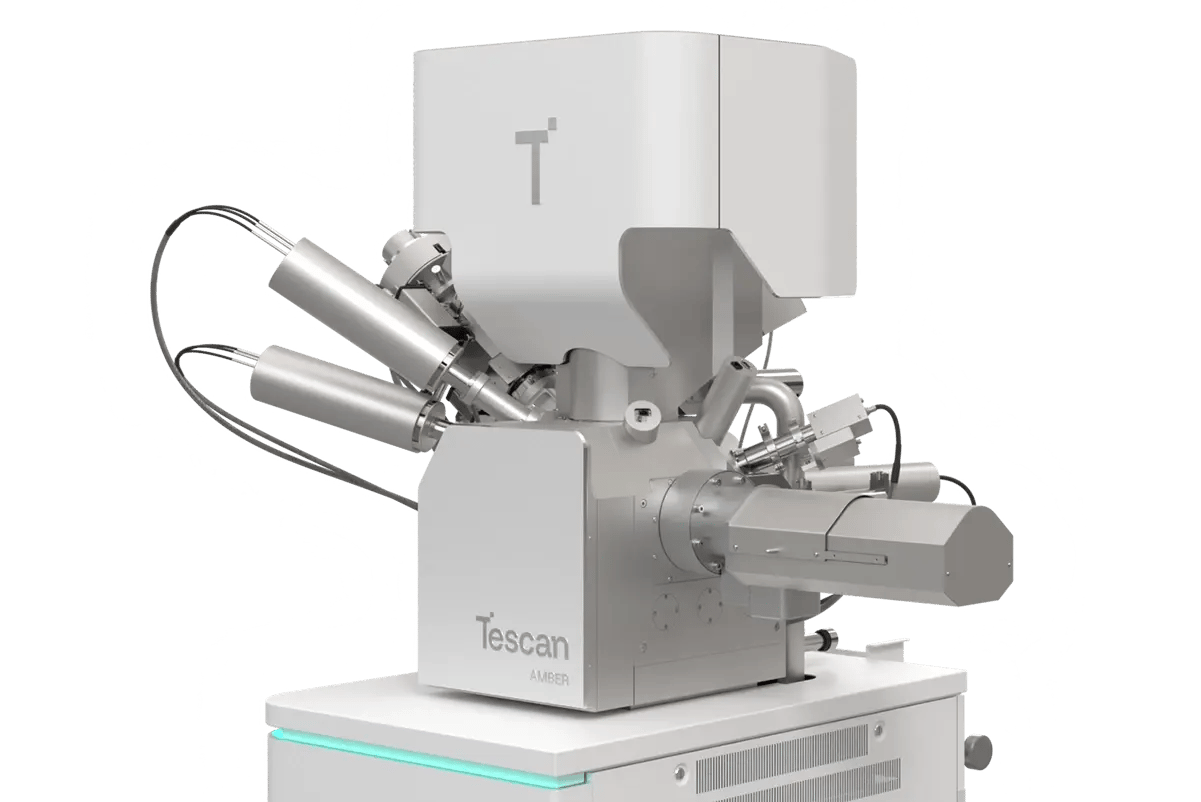

Tescan AMBER

Tescan AMBER is a versatile nanoanalytical FIB-SEM workstation designed for high-precision milling and ultra-high-resolution imaging. In this workflow, Tescan AMBER provided the stability and control needed to prepare consistent TEM lamellae from titanium alloy samples.

- Gallium FIB: High-precision milling for site-specific TEM lamella preparation

- Ultra-high-resolution SEM imaging: Accurate navigation and inspection during preparation

- Stable performance: Reliable sample preparation across complex material structures

- Integrated automation: Supports reproducible workflows for TEM analysis

.webp?width=1244&height=354&name=Nov%C3%BD%20projekt%20(11).webp)

.webp?width=813&height=215&name=Nov%C3%BD%20projekt%20(10).webp)

.webp?width=601&height=205&name=chart%20(1).webp)

%20lamella%20prepared%20in%20trench%20after%20undercut-1.png?width=1070&height=1004&name=Large%20(55%20um%20x%2030%20um)%20lamella%20prepared%20in%20trench%20after%20undercut-1.png)