Tescan Plasma FIB-SEM – High-Throughput Xe+ Ion Milling

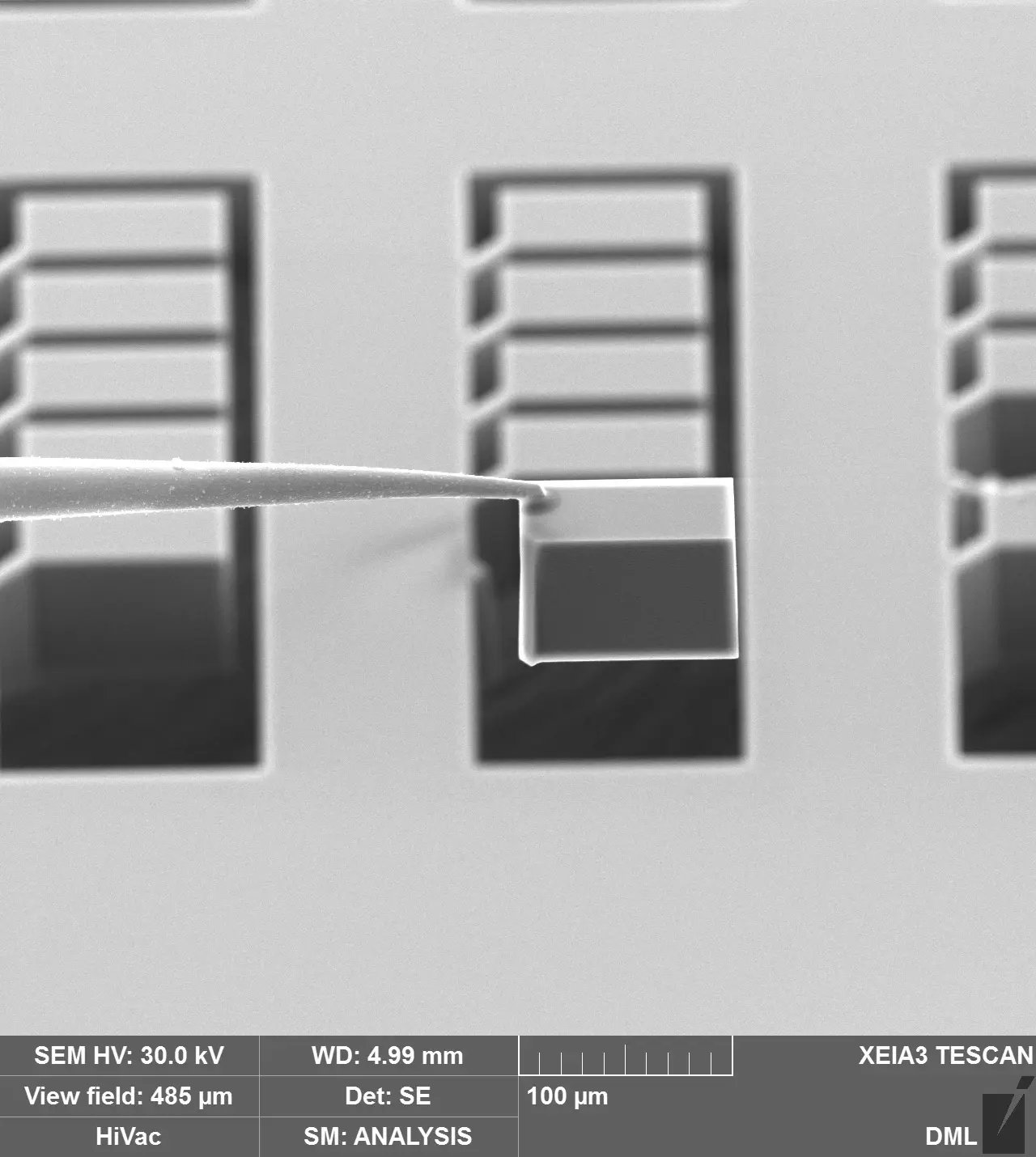

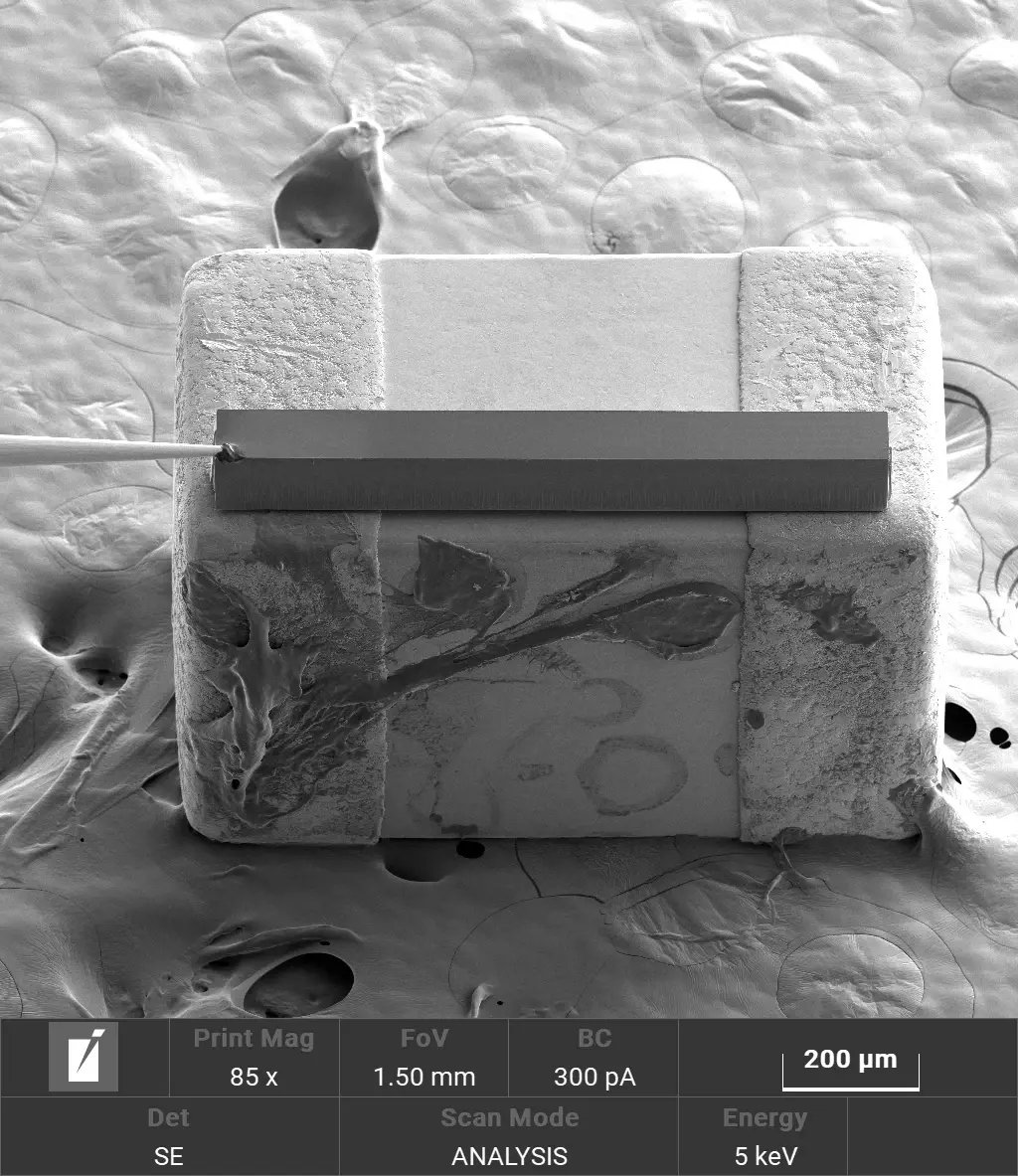

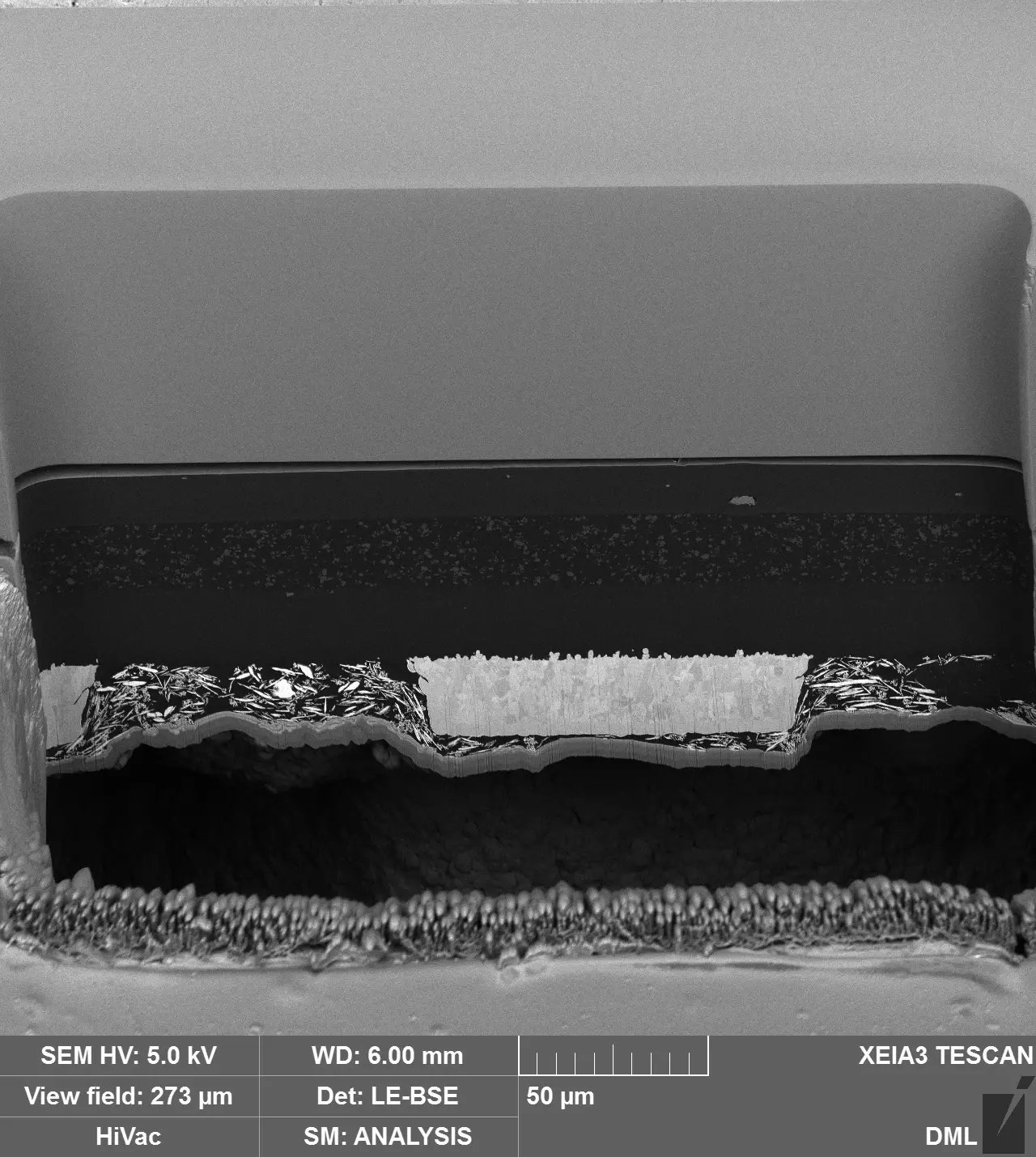

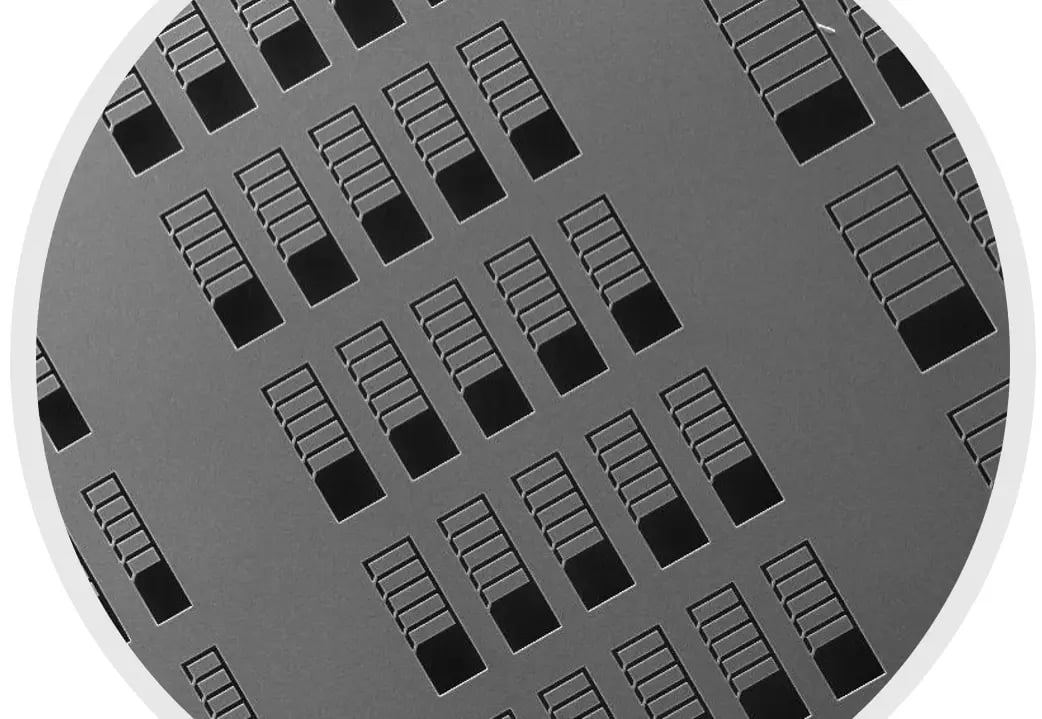

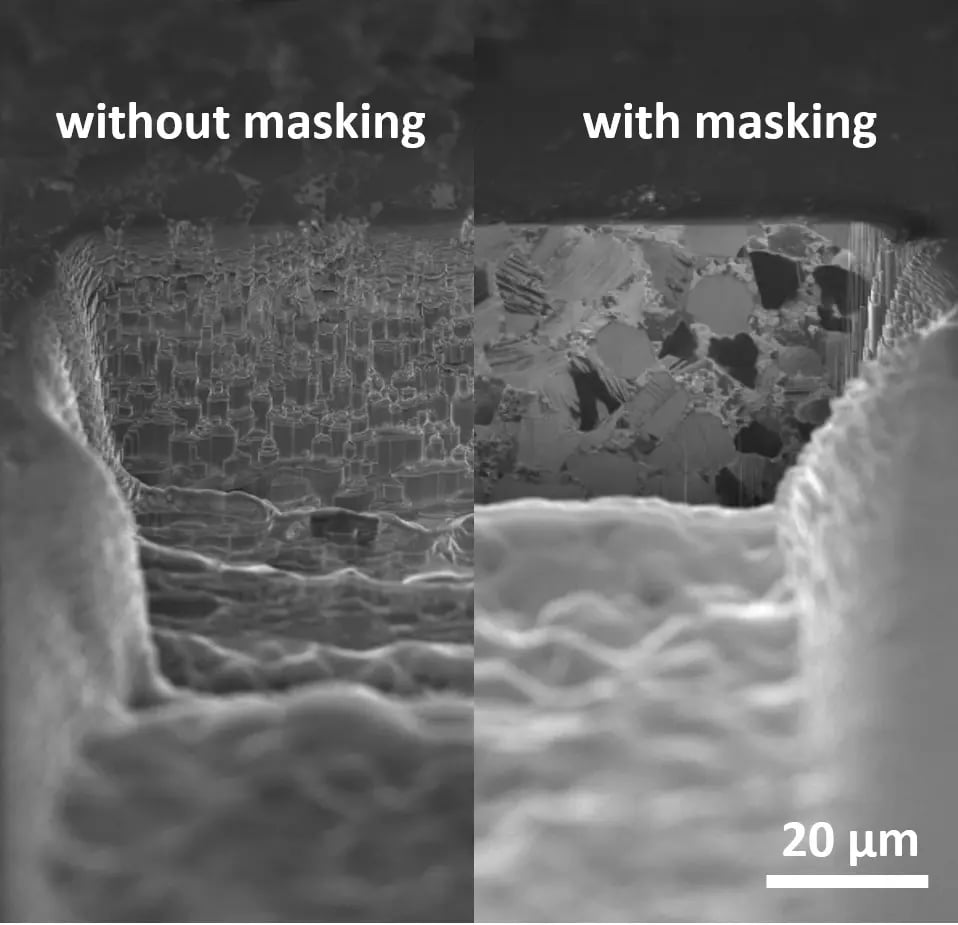

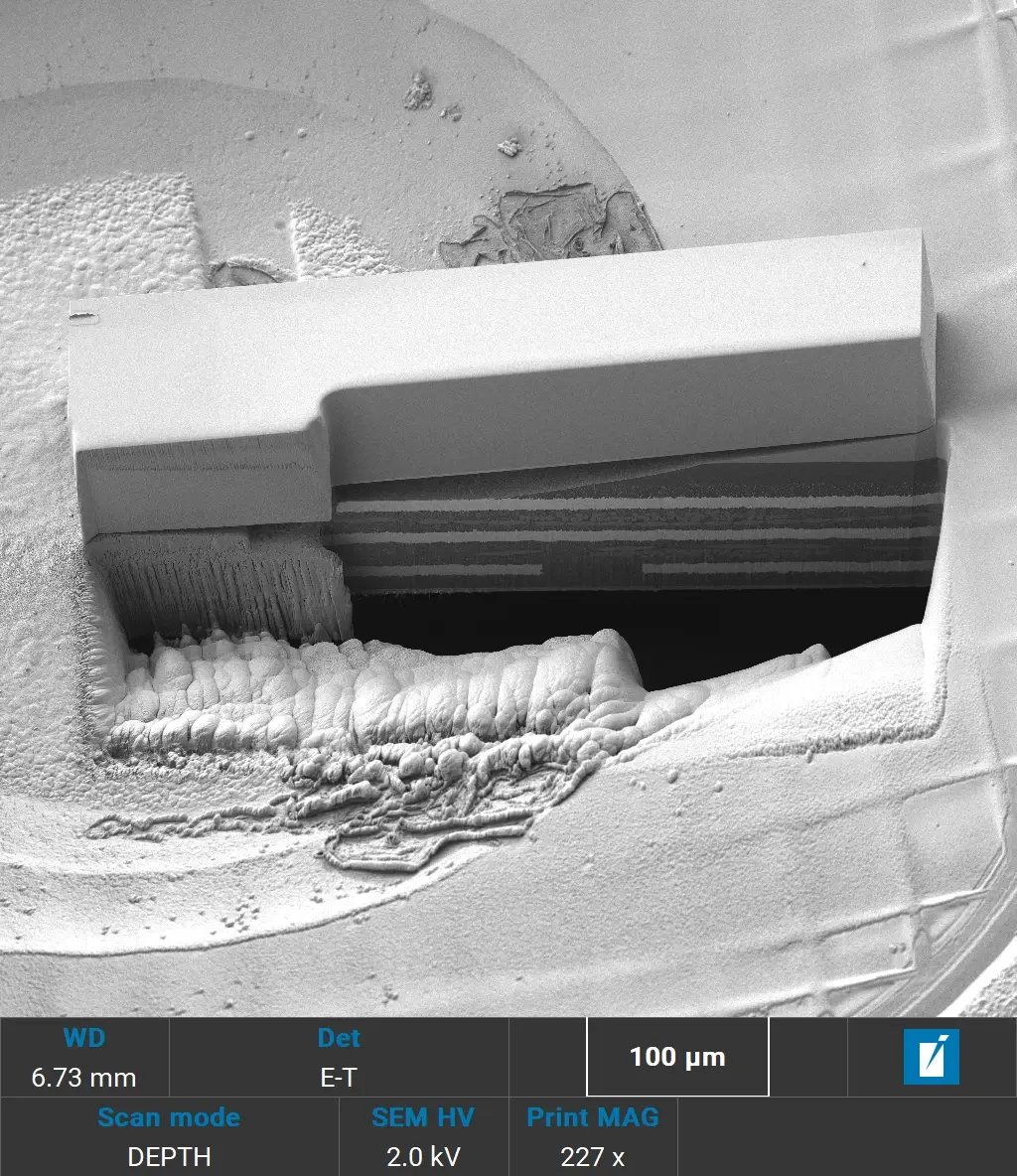

Tescan Plasma FIB-SEM systems use Xe+ ions for high-current milling and wide-area cross-sections. They integrate SEM imaging and Plasma FIB precision, enabling preparation of cross-sections hundreds of micrometers wide.

Analyze BGAs, TSVs, bond wires, OLEDs, and sensors with artifact-free surfaces, prepare TEM lamellae, and use live SEM endpoint detection for accurate targeting—all in one workflow.

- Xe+ Plasma FIB: high-current milling for wide cross-sections

- Integrated SEM: real-time endpoint detection

- Large-area prep: up to 1 mm without artifacts

- Ga-free source: minimizes amorphization

- Multi-application use: FA, OLEDs, TSVs, lamella prep