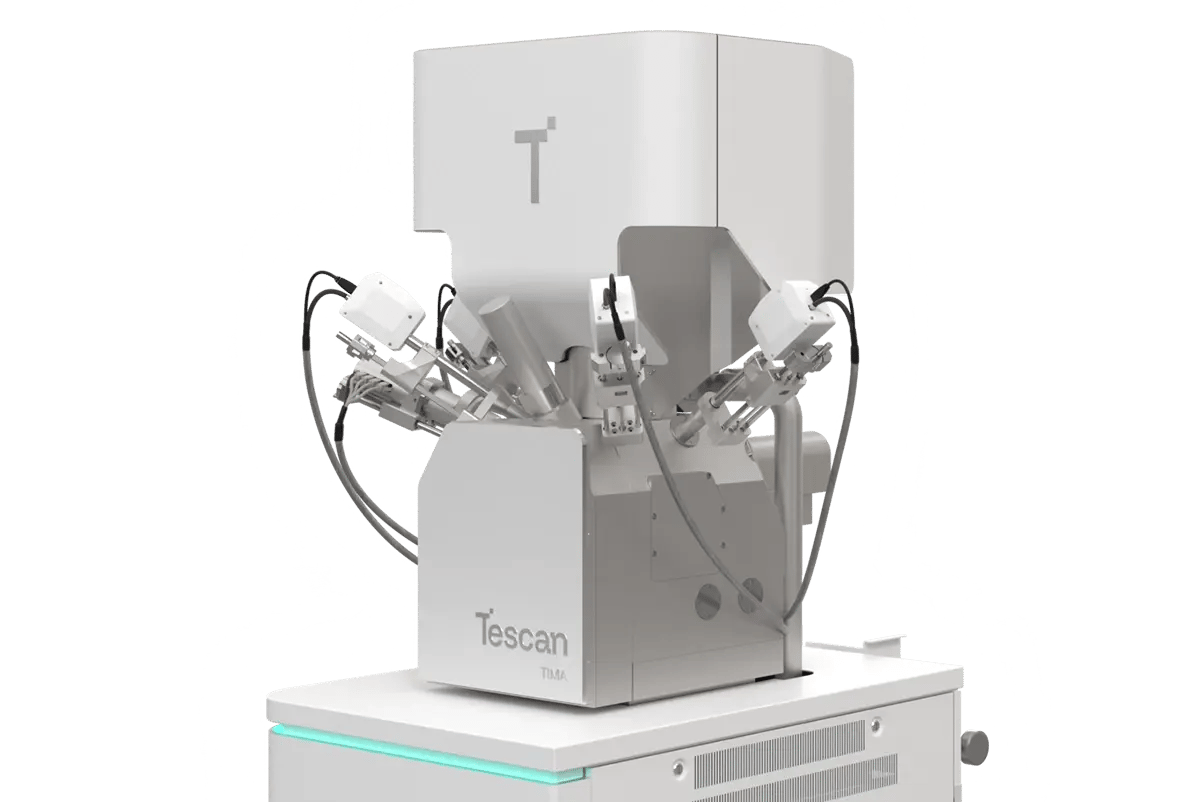

TESCAN TIMA

TESCAN TIMA provides integrated chemical and morphological analysis of multi-phase, heterogeneous materials — making it ideal for characterizing battery recycling output such as black mass.

- High-throughput EDS-based particle classification

- Quantitative liberation and association analysis

- Flexible scripting for custom phase categorization