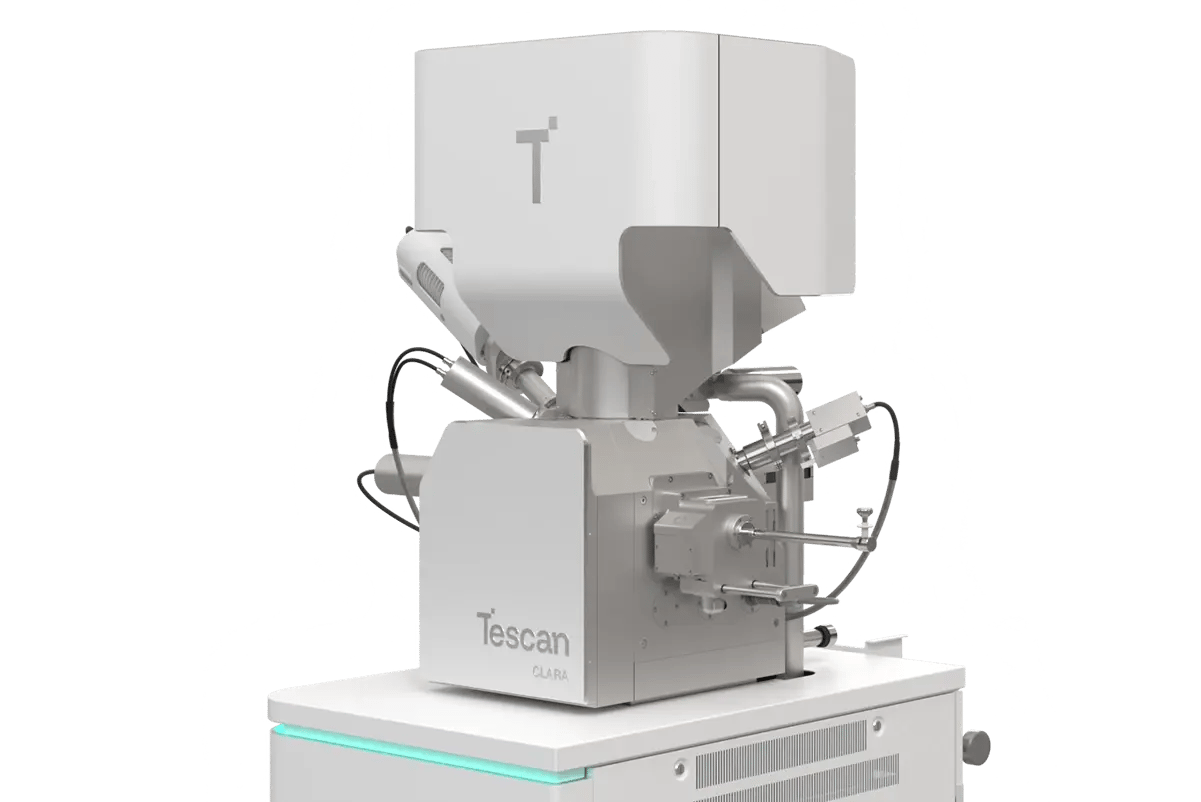

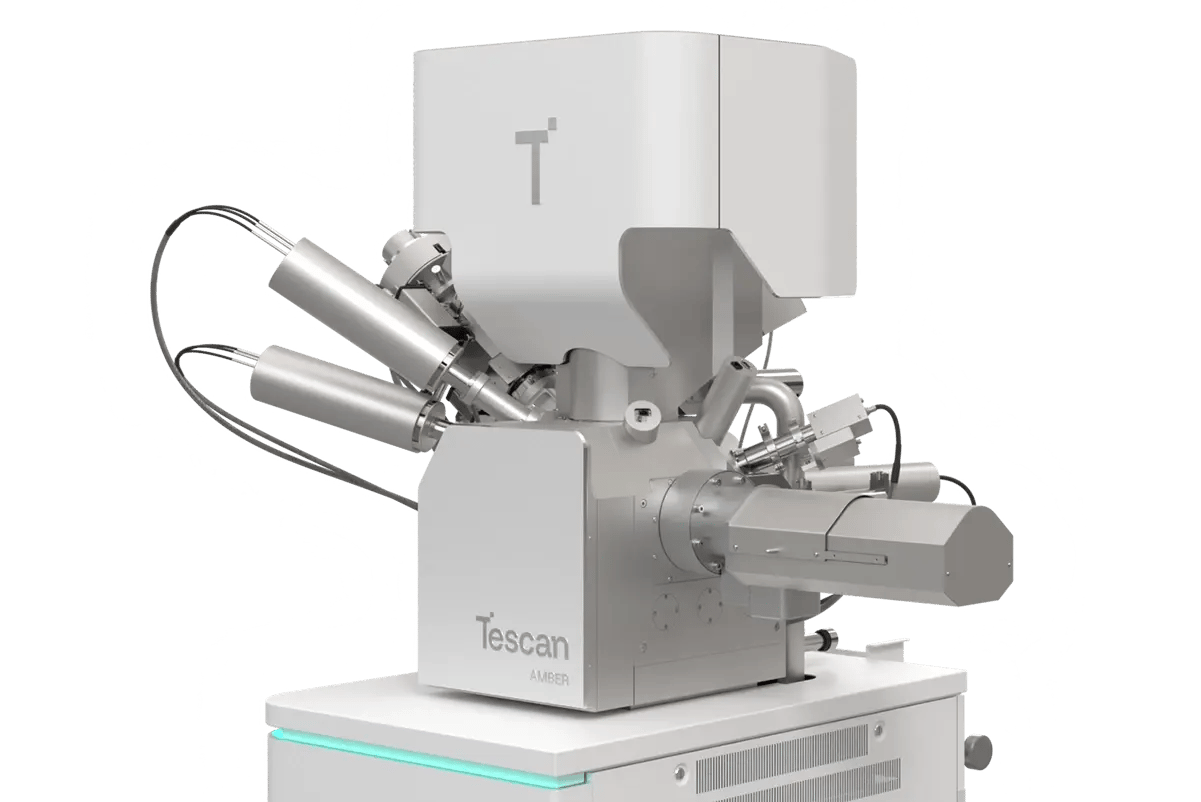

Tescan AMBER

Combining high‑precision milling, ultra‑high‑resolution imaging, and advanced automation for materials research and TEM sample preparation, Tescan AMBER enables researchers to perform site‑specific cross‑sectioning, 3D tomography, and correlative imaging workflows with exceptional accuracy and repeatability.

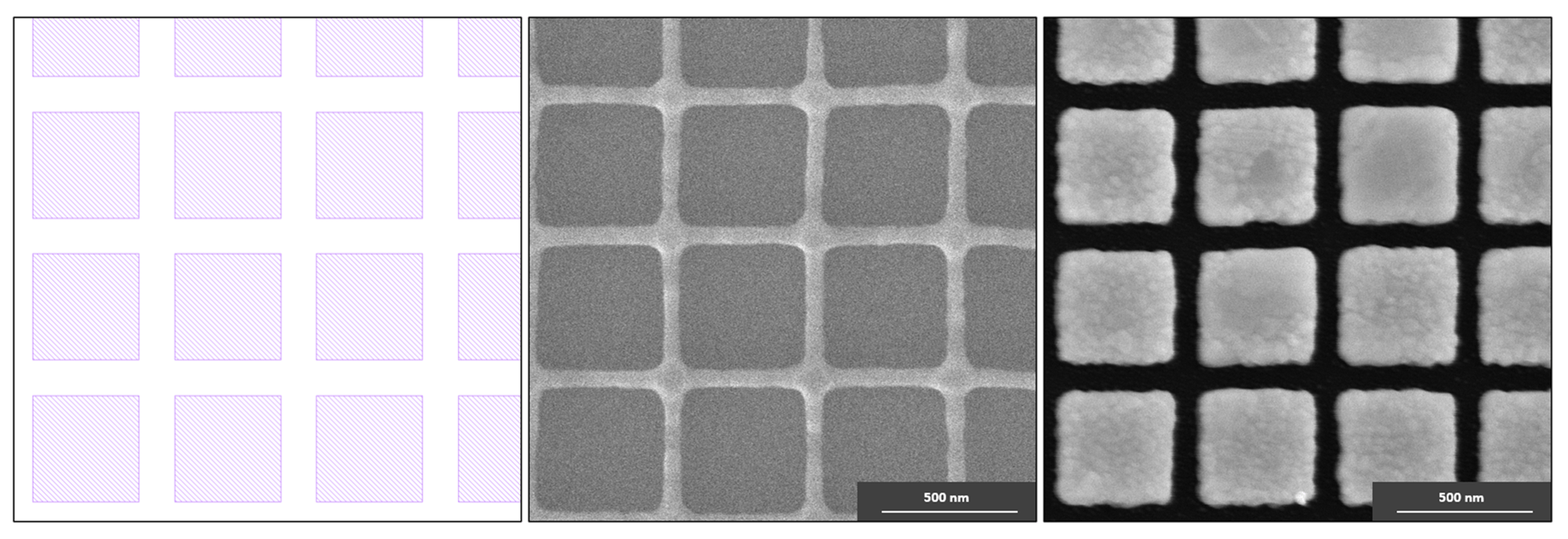

- Gallium FIB: High‑precision nanofabrication,cross‑sectioning and TEM prep

- Ultra‑high‑resolution SEM: Detailed imaging, structural analysis and electron beam lithography

- Nanoprototyping Toolbox™: Extends AMBER’s capabilities into advanced nanostructuring and prototyping workflows

- Advanced automation: Streamlined repetitive tasks and enable complex workflows or prototyping

- Gas Injection System (GIS): Enables in-situ deposition, etching, and enhanced milling strategies

- Application focus: Nanophotonics, plasmonics, surface modification, and novel material research including 2D materials and magnonics.

.webp?width=1024&height=1183&name=Figure%204%20(1).webp)

.webp?width=1024&height=1183&name=Figure%205%20(center).webp)