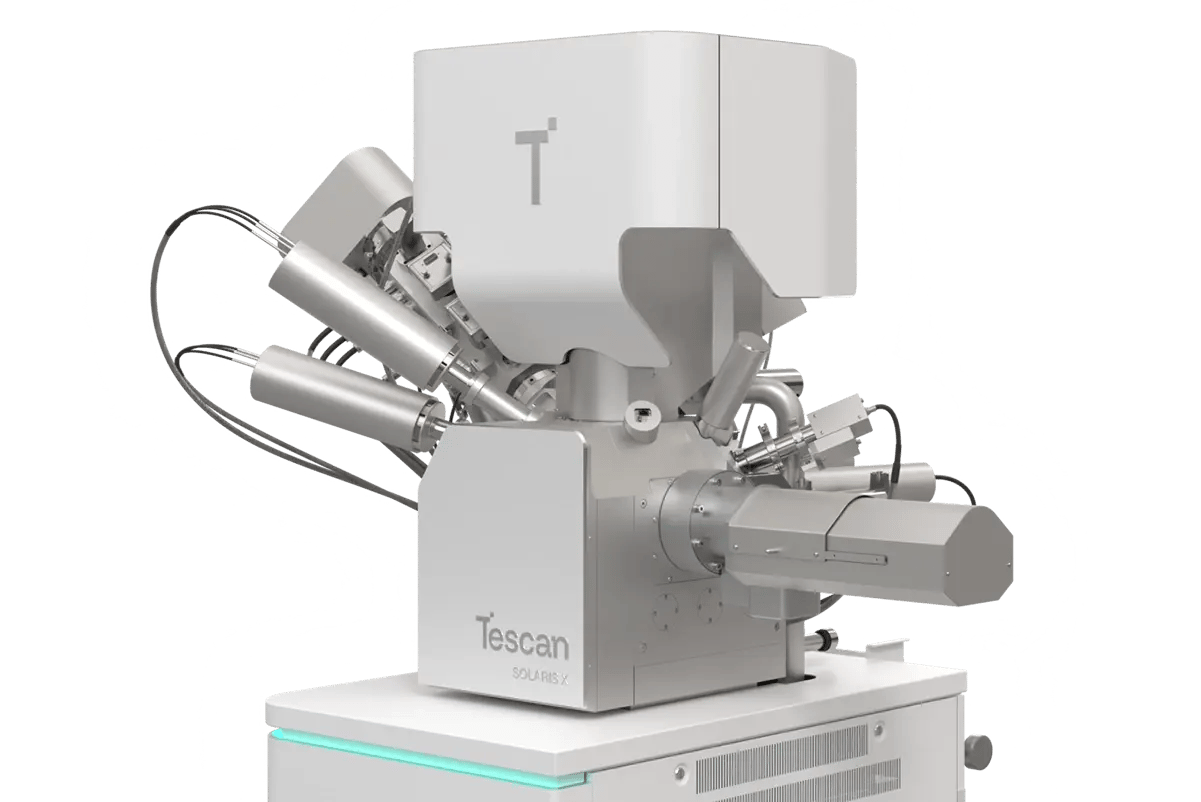

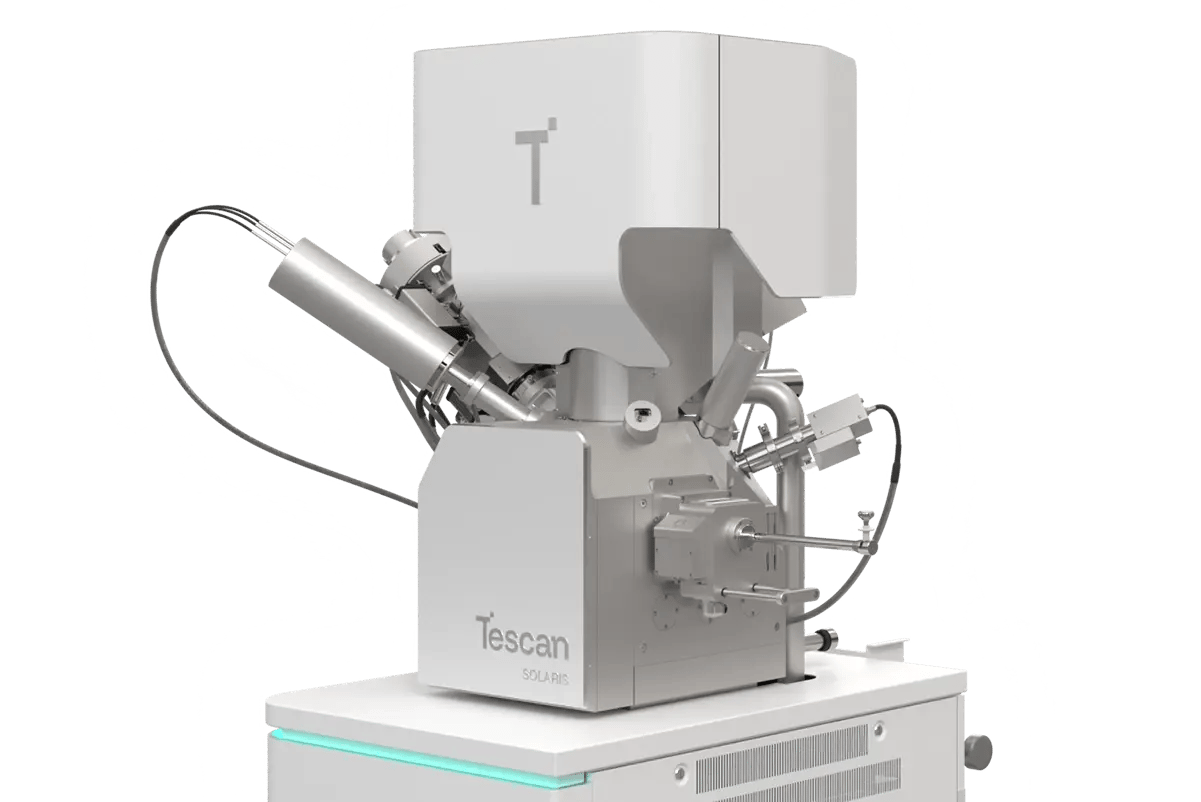

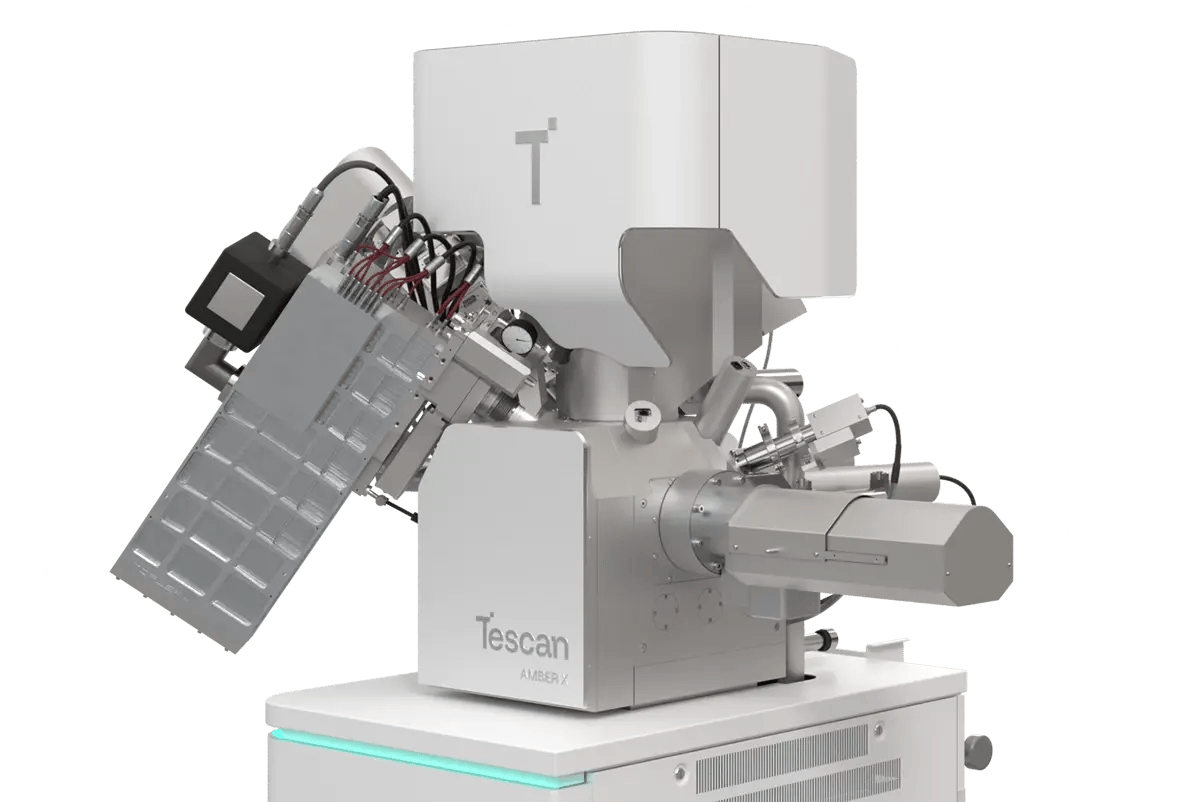

Combine mask-based plasma FIB milling with Rocking Stage tilting to achieve fast, clean, and repeatable cross sections of complex semiconductor samples. This workflow increases throughput and improves surface quality without the need for coatings or extra polishing.

- Physical masks: Reshape the beam–sample interaction for high-current milling with fewer artifacts

- Rocking Stage: Tilts the sample during polishing to reduce curtaining in curved or multi-material regions

- Versatile workflow: Delivers reliable results across OLEDs, BGAs, MEMS, and TEM lamella