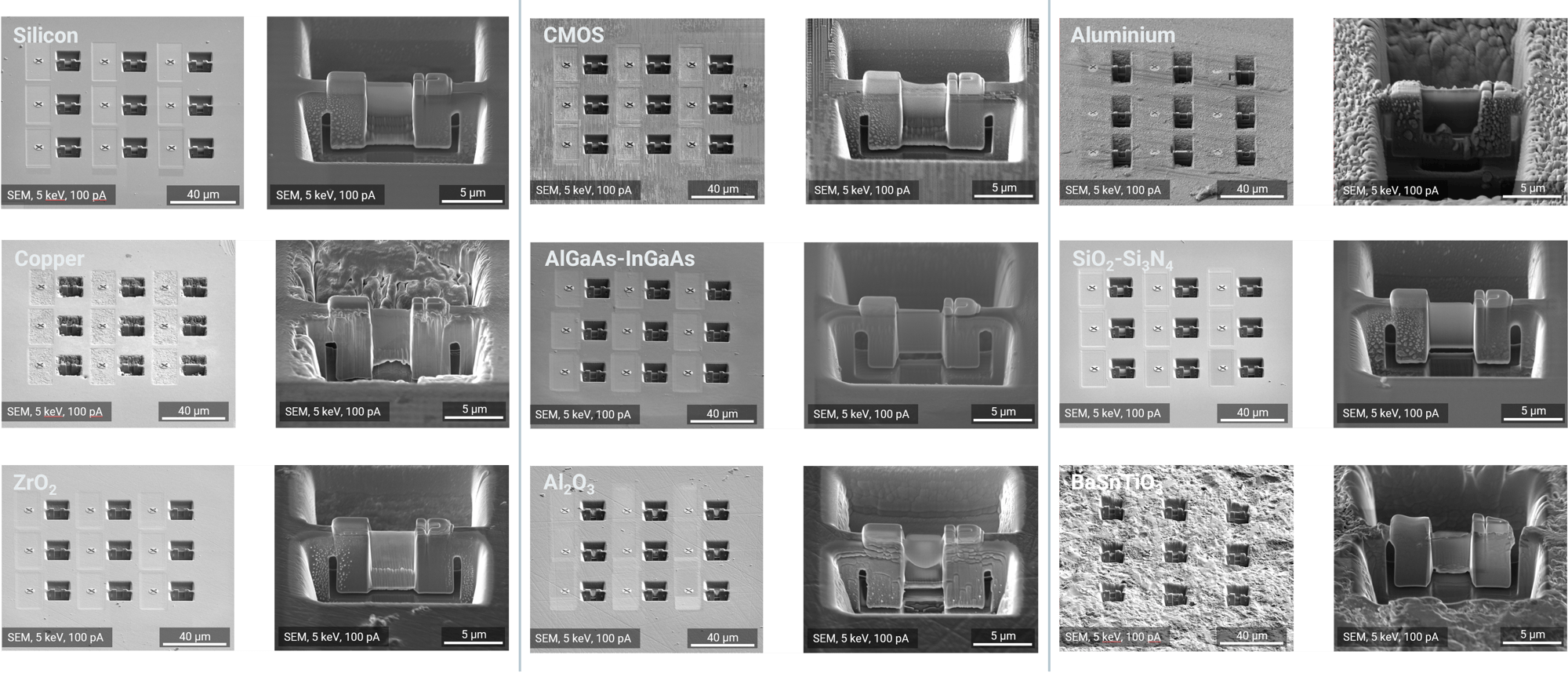

Reliable lamella stability: consistent preparation across soft and hard materials

-

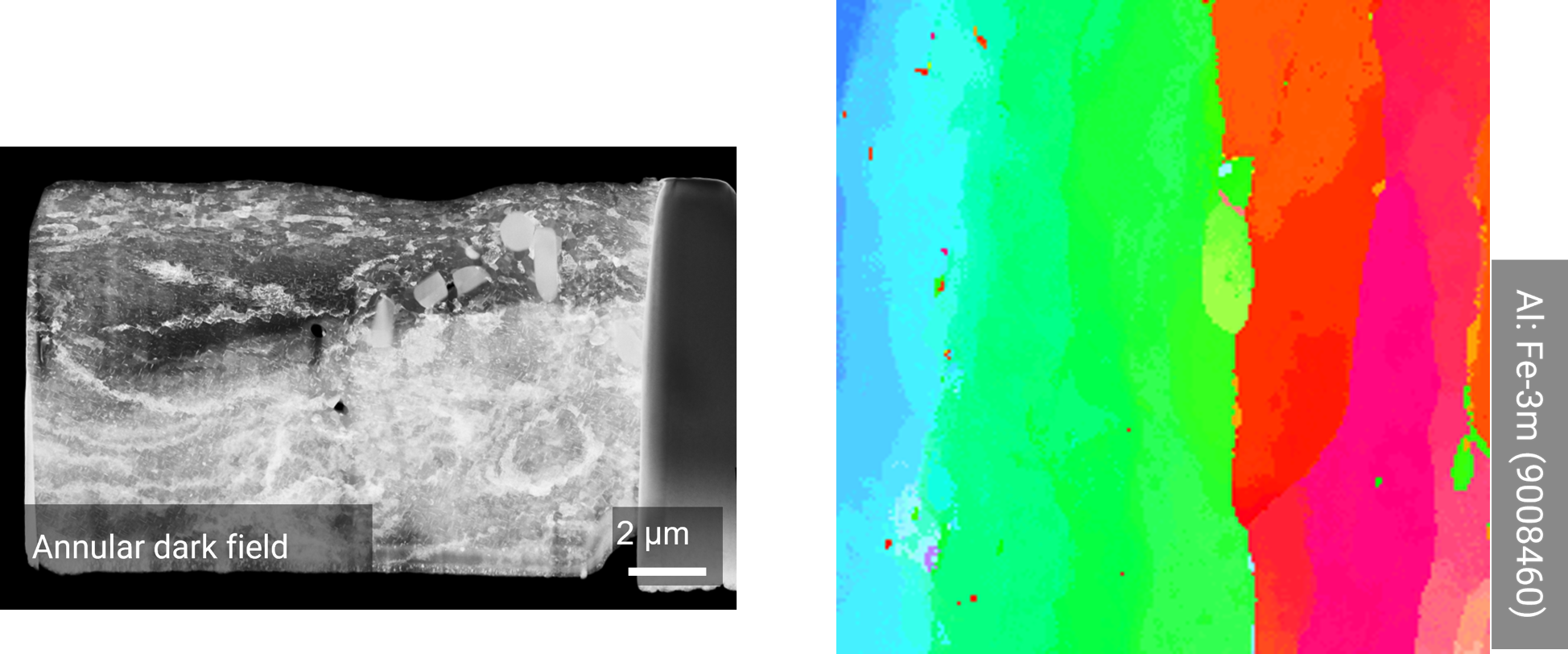

AURA Gentle Ion Beam polishing: reduces surface damage and preserves fine structure

%20lamella%20prepared%20in%20trench%20after%20undercut-1.png?width=1070&height=1004&name=Large%20(55%20um%20x%2030%20um)%20lamella%20prepared%20in%20trench%20after%20undercut-1.png)