Combine open-source f3ast software with Tescan’s FIB-SEM Expert PI API to enable proximity-corrected, automated 3D nanoprinting workflows inside FIB-SEM systems. This integration delivers reproducible fabrication of complex nanostructures with precision and speed, accelerating the path from concept to device.

- Open-source workflow: f3ast software generates optimized recipes from 3D models

- API-based automation: Direct execution through the Tescan’s FIB-SEM Expert PI interface

- Growth and sigma calibration: Guarantees accurate height and geometry control

- Validated outcomes: Successful fabrication of spiral balls, helices, and other 3D nanoscale geometries

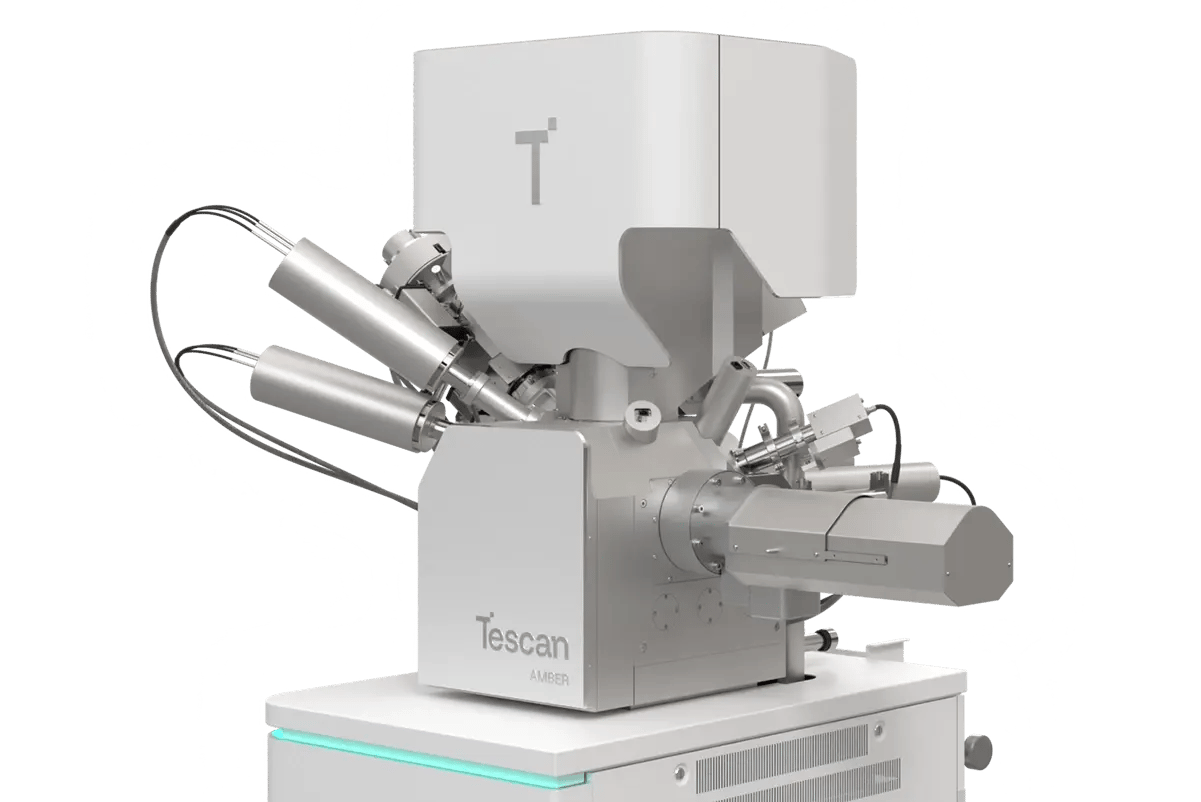

.webp?width=1700&height=1800&name=img5%20(4).webp)

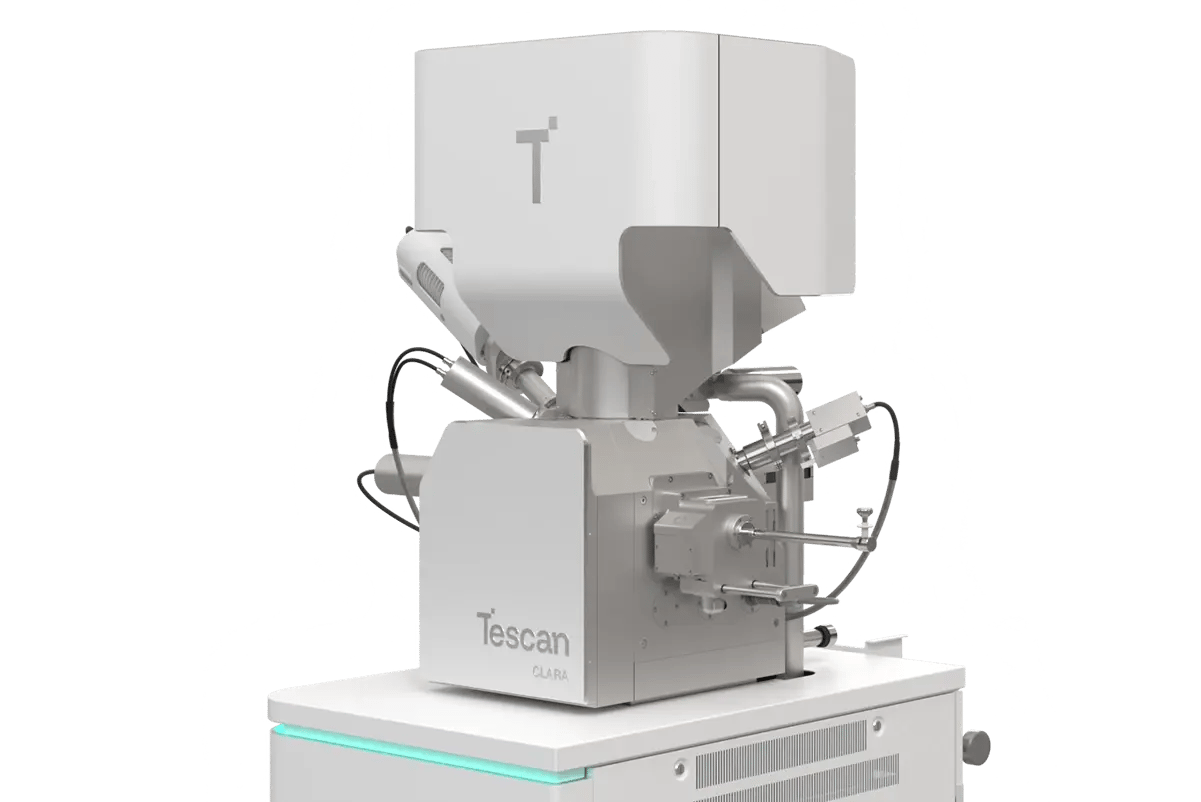

.webp?width=1700&height=1800&name=3-Nov-26-2025-11-36-43-3938-AM%20(1).webp)