Tescan UniTOM XL and CoreTOM

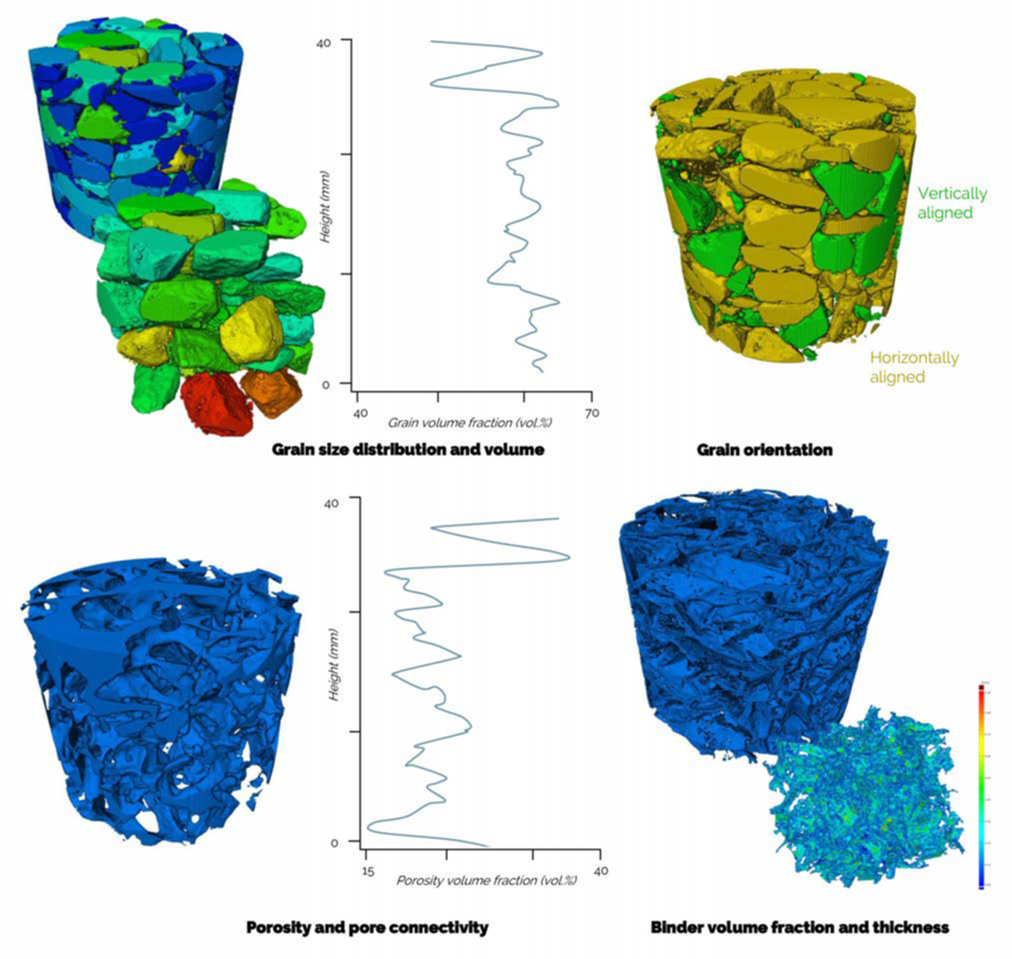

Tescan UniTOM XL and CoreTOM are high-resolution, multiscale X-ray micro-CT systems designed for non-destructive 3D imaging of large geological and construction materials. They enable full-volume analysis of asphalt and concrete cores — from macroscopic structure to microstructural detail — with reproducible results and zero sample disruption.

- Non-destructive volumetric imaging: preserves geometry and internal structure

- Flexible voxel resolution: captures features from millimeter to sub-micron scale

- Dynamic micro-CT mode: supports in situ compression testing and time-resolved imaging

- High-stability rotary stage: ensures artifact-free acquisition across full cores

- Integrated software platform: delivers advanced 3D reconstruction and quantitative analysis

%20of%20AM%20metal%20powder%2c%20mapping%20of%20particles%20with%20voids%20(red)%20and%20impurities%20(yellow)-4.png?width=1438&height=1261&name=03_High%20resolution%20scan%20(1%20%CE%BCm%20voxel%20size)%20of%20AM%20metal%20powder%2c%20mapping%20of%20particles%20with%20voids%20(red)%20and%20impurities%20(yellow)-4.png)