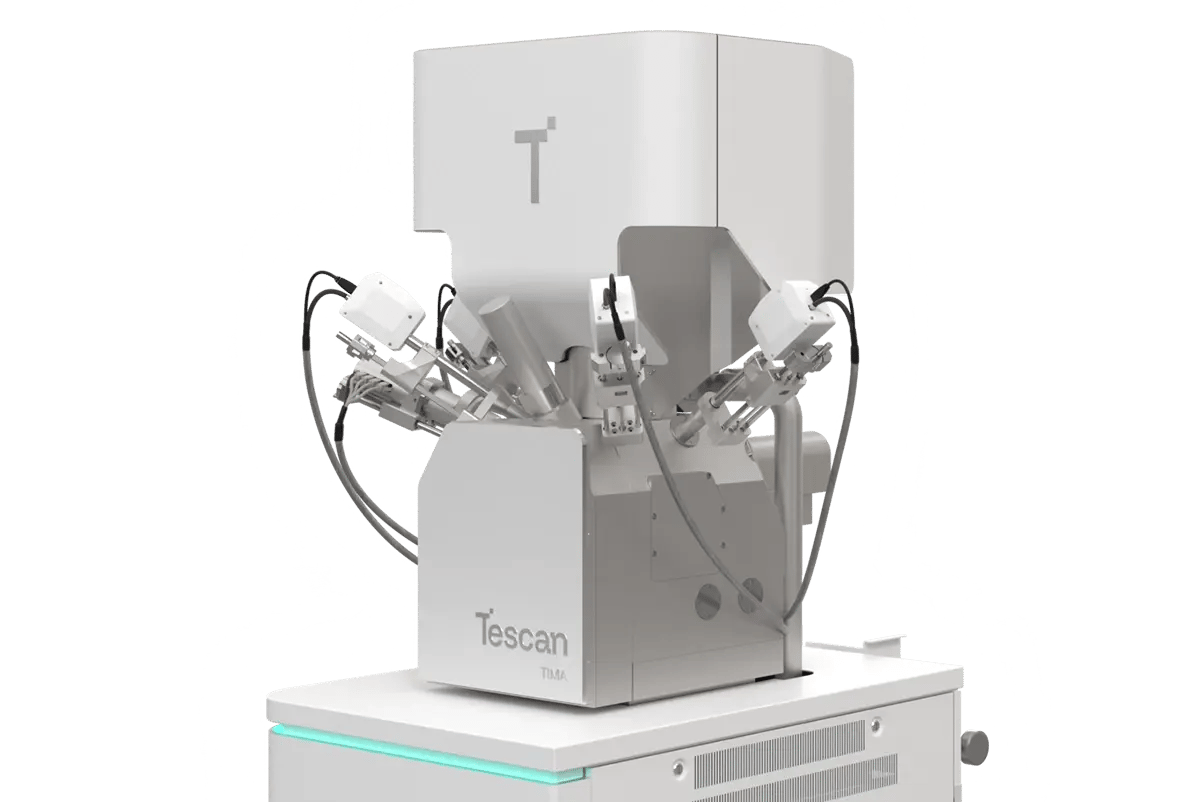

Lithium extraction requires accurate quantification of minerals that often look alike. Tescan TIMA provides automated, high-throughput mineralogical mapping to ensure reliable resource evaluation and process design.

- Differentiate spodumene and lepidolite from similar silicates

- Identify trace lithium phases such as amblygonite often missed by SEM

- Quantify liberation, grain size, and associations for process modeling