Tescan UniTOM XL

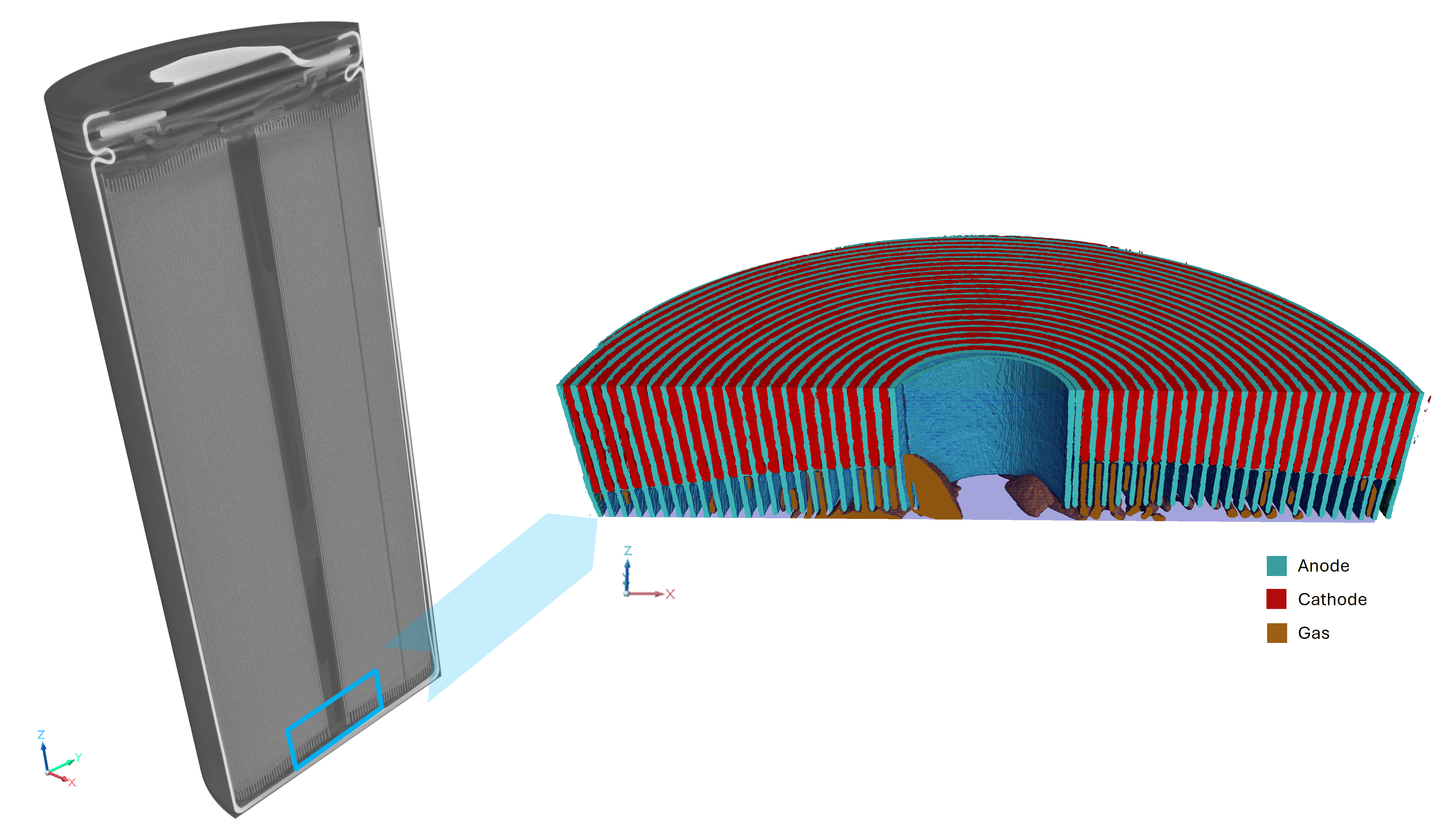

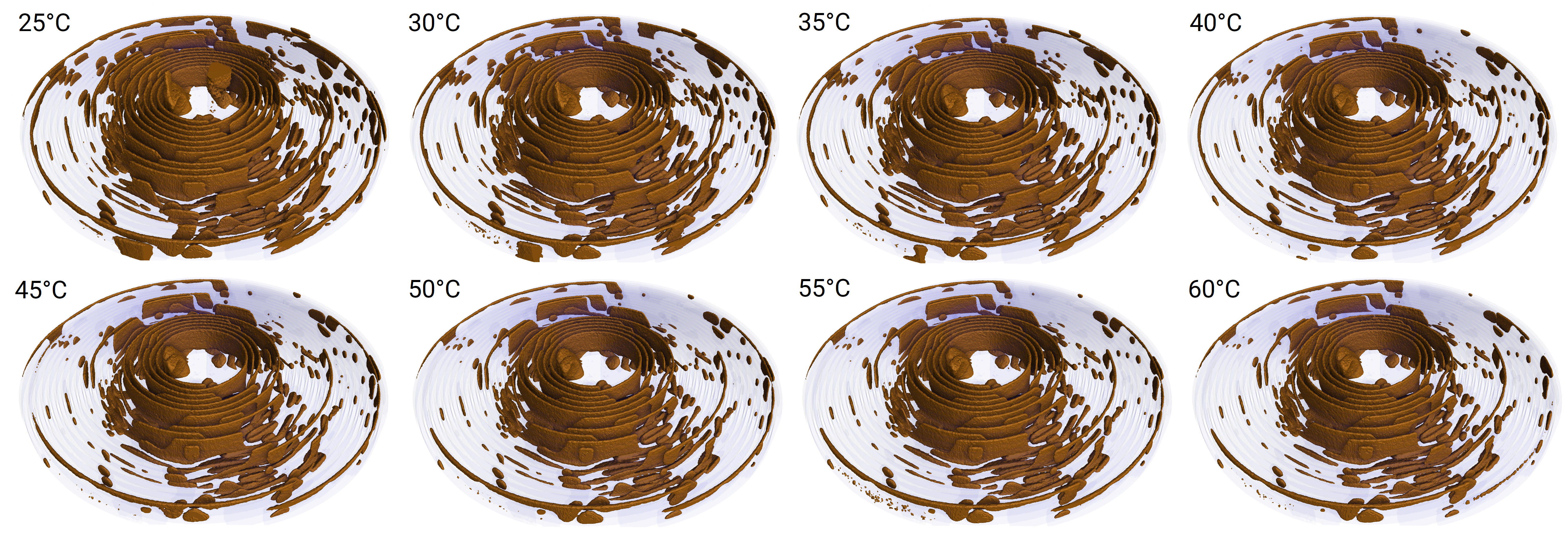

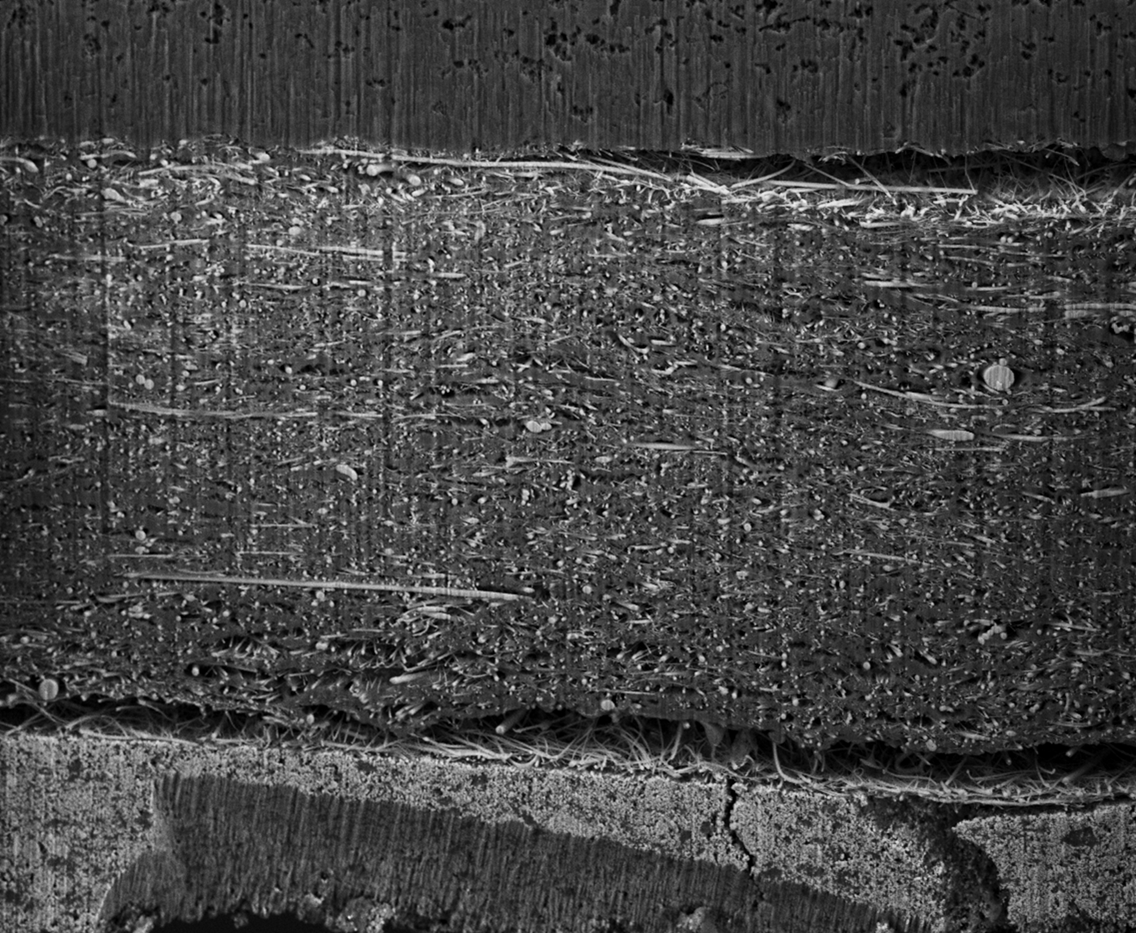

Tescan UniTOM XL combines in situ thermal control with high-resolution micro-CT to visualize internal battery behavior as it unfolds. Its advanced imaging workflow captures structural changes in intact cells across temperature cycles, making it a powerful tool for investigating failure mechanisms in lithium-ion batteries.

- In situ heating integration: enables synchronized temperature control during scanning.

- Time-lapse micro-CT: allows electrolyte dynamics visualization and reveals shifts in gas and electrode structure.

- Non-destructive acquisition: preserves cell integrity for repeatable testing.

- Flexible voxel resolution: captures both macrostructure and fine internal features.

- Stable imaging platform: reduces motion artifacts during lengthy or high-temperature scans.

- Advanced reconstruction tools: supports full-volume analysis across formats and time points.