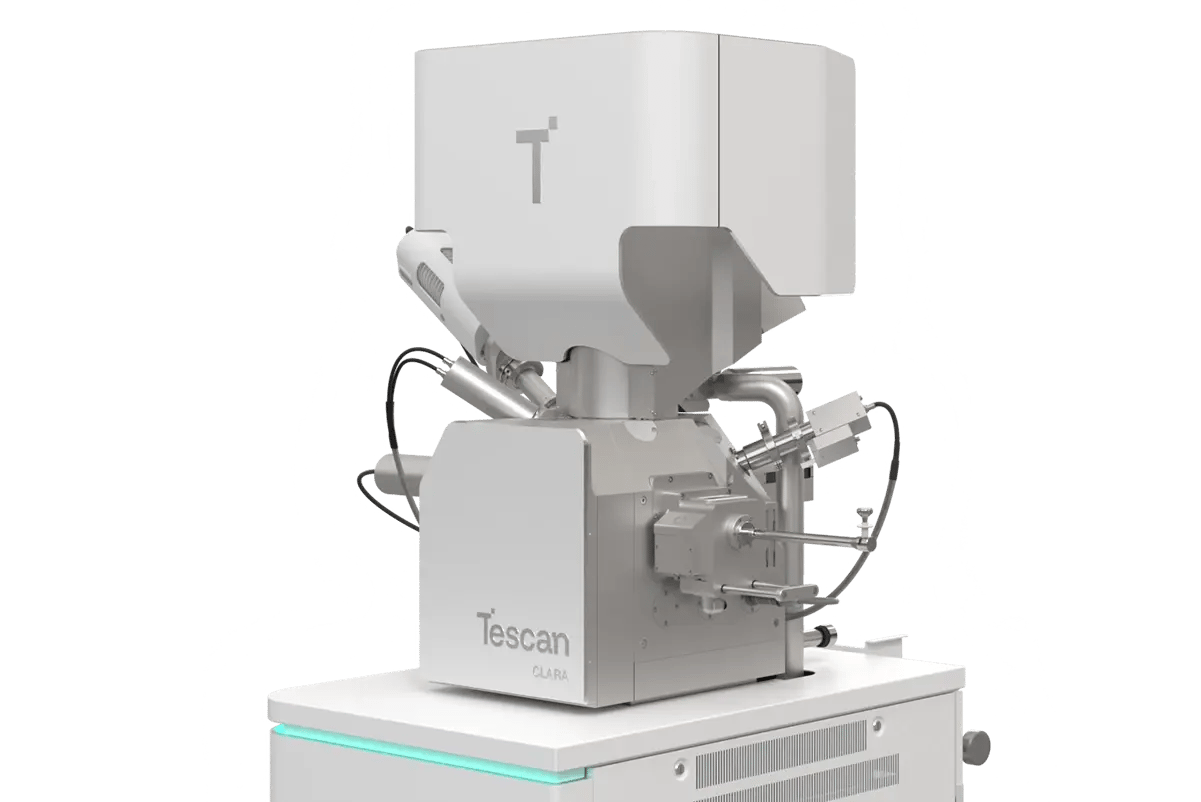

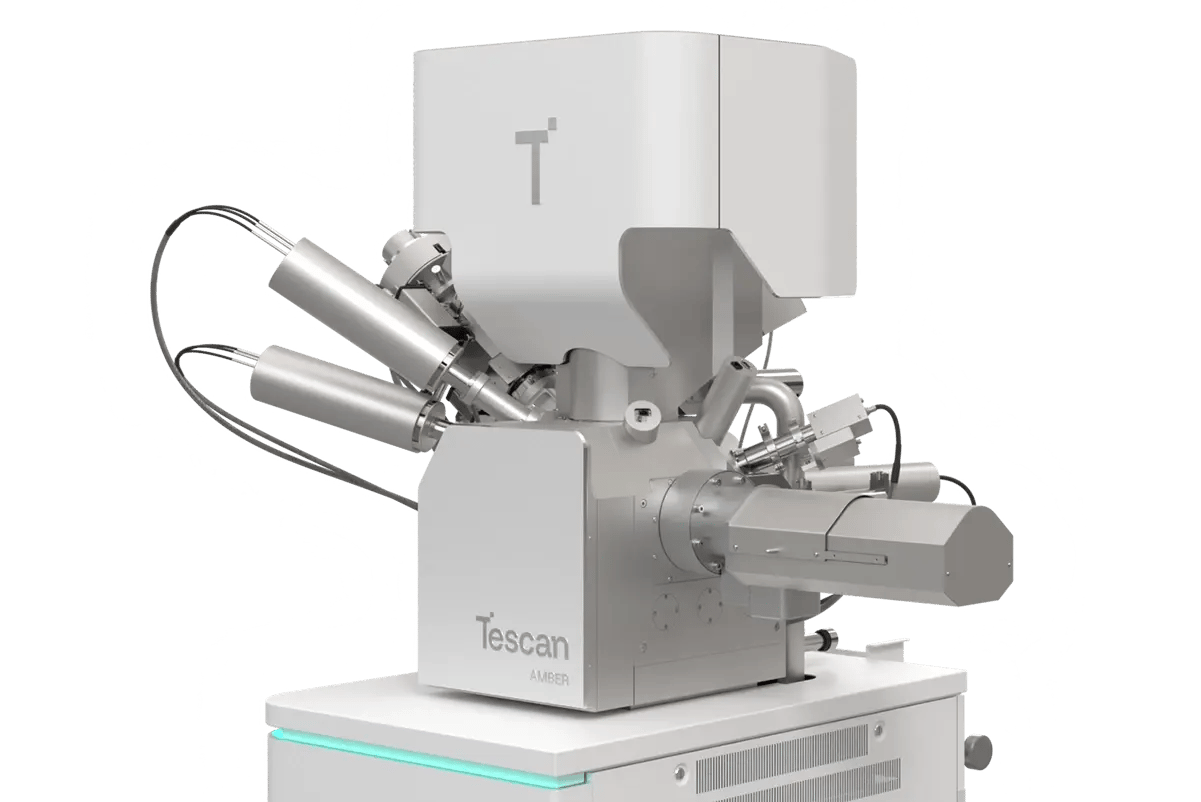

Tescan AMBER with FIB-SEM Expert PI™ API

Tescan AMBER combines high-precision gallium FIB milling with ultra-high-resolution SEM imaging in a versatile dual-beam platform.

As part of the nanoprototyping toolbox™, AMBER can be paired with the Tescan FIB-SEM Expert PI™ API (Application Programming Interface) to enable fully automated 3D nanofabrication workflows such as proximity-corrected Focused Electron Beam-Induced Deposition (FEBID).

You can control beam, stage, and gas on/off parameters directly from scripted recipes — ensuring reproducible, high-fidelity nanostructures without manual intervention.

- Gallium FIB: Sub‑micrometer milling and site‑specific cross‑sectioning

- Integrated SEM: Nanoscale imaging and process monitoring

- FIB-SEM Expert PI™ API: Direct scripting for automated beam and gas control

- Stream File protocol support: Execute complex, layer‑by‑layer deposition routines

- Gas injection compatibility: Deposit functional or structural materials in situ

![[Left] Result of the height calibration test. [Right] Result of the sigma calibration test. Both datasets are used to calibrate the growth rate parameters for the final 3D deposition process.](https://tescan.com/hs-fs/hubfs/Nov%C3%BD%20projekt%20(12).webp?width=1371&height=699&name=Nov%C3%BD%20projekt%20(12).webp)

.webp?width=720&height=339&name=chart%20(3).webp)

.webp?width=1366&height=671&name=Nov%C3%BD%20projekt%20(14).webp)