Tescan AMBER X 2 - Multimodal FIB-SEM for Post-Mortem Battery Analysis

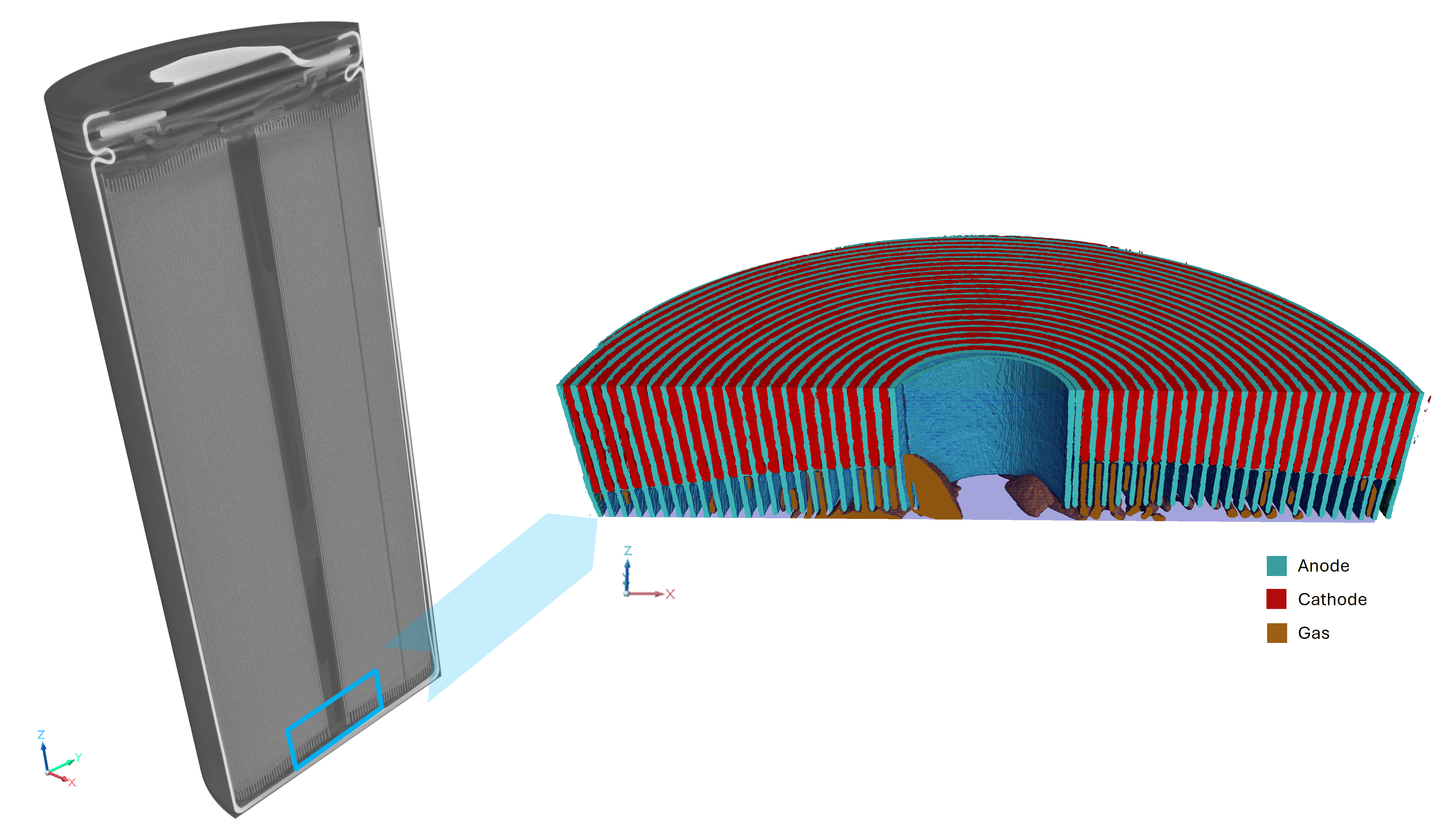

Tescan AMBER X 2 enables correlative structural and chemical analysis of lithium-ion battery components — ideal for SEI inspection, lamella preparation, and advanced degradation studies.

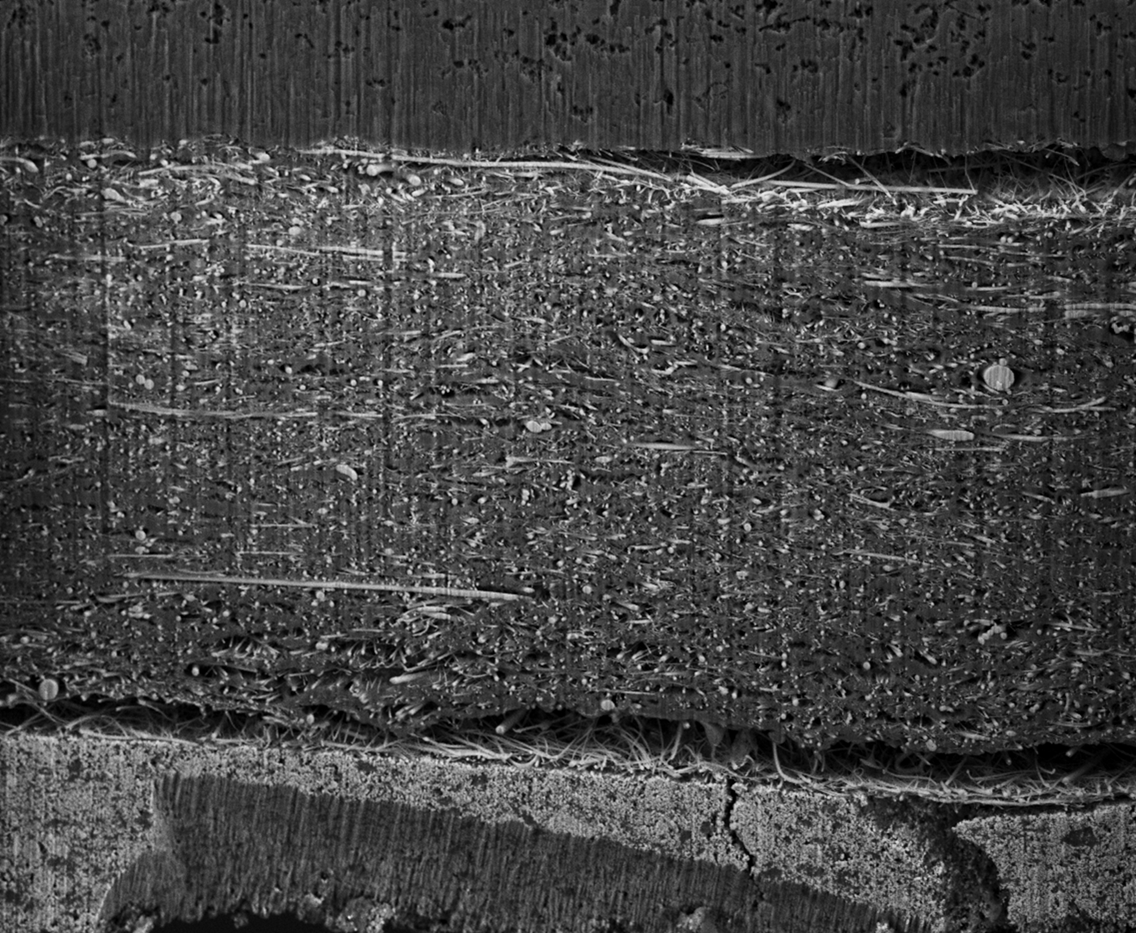

- Plasma FIB for fast lamella milling and volume sectioning

- Field-free UHR SEM with low-kV imaging for surface-sensitive features

- Integrated RSTEM for nanometer-scale subsurface analysis

- Compatible with inert sample transfer workflows