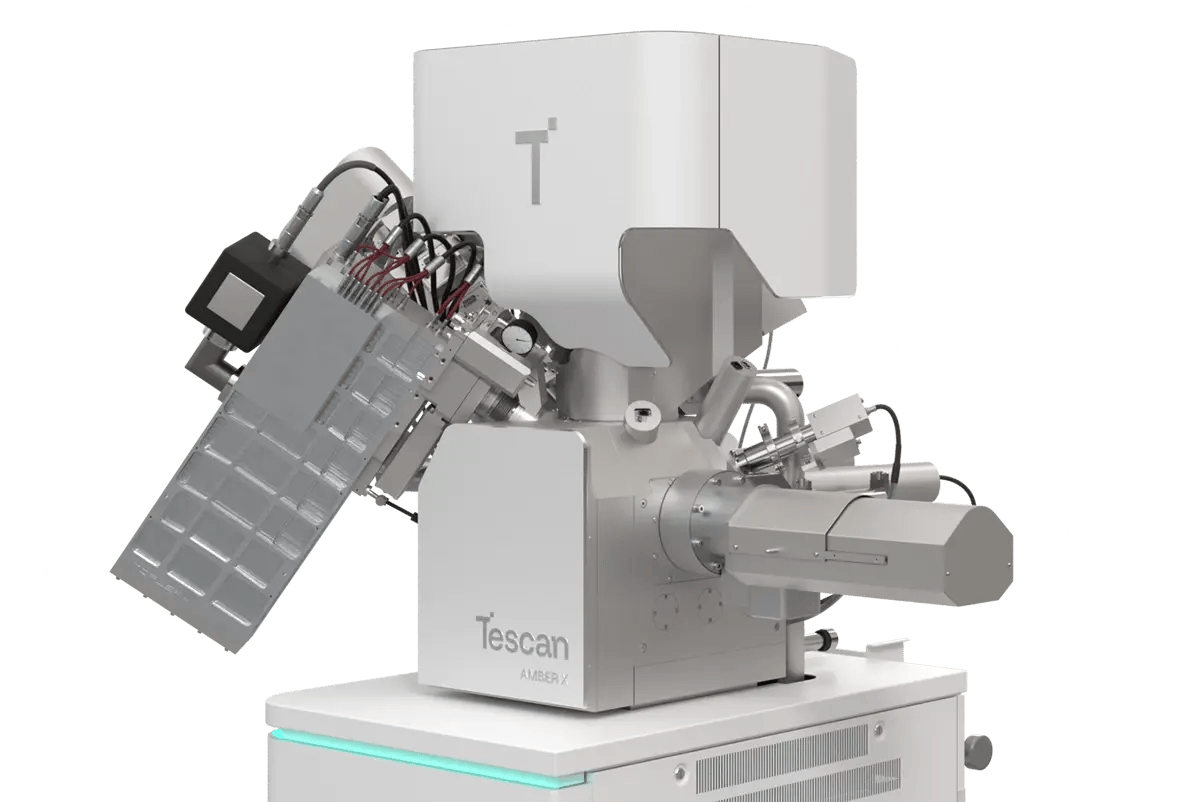

Tescan AMBER X 2

Tescan AMBER X 2 combines plasma FIB milling with ultra-high-resolution SEM and integrated chemical analysis tools — ideal for studying electrode materials at every scale.

- Field-free UHR SEM with low-kV imaging for surface-sensitive features

- Plasma FIB for fast volume sectioning and lamella preparation

- Integrated STEM for nanometer-scale subsurface analysis

- Compatible with inert atmosphere transfer for air-sensitive samples

%20(1)%20(1).webp?width=470&height=354&name=Nov%C3%BD%20projekt%20(7)%20(1)%20(1).webp)