Tescan UniTOM XL

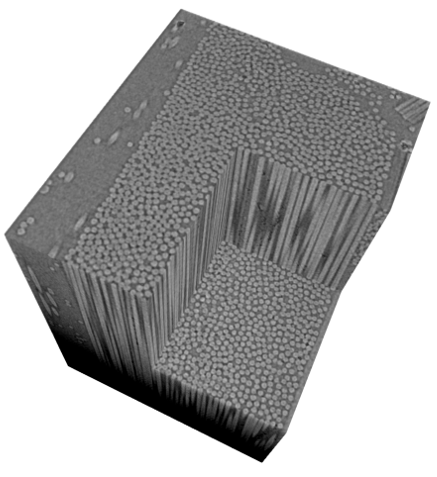

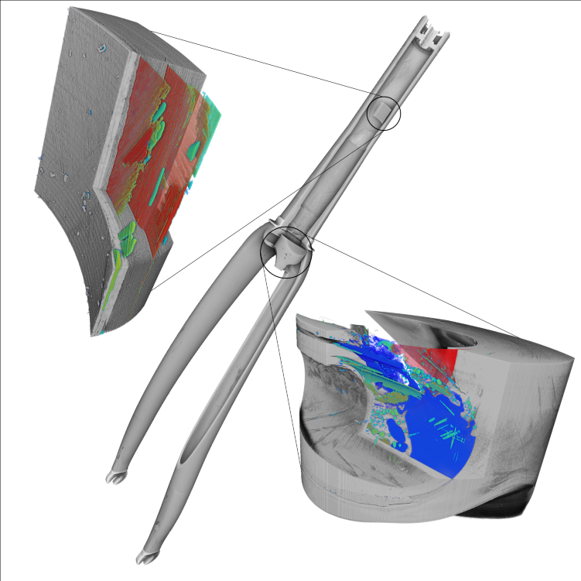

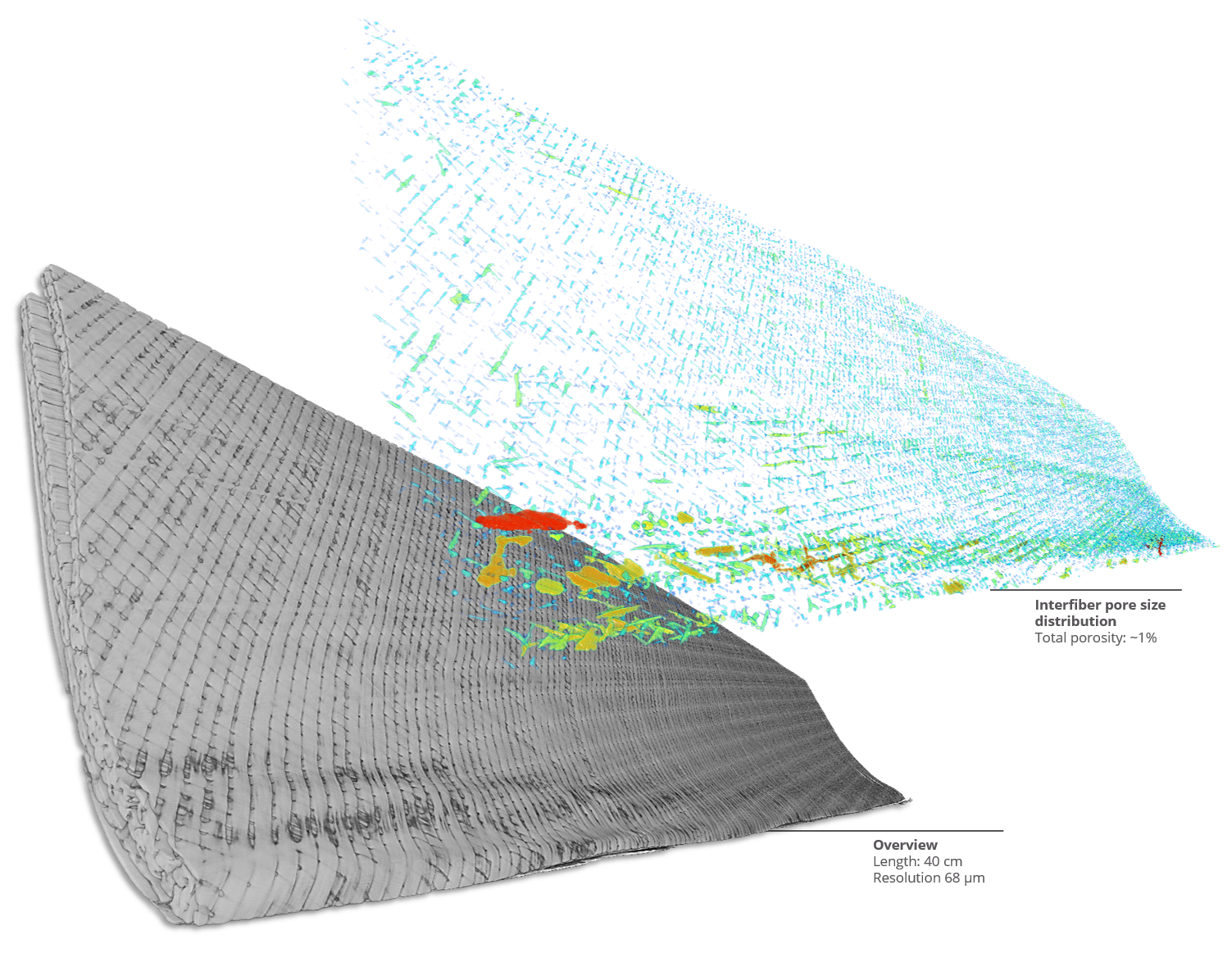

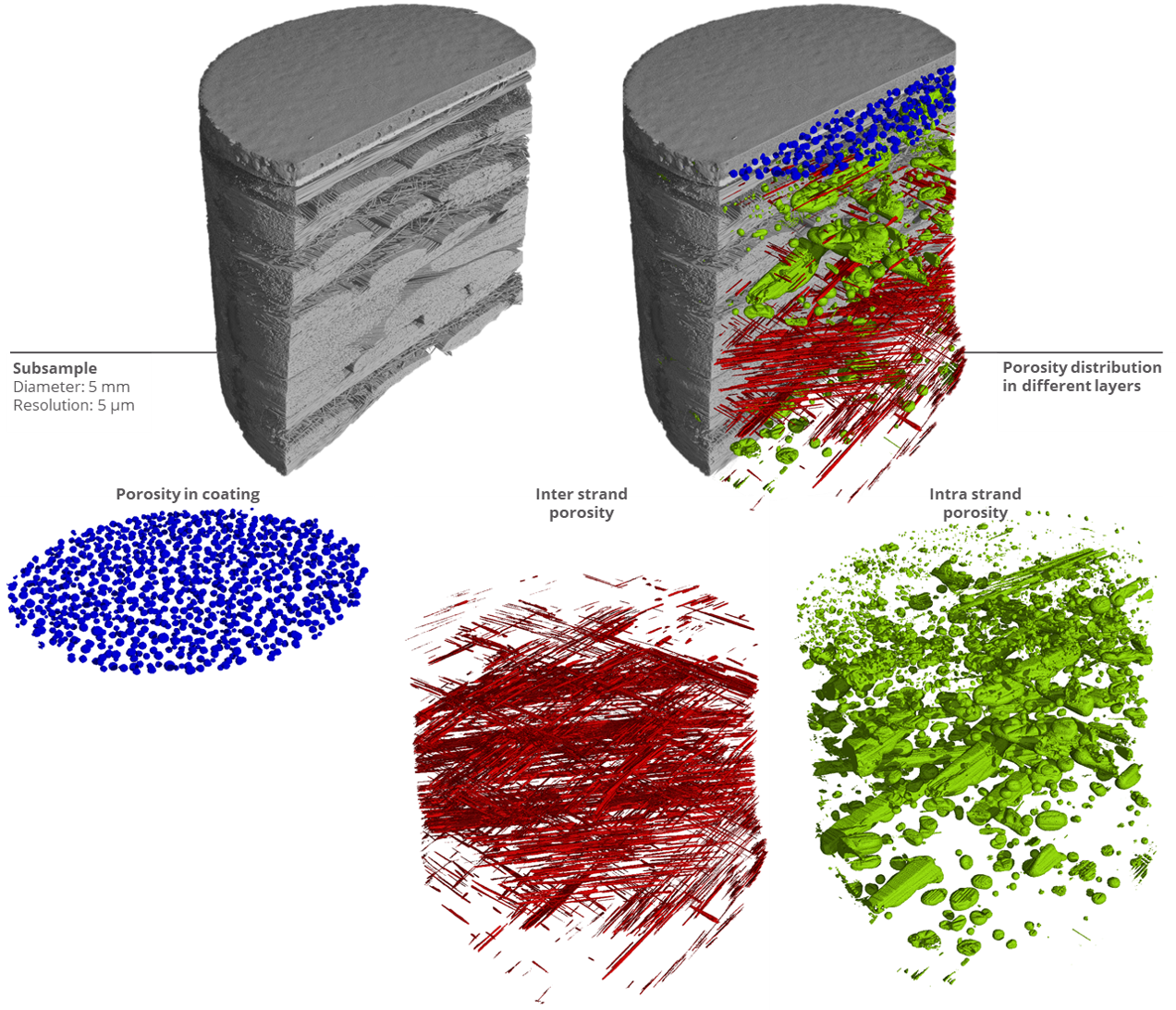

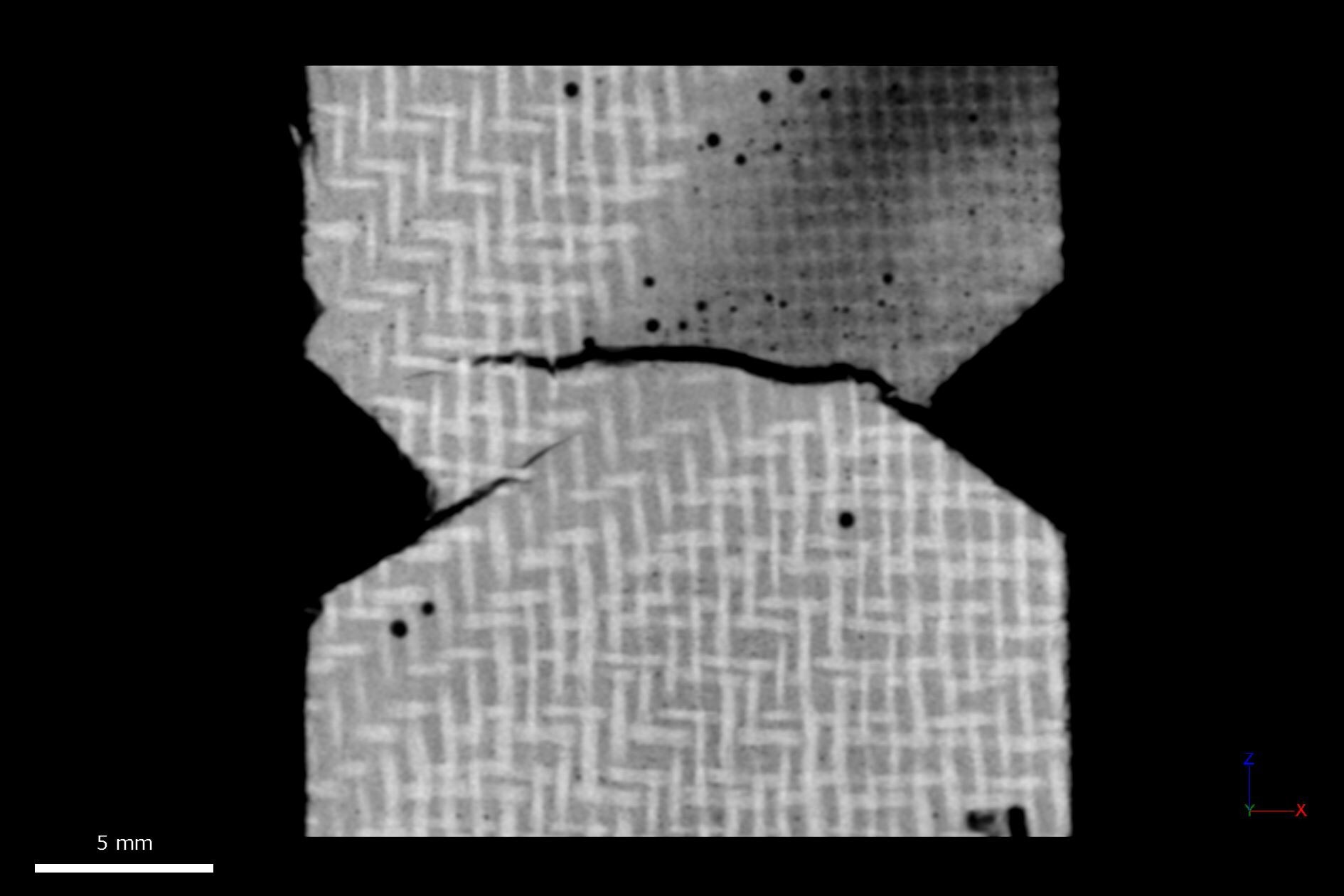

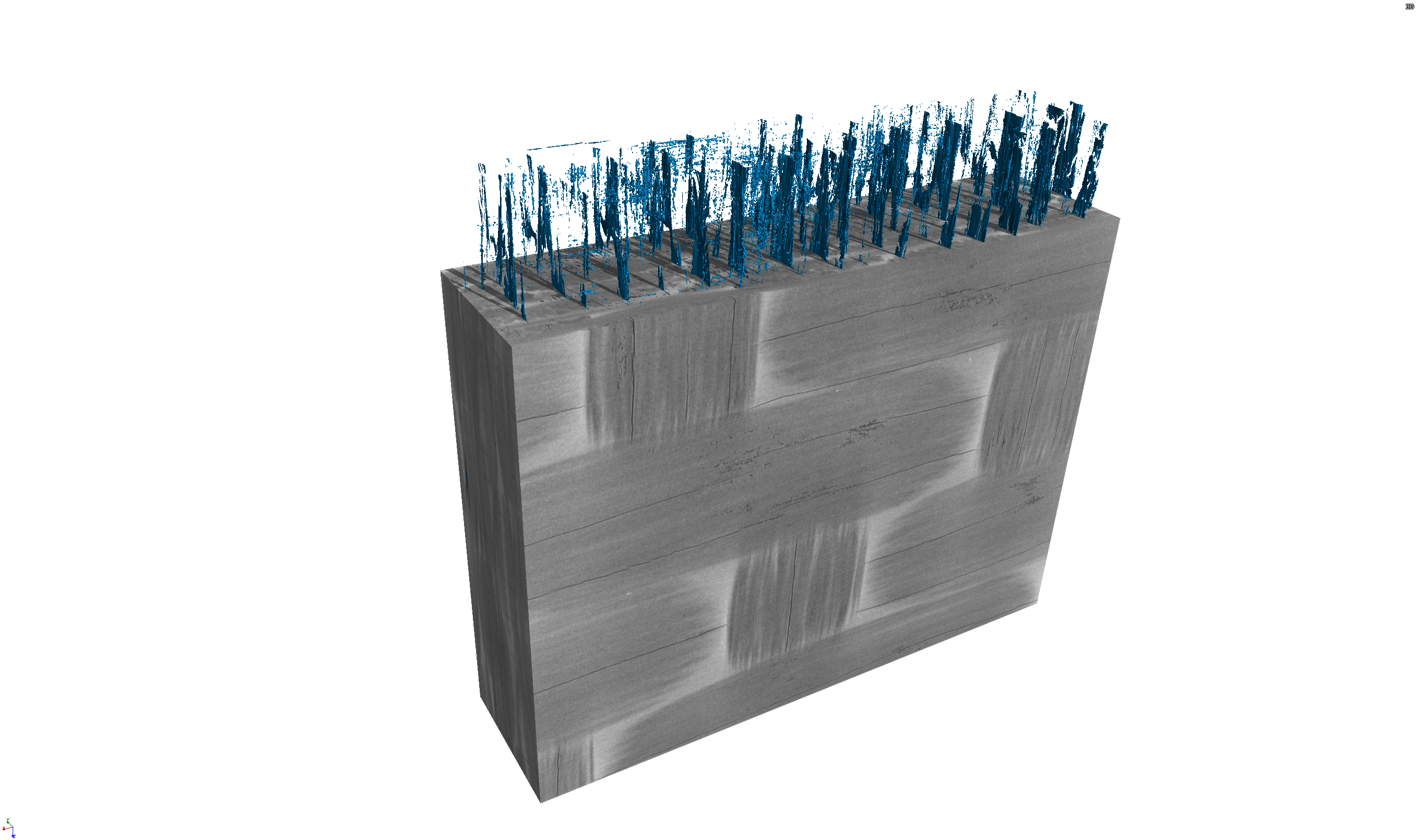

Tescan UniTOM XL is a high-resolution, multiscale X-ray micro-CT system designed for non-destructive 3D imaging of advanced composite materials. It enables full-volume analysis of wind blade sections, fiber-reinforced components, and layered structures. Users can capture both macro scale geometry and sub-micron detail without altering the sample.

- Non-destructive volumetric imaging: captures internal structure without cutting or coating

- Multi-resolution CT acquisition: resolves features from full assemblies to individual fibers

- Dynamic micro-CT mode: supports in situ mechanical testing and real-time damage monitoring

- Stable imaging stage: minimizes motion artifacts for consistent, high-fidelity datasets

- Integrated software platform: provides 3D reconstruction, segmentation, and quantitative analysis

%20of%20AM%20metal%20powder%2c%20mapping%20of%20particles%20with%20voids%20(red)%20and%20impurities%20(yellow)-6.png?width=1438&height=1261&name=03_High%20resolution%20scan%20(1%20%CE%BCm%20voxel%20size)%20of%20AM%20metal%20powder%2c%20mapping%20of%20particles%20with%20voids%20(red)%20and%20impurities%20(yellow)-6.png)