Tescan AMBER X 2

Tescan AMBER X 2 combines high-resolution SEM imaging, FIB milling, and multimodal analysis tools — making it ideal for interface characterization in advanced energy storage materials.

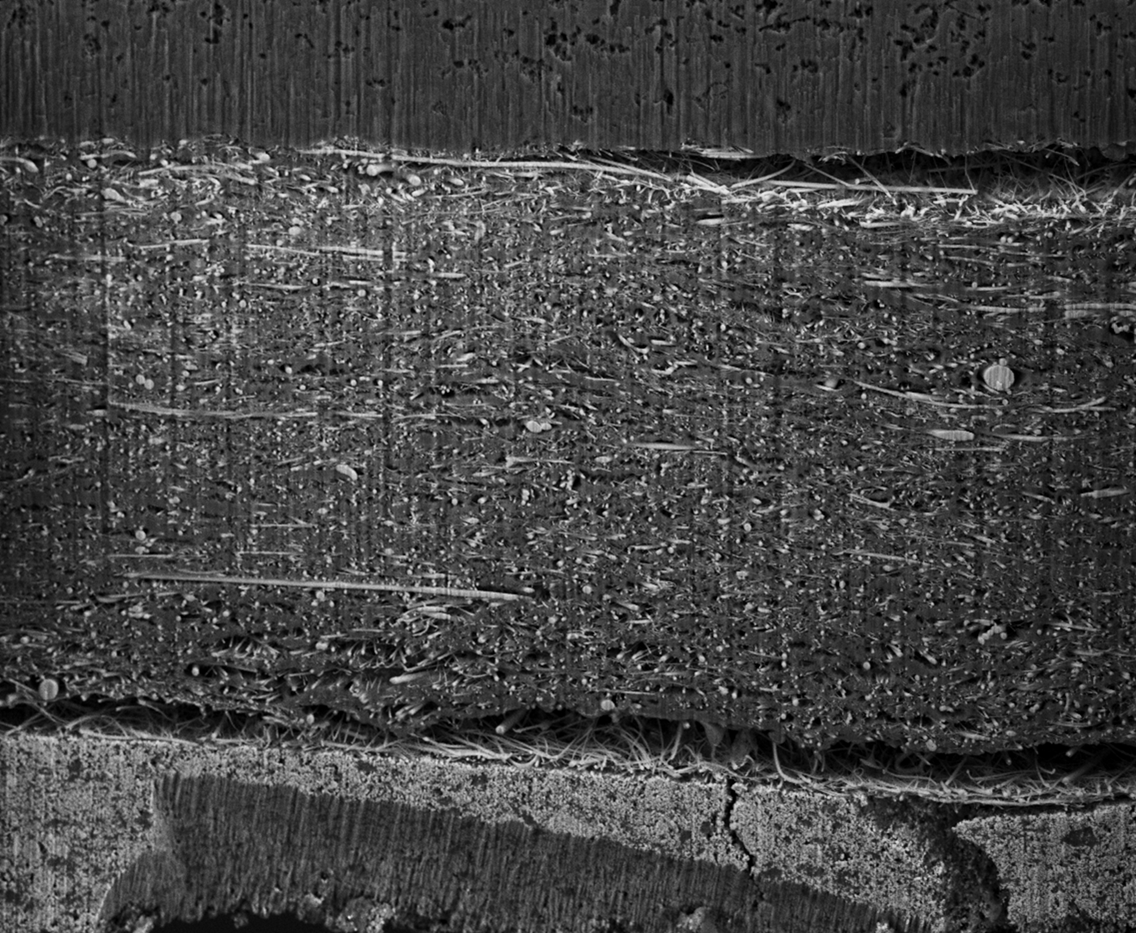

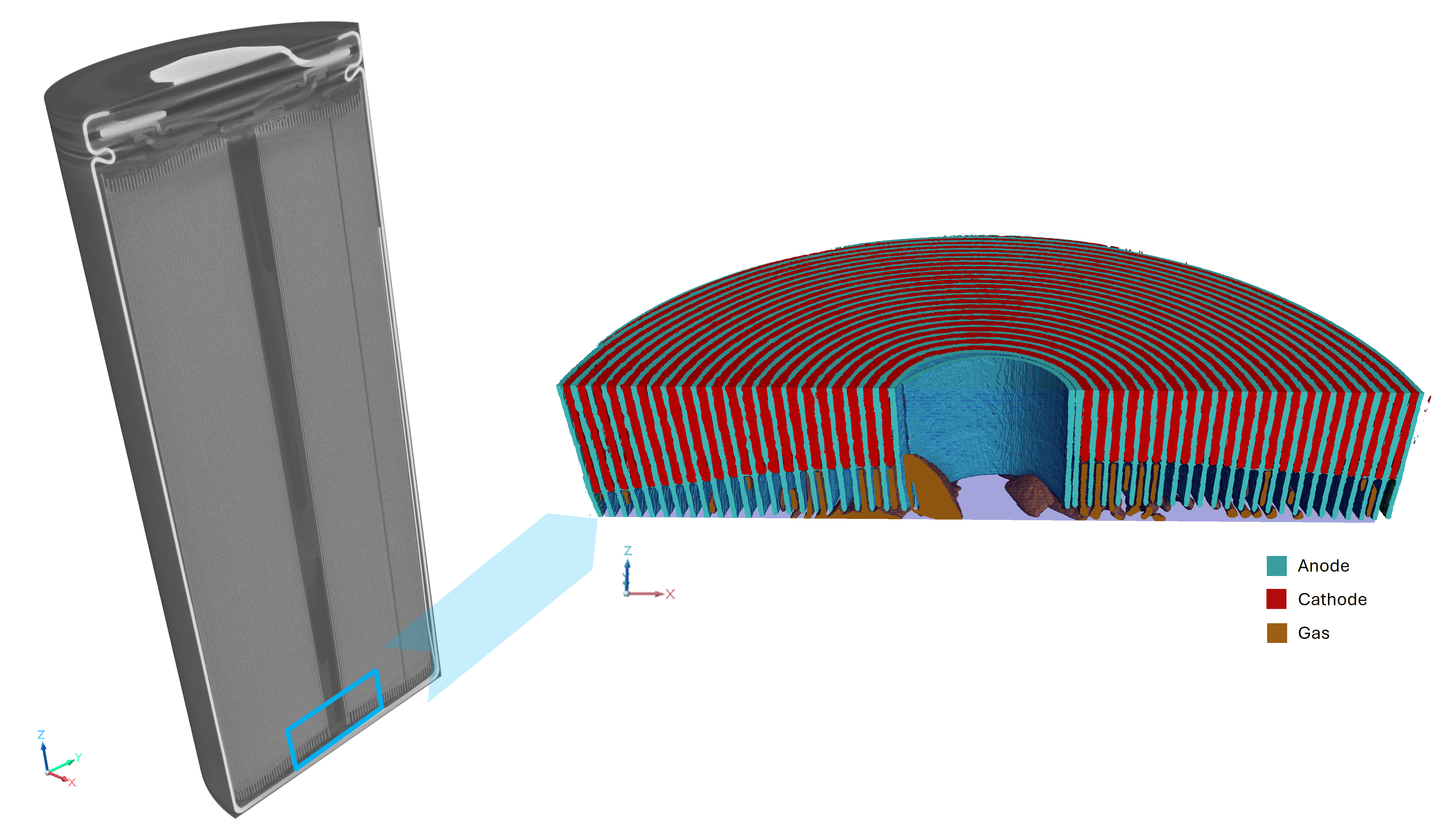

- Plasma FIB for fast, clean sectioning of battery stacks

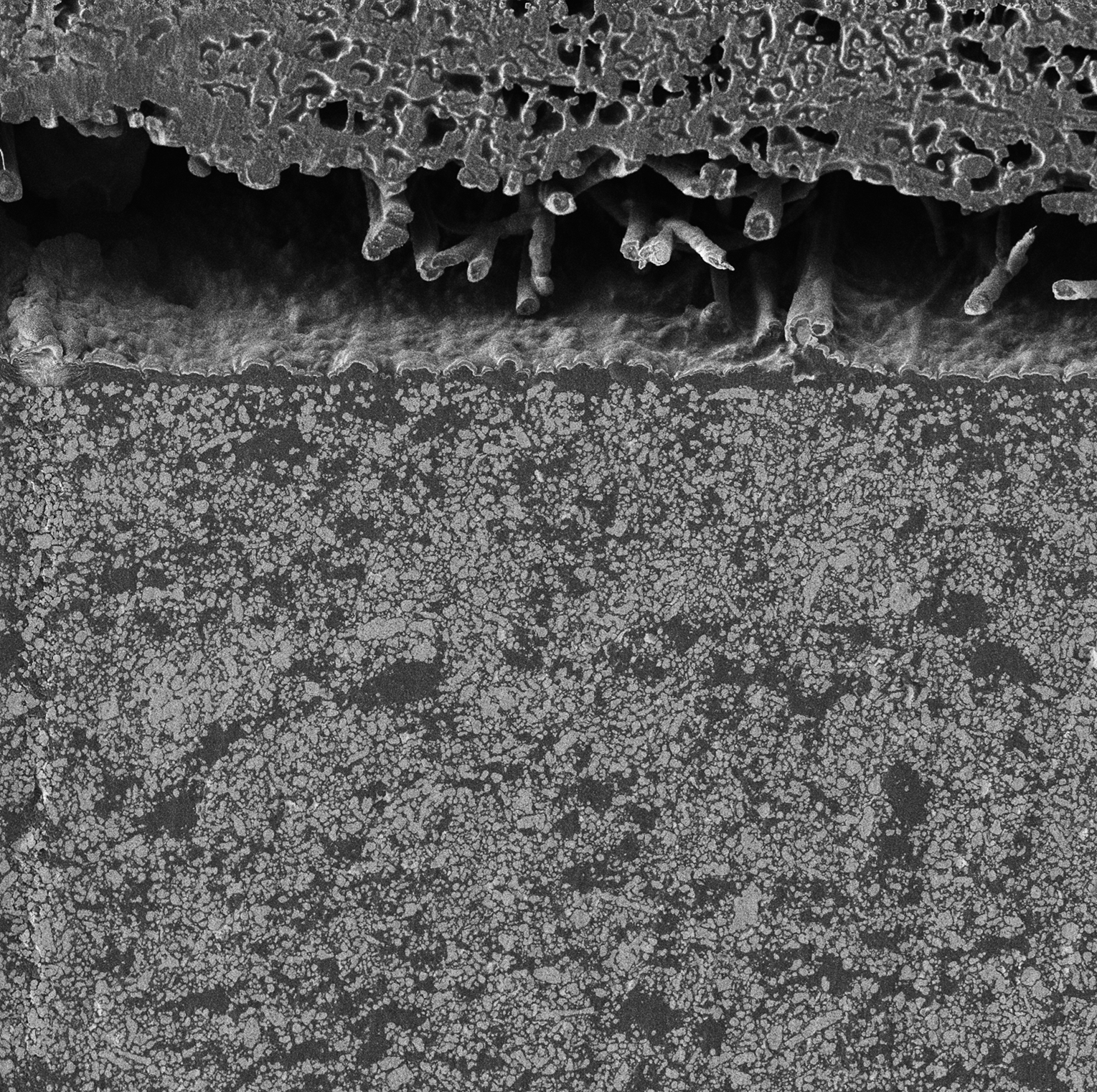

- Field-free SEM for low-kV, high-contrast surface imaging

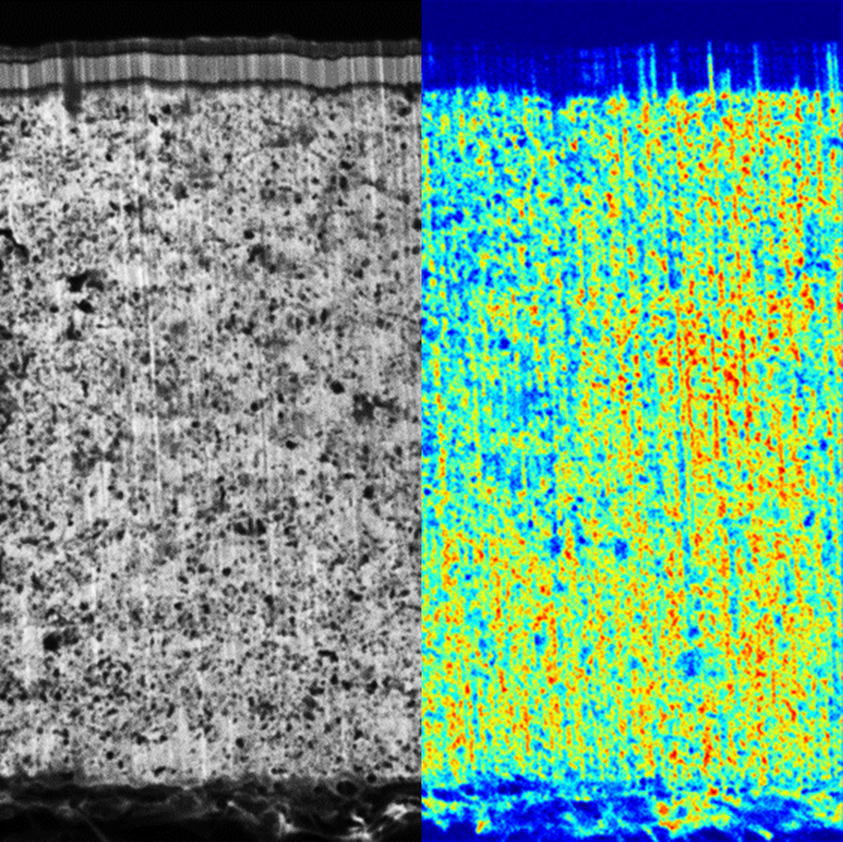

- Integrated STEM mode for nanoscale lamella inspection