Formation protocols define SEI properties and long-term performance. Tescan’s multimodal workflows reveal how different formation strategies influence stability and capacity.

- Characterize SEI morphology and chemistry with SEM, STEM, and ToF-SIMS

- Compare cycling protocols across graphite–LFP cells

- Correlate fluorine infiltration, morphology, and performance retention

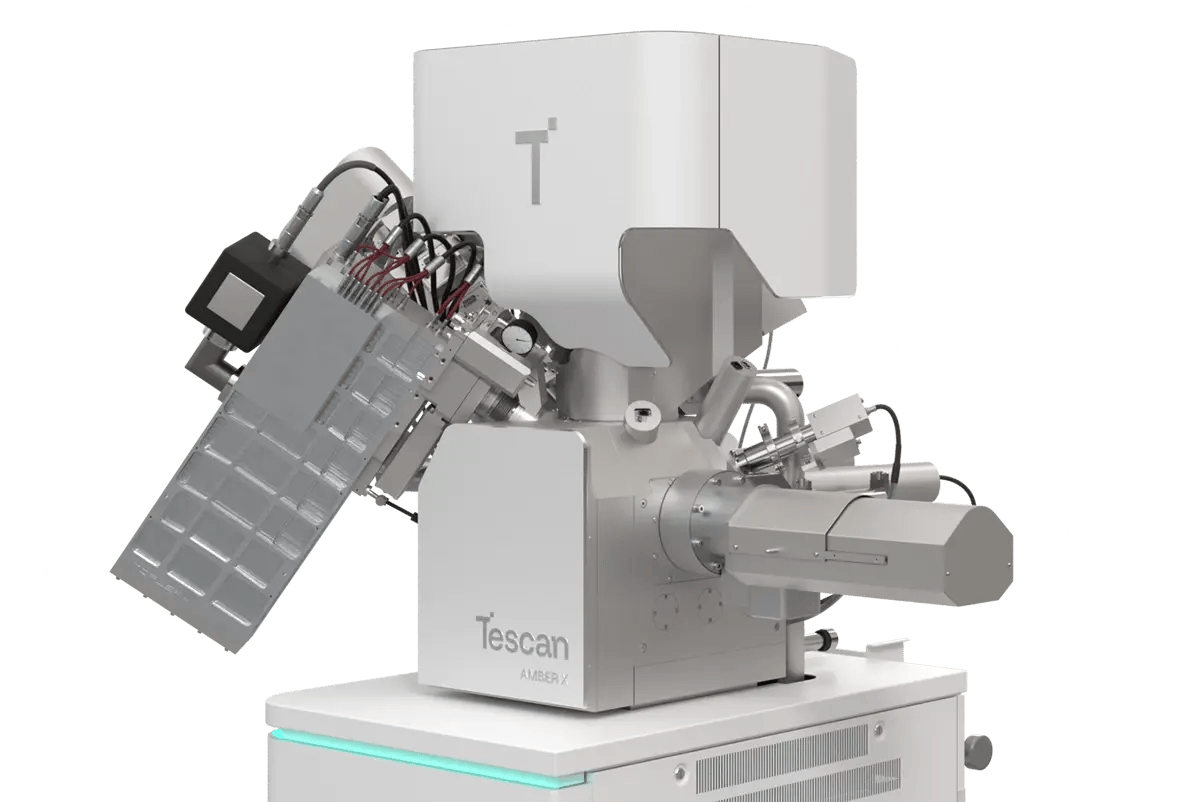

.webp?width=600&height=400&name=1_Plasma%20FIB%20cross%20section%20of%20a%20solid-state%20battery%2c%20showing%20the%20anode%2c%20separator%2c%20and%20cathode%20layers-1%20(1).webp)

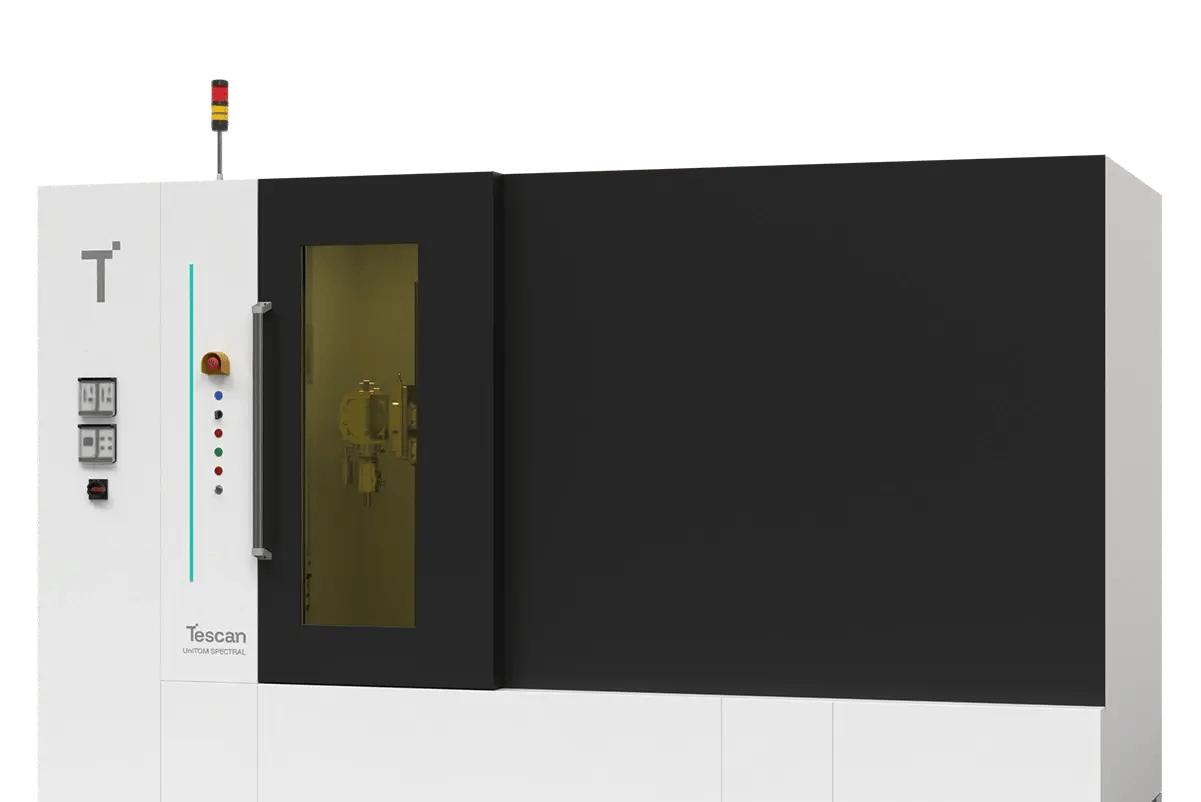

.webp?width=600&height=400&name=Nov%C3%BD%20projekt%20(1).webp)