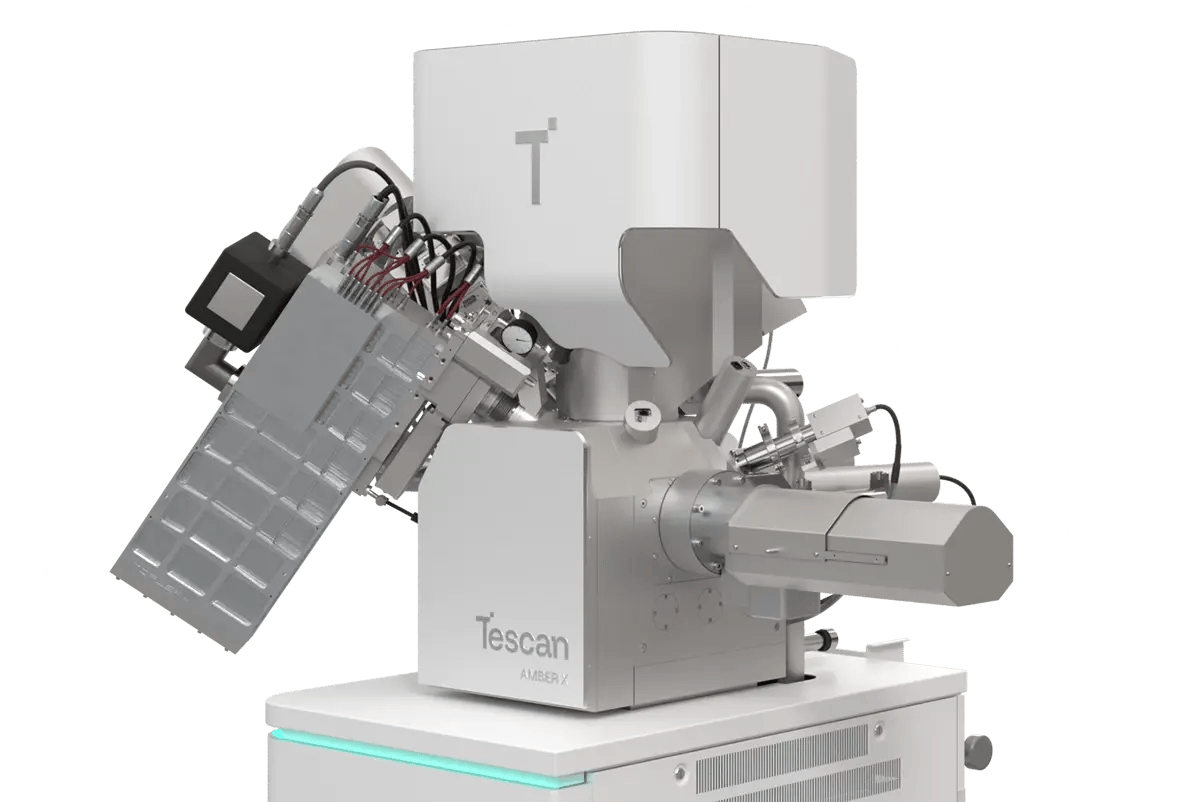

Electrode particle degradation drives capacity fade and internal resistance growth. Tescan AMBER X 2 with ToF-SIMS and Raman spectroscopy enables full structural and chemical analysis of degradation processes.

- Visualize exfoliation and fracturing in anodes and cathodes

- Map lithium trapping and chemical inhomogeneity in 3D

- Correlate microstructural and chemical data for targeted improvements

.webp?width=1032&height=680&name=1_Surface%20examination%20of%20exfoliation%20signs%20on%20degraded%2c%20cycled%20graphite%20anode%20particles%20(1).webp)

%20(1)%20(1).webp?width=470&height=354&name=Nov%C3%BD%20projekt%20(7)%20(1)%20(1).webp)