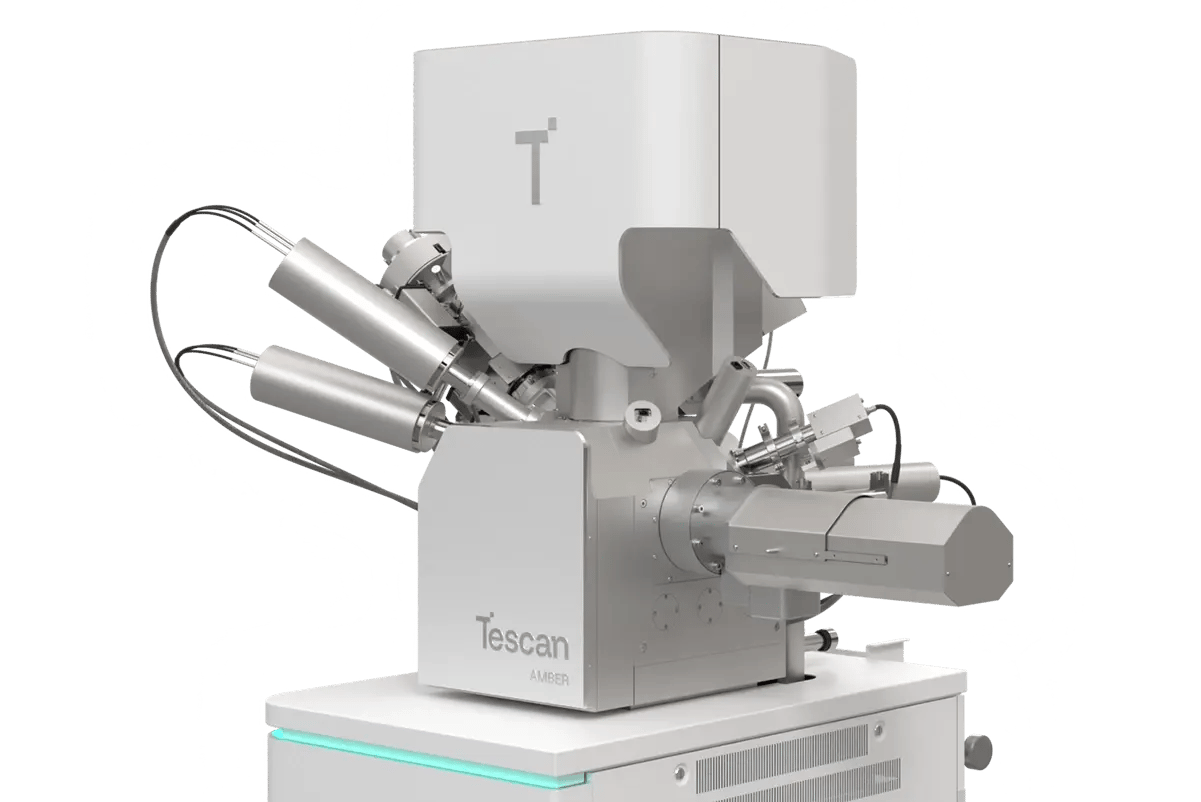

Tescan AMBER with Nanoprototyping Toolbox™

Tescan AMBER is a multi-functional FIB-SEM system designed for advanced nano-prototyping and in-situ device preparation.

It combines high-precision gallium ion beam milling, high-resolution SEM imaging, and integrated nanomanipulation — all within a fully controlled environment.

This enables complete workflows for ion implantation, nanowire lift-out, and electrical contact integration without transferring the sample between systems.

- Gallium FIB: enables precise ion implantation and FIB-induced deposition (FIBID)

- In-chamber nanomanipulator: supports accurate lift-out, placement, and alignment of 1D nanostructures

- Real-time SEM imaging: enables precise visual feedback and supports focused electron beam-induced deposition (FEBID)

- Direct gas injection: enables precise material deposition using electron or ion beams to modify or fabricate the sample

- Seamless integration: ideal for closed-loop prototyping and device-level testing at the nanoscale

.webp?width=606&height=456&name=chart%20(2).webp)

.png?width=2000&name=SOLARIS%20(2).png)