Tescan TENSOR - Precession-Assisted 4D-STEM Platform

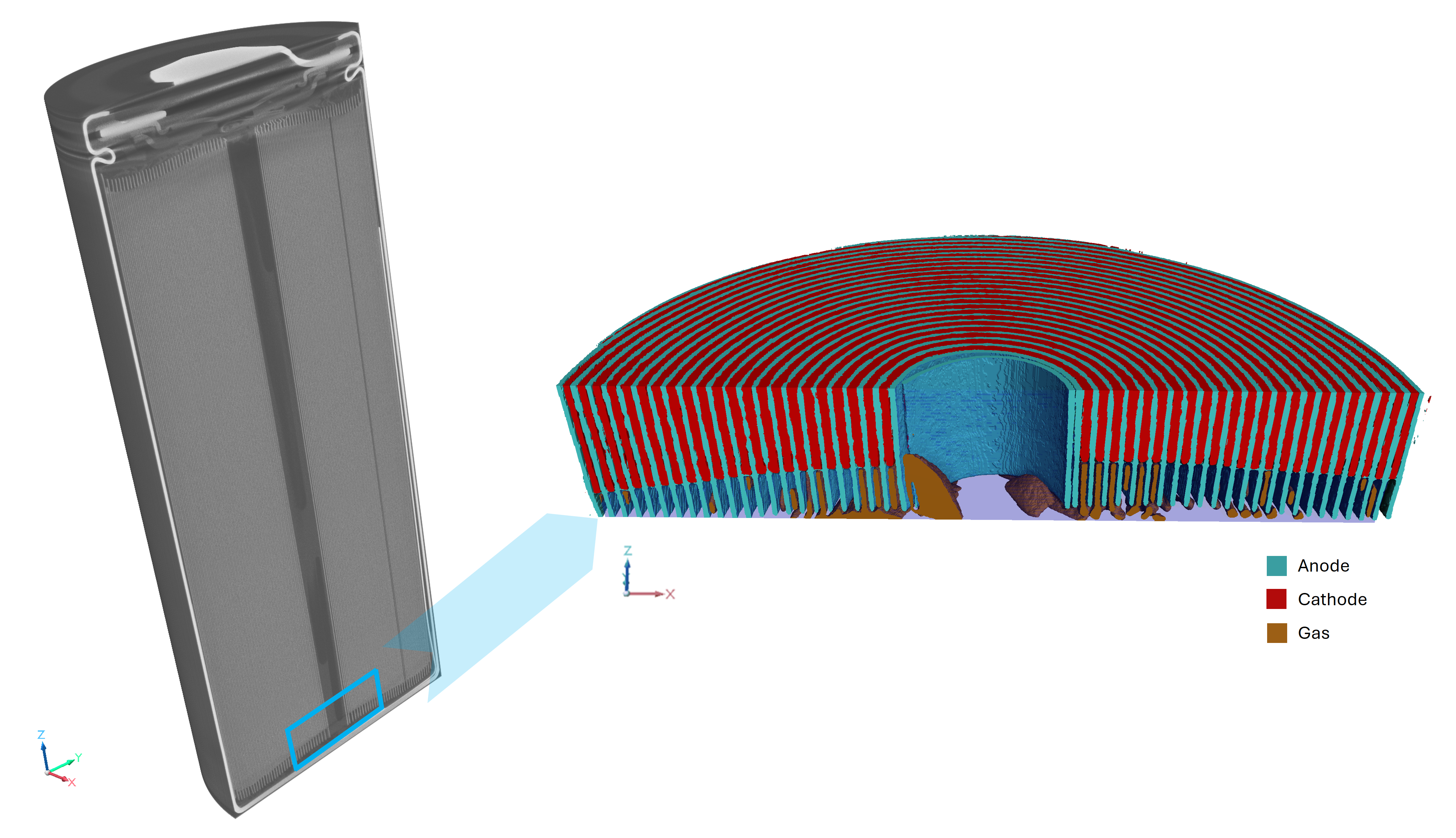

A fully integrated analytical scanning transmission electron microscope that captures imaging, diffraction, and EDS data simultaneously for multimodal nanoscale characterization.

- Precession-assisted diffraction for cleaner patterns and better phase indexing

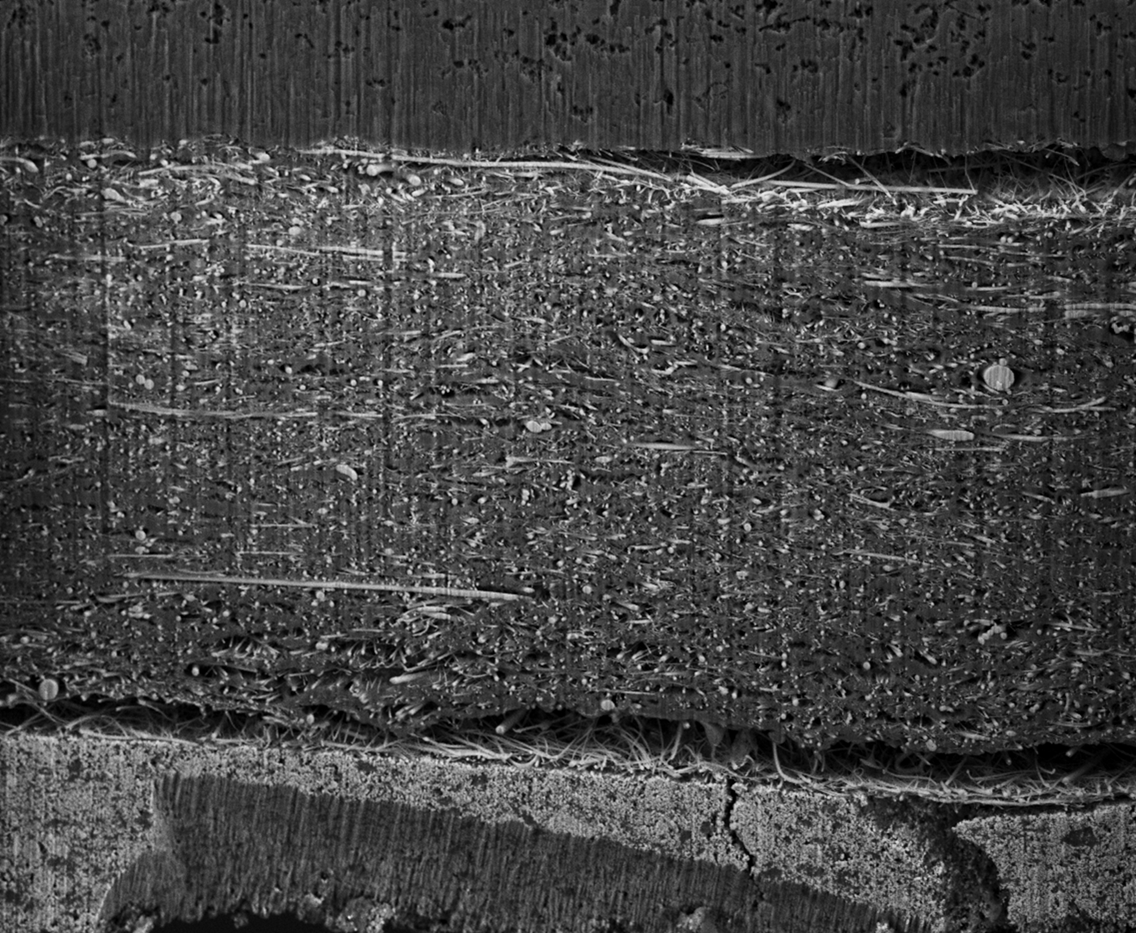

- Real-time orientation and phase mapping with nanometer spatial resolution

- Compatible with large fields of view and automated workflows for battery R&D