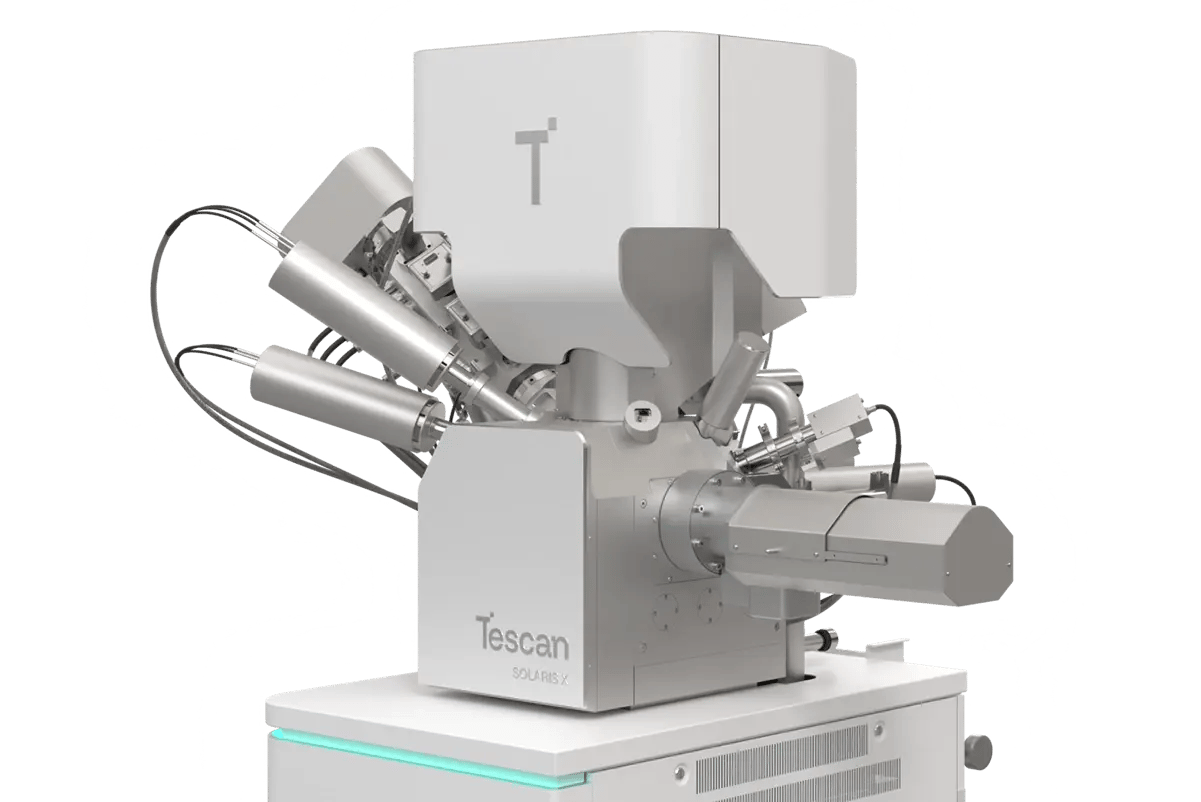

Tescan SOLARIS X with Xe Plasma FIB-SEM

Tescan SOLARIS X combines high-throughput Xe plasma FIB milling with high-resolution SEM imaging to prepare large, geometry-true cross-sections of complex semiconductor devices. Its wide current range and precision control make it ideal for both rapid bulk removal and fine surface polishing.

- Xe plasma FIB: enables fast removal of millimeter-scale volumes without thermal damage

- Integrated SEM column: delivers high-resolution imaging for surface inspection and analysis

- Large-current range (up to 3 μA): supports both speed and precision in a single system

- Geometry-true sectioning: ensures clean, artifact-free surfaces ready for SEM/EDS analysis

- Automation-ready platform: reproducible workflows for semiconductor failure analysis