Tescan UniTOM XL

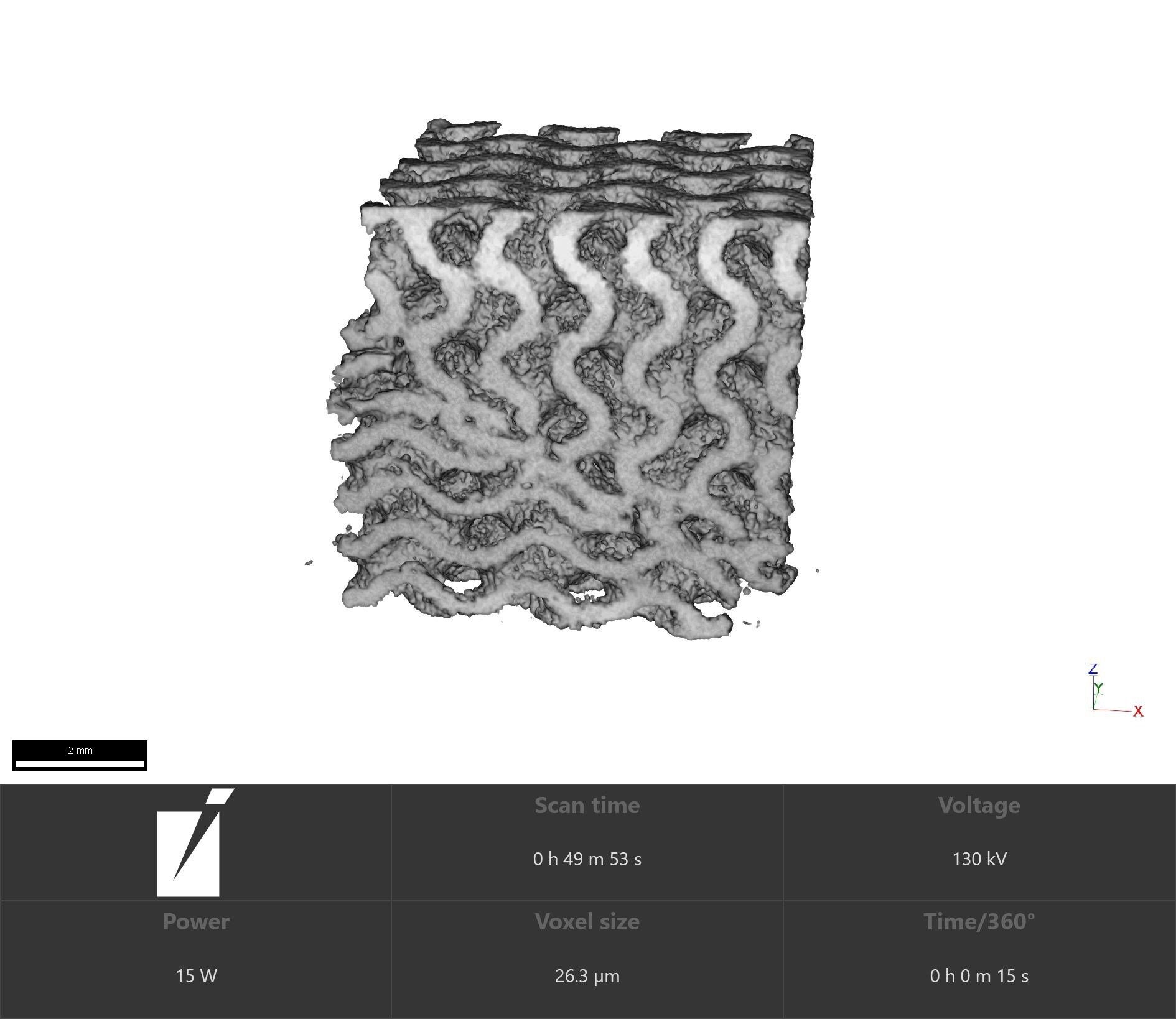

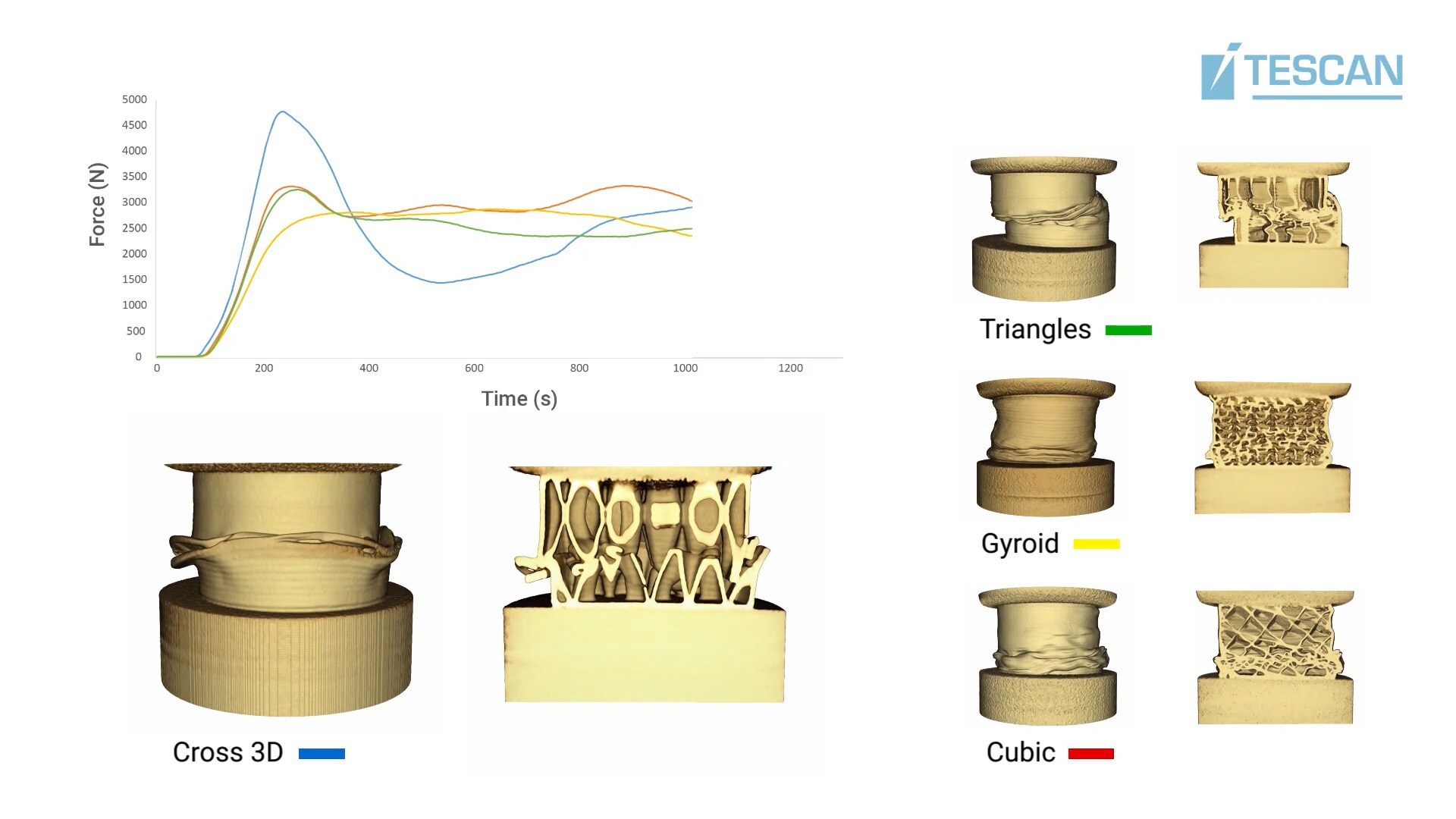

Tescan UniTOM XL integrates in-situ mechanical testing with high-resolution micro-CT to capture internal structural changes as they unfold inside additive manufactured parts.

Real-time imaging reveals how cracks initiate, pores expand, and material deforms under load. All of this is achieved without interrupting the test or altering the sample.

- In-situ mechanical integration: enables synchronized compression or tensile testing during scanning

- Dynamic micro-CT: tracks structural evolution with temporal resolution in as fast as 15 seconds

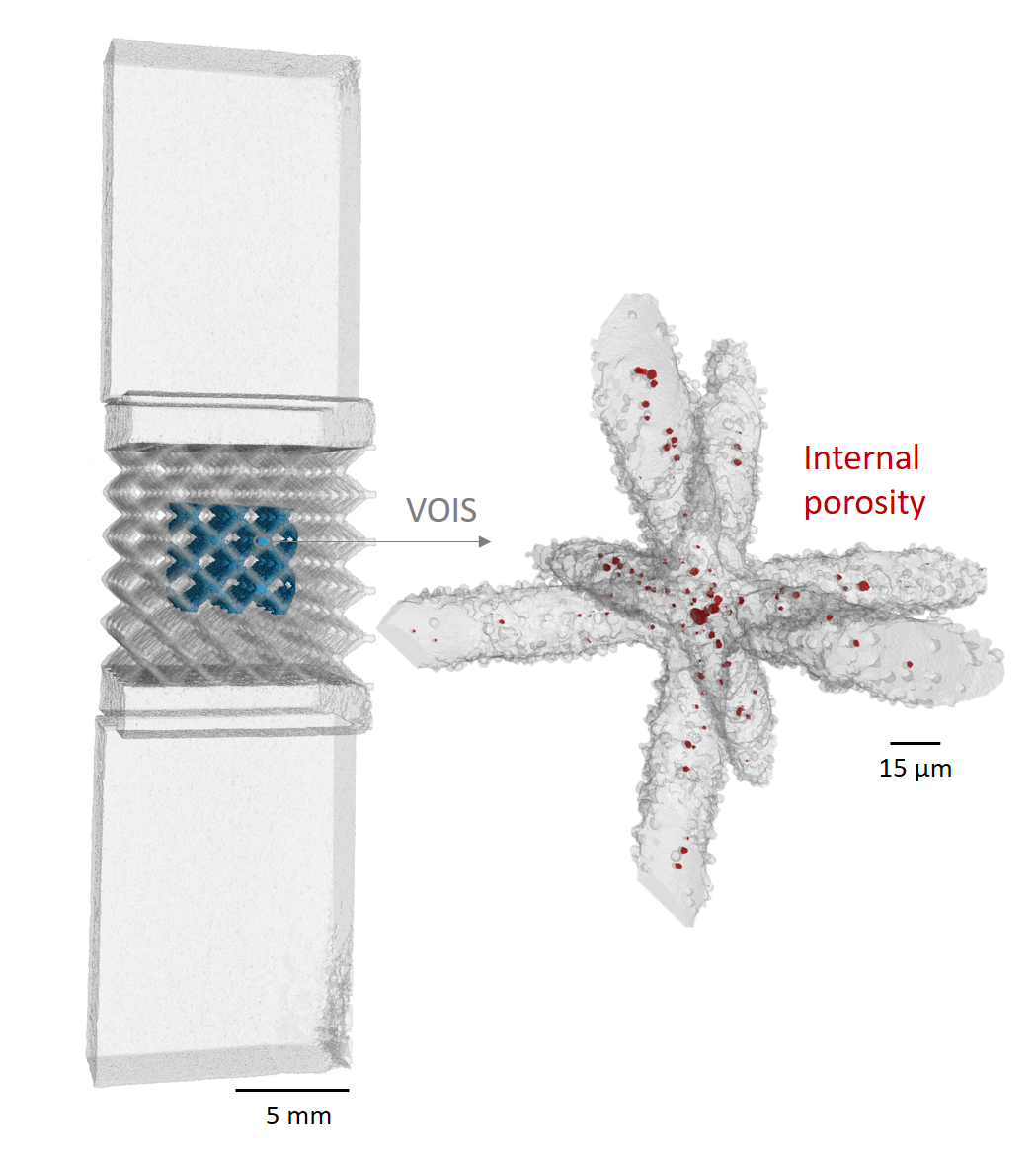

- Non-destructive acquisition: preserves geometry and microstructure for continuous observation

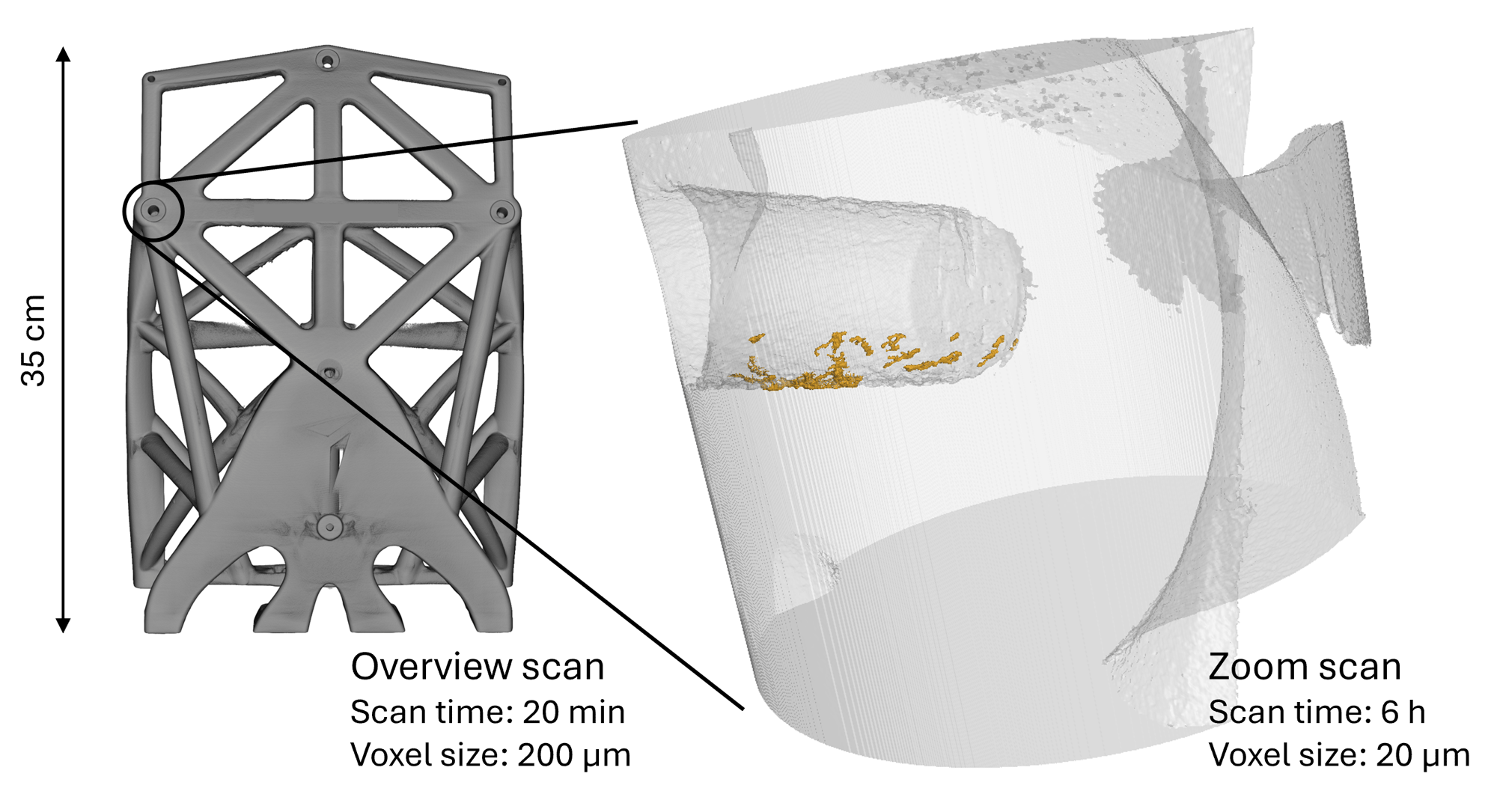

- Volume of Interest (VOI) scanning: combines overview imaging with high-resolution targeting

- Multi-scale resolution options: support full-part context and localized defect analysis

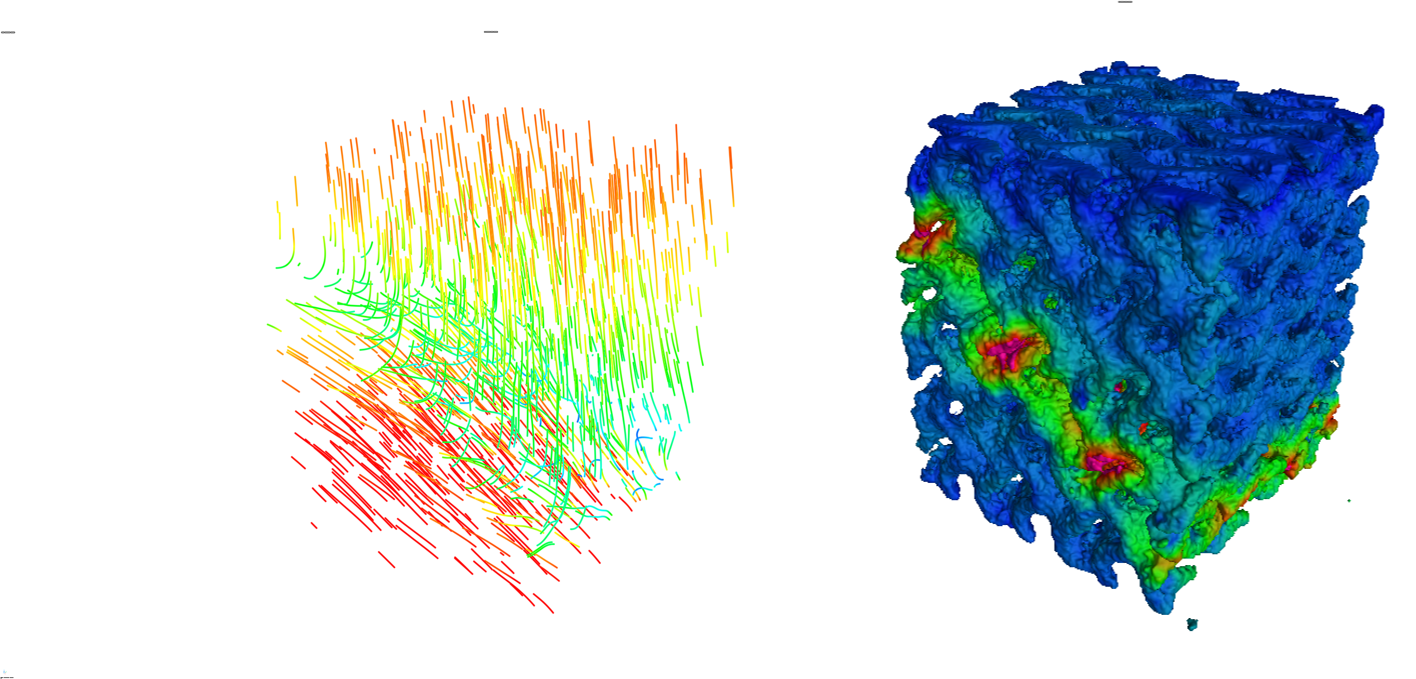

- Quantitative 3D analysis tools: measure strain, displacement, and internal failure pathways over time

%20of%20AM%20metal%20powder%2c%20mapping%20of%20particles%20with%20voids%20(red)%20and%20impurities%20(yellow).png?width=1438&height=1261&name=03_High%20resolution%20scan%20(1%20%CE%BCm%20voxel%20size)%20of%20AM%20metal%20powder%2c%20mapping%20of%20particles%20with%20voids%20(red)%20and%20impurities%20(yellow).png)