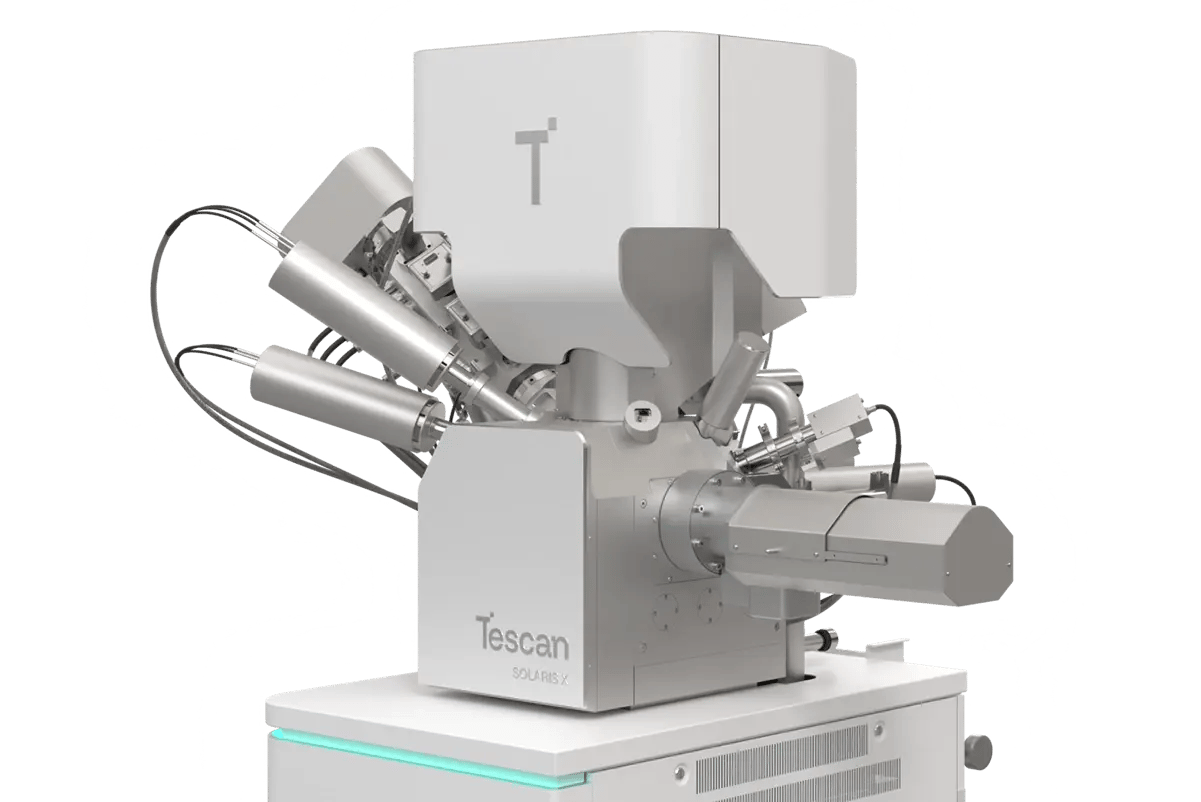

Tescan SOLARIS X 2 with Mistral™ Xe Plasma FIB: Versatile, User-friendly FIB-SEM platform

Tescan SOLARIS X 2 delivers fast, high-current Xe plasma FIB milling and precise low-current thinning, ensuring optimal thickness and structure preservation. Its inert Xe ion source enables clean lamella preparation for advanced semiconductor failure analysis without the contamination that occurs with gallium FIB sample preparation.

High resolution SEM imaging enables locating regions of interest, monitoring sample thinning in real-time and inspecting final thinned samples to verify compatibility with downstream STEM and EDS workflows. Mistral™ Xe Plasma Column: supports fast bulk milling and delicate lamella thinning

- Inert ion beam avoids chemical artifacts and eliminates gallium implantation that occurs with traditional Ga+ FIB sample preparation

- Final thinning below 5 keV: minimizes amorphous damage at critical interfaces

- Real-time SEM imaging: enables pre-liftout lamella QC

- Wide range of beam currents enable both speed and precision in one system