Tescan UniTOM XL

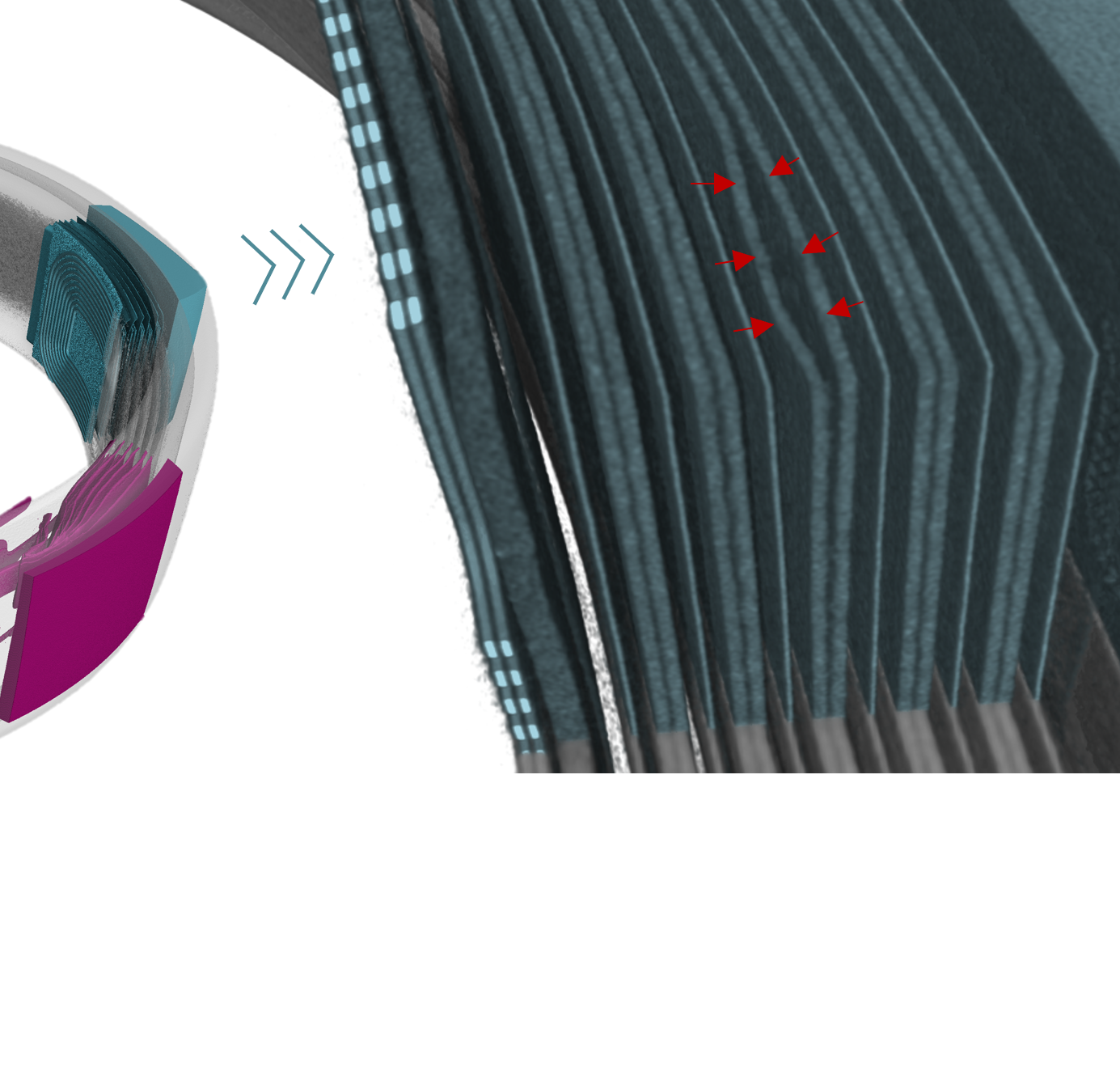

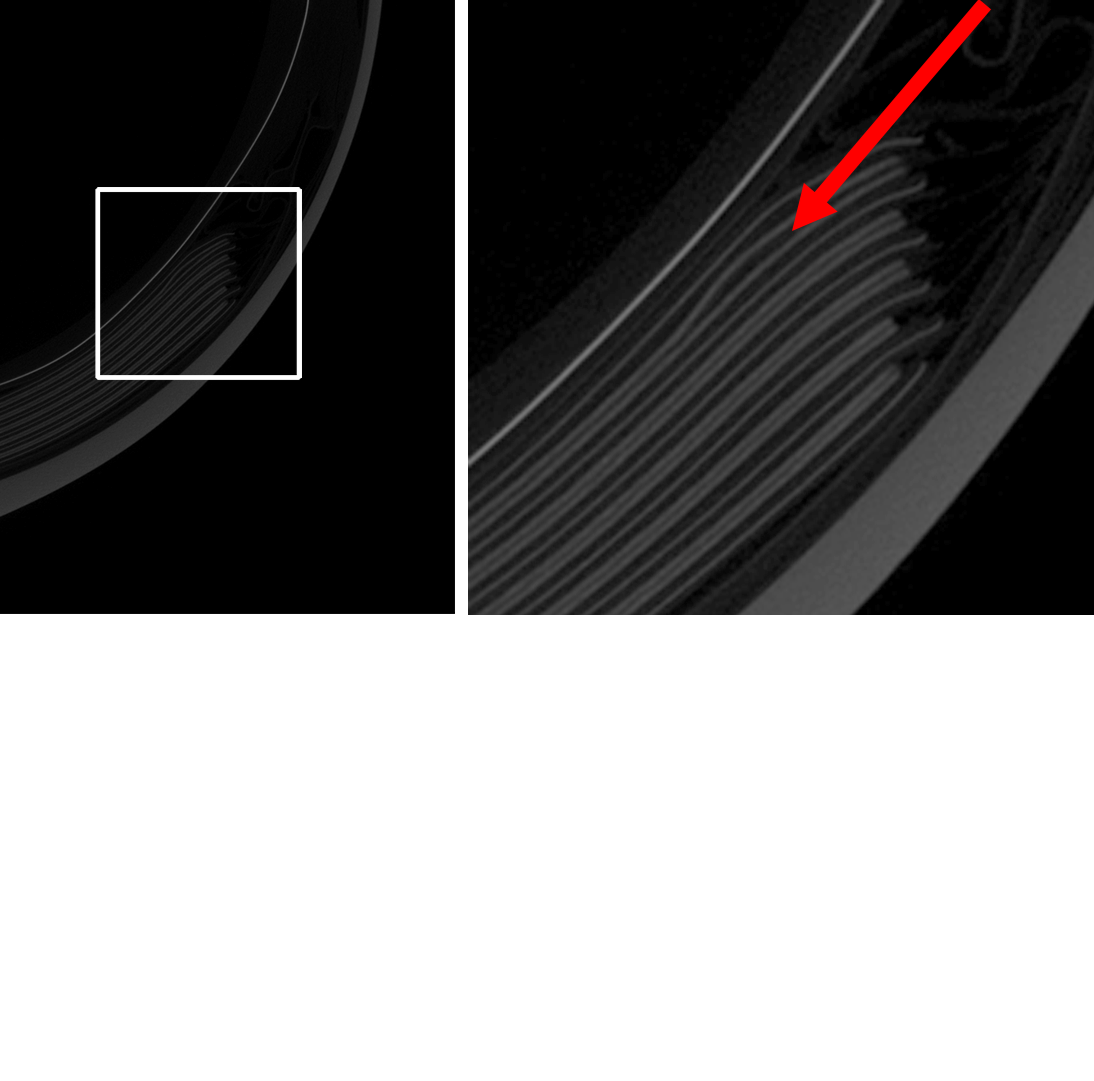

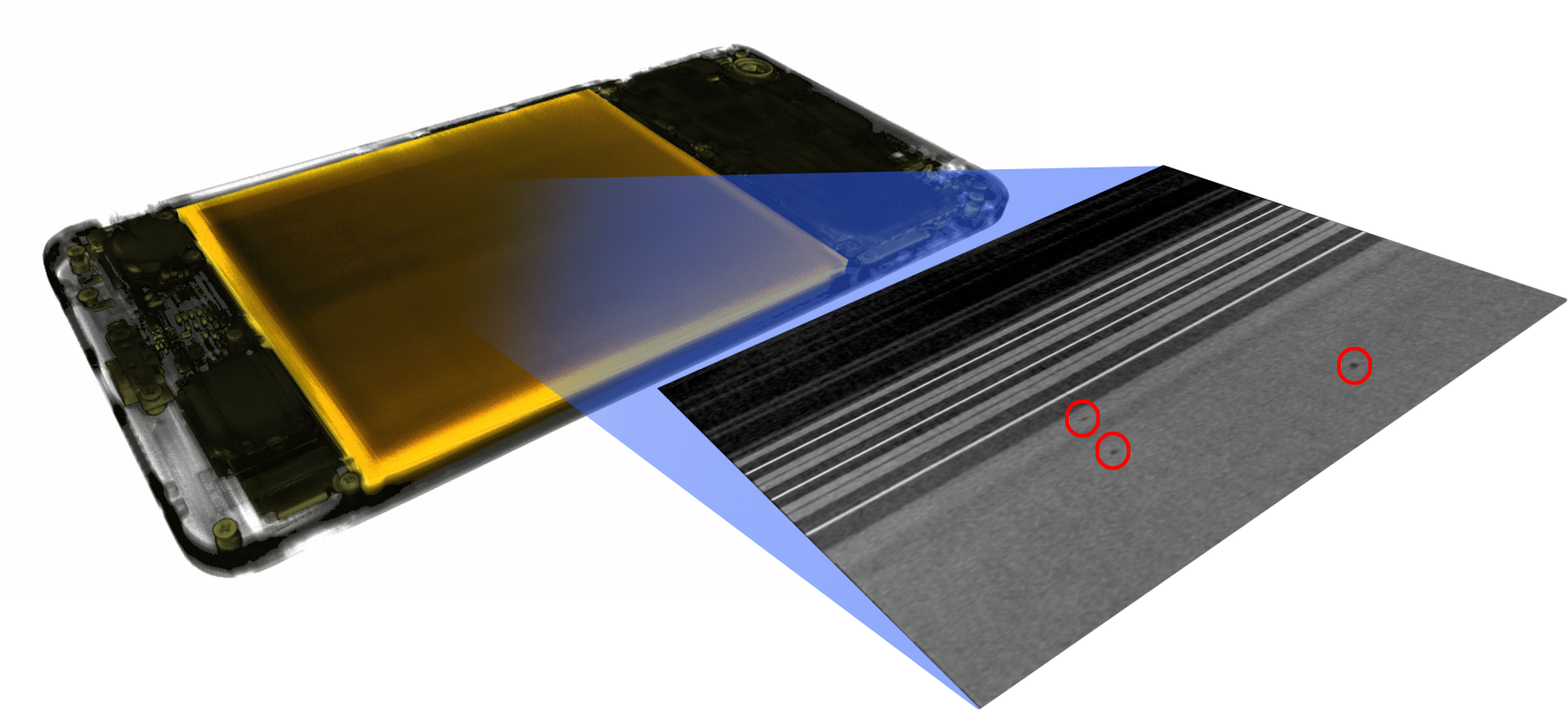

TESCAN UniTOM XL provides multiscale, non-destructive imaging for electronics and battery systems. With support for large sample sizes and high-resolution volume-of-interest scanning, the system is ideal for detailed analysis of internal battery defects in fully assembled devices.

- Supports samples up to 100 cm × 60 cm for large-scale imaging

- Multiscale Volume-of-Interest scanning for high-detail analysis within large objects

- Versatile micro-CT for diverse sample types with no special preparation needed

.webp?width=470&height=456&name=Nov%C3%BD%20projekt%20(7).webp)

.webp?width=470&height=456&name=Nov%C3%BD%20projekt%20(8).webp)

.webp?width=470&height=456&name=Nov%C3%BD%20projekt%20(9).webp)

.webp?width=2000&name=MICRO_UniTOM_XL_2%20(2).webp)