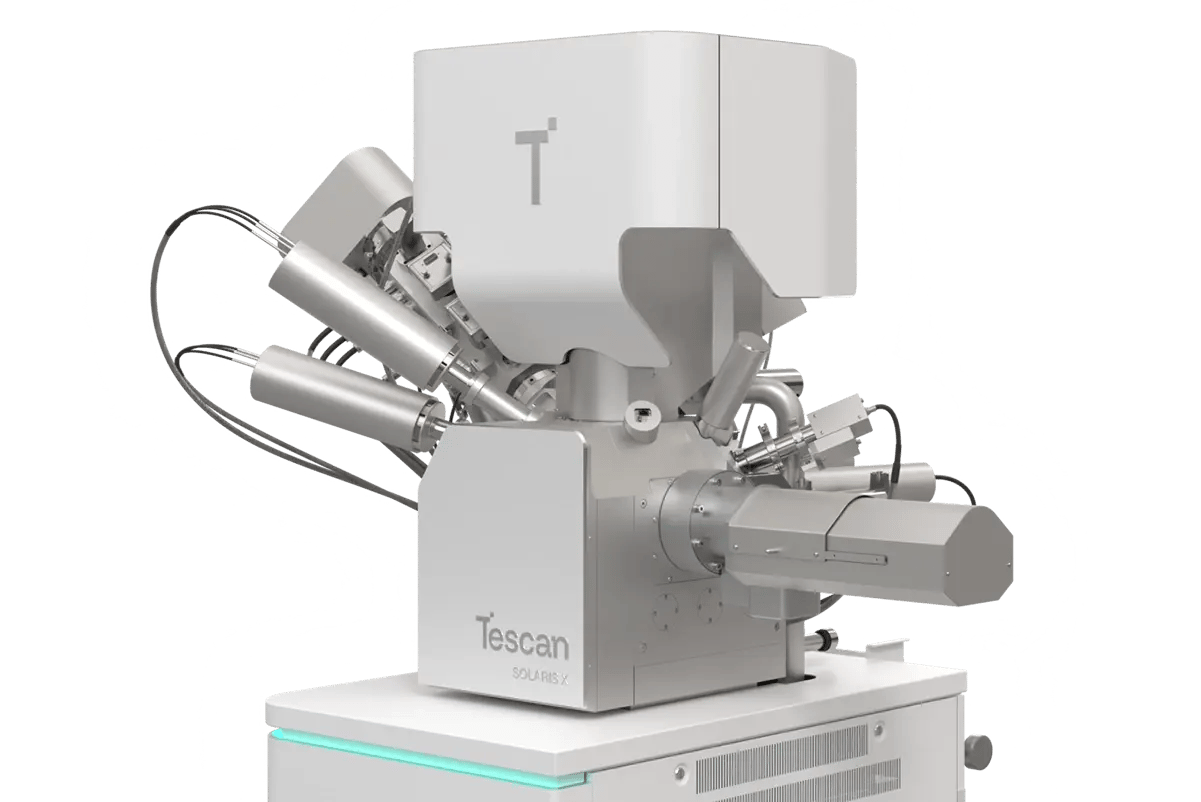

Tescan SOLARIS X 2 with Rocking Stage

Tescan SOLARIS X 2 with Rocking Stage combines high-throughput Xe plasma FIB milling with simultaneous SEM observation to deliver smooth, artifact-free cross sections in complex semiconductor structures.

The integrated rocking stage introduces tilt in the plane of the cross section, reducing curtaining and enabling precise endpointing during polishing.

- Rocking stage integration: enables alternating-angle milling for smoother surfaces

- Continuous SEM/BSE observation: supports real-time monitoring and accurate endpoint detection

- Xe plasma FIB technology: provides fast material removal for large-area cross sections

- Improved surface integrity: preserves interfaces in solder bumps, TSVs, and copper pillars

- Streamlined workflow: eliminates repositioning steps and reduces preparation time