Tescan UniTOM HR with Submicron Resolution and 4D Dynamic CT

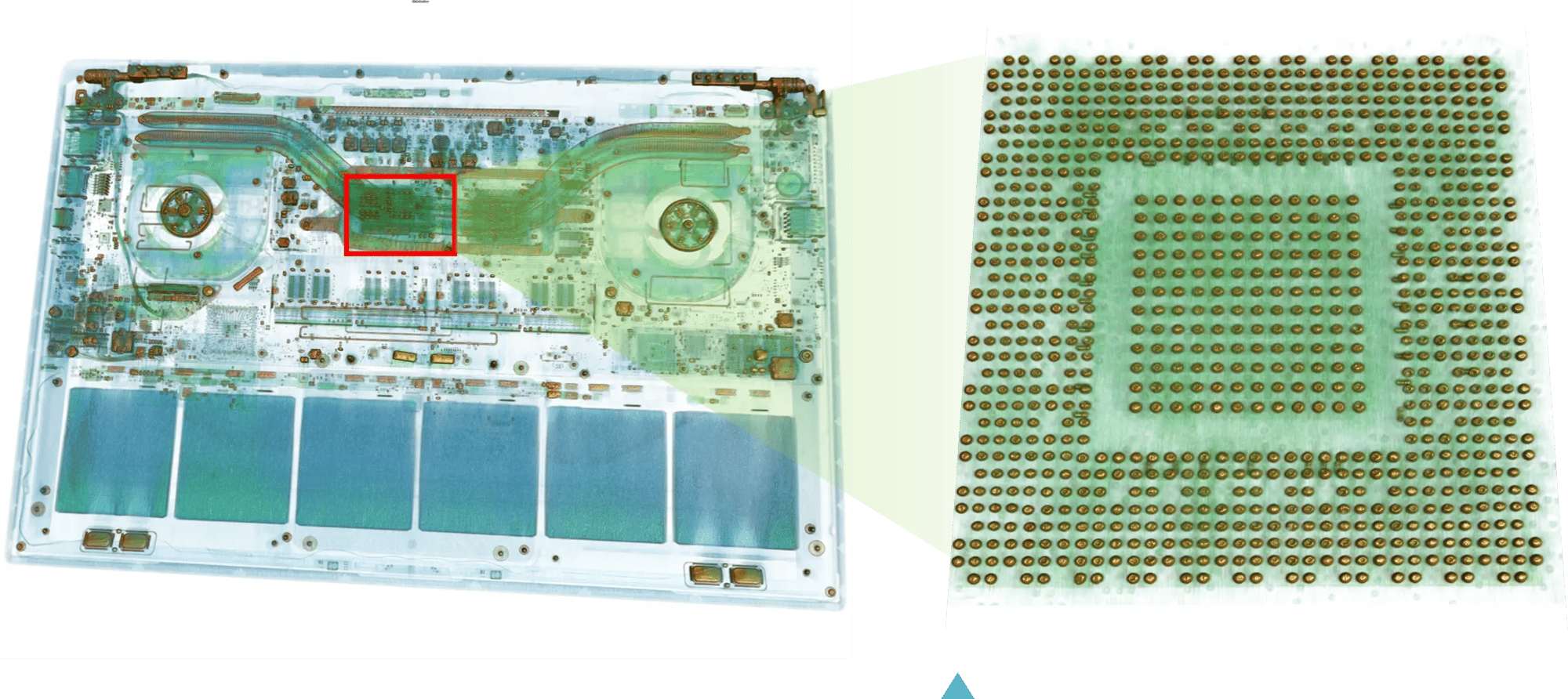

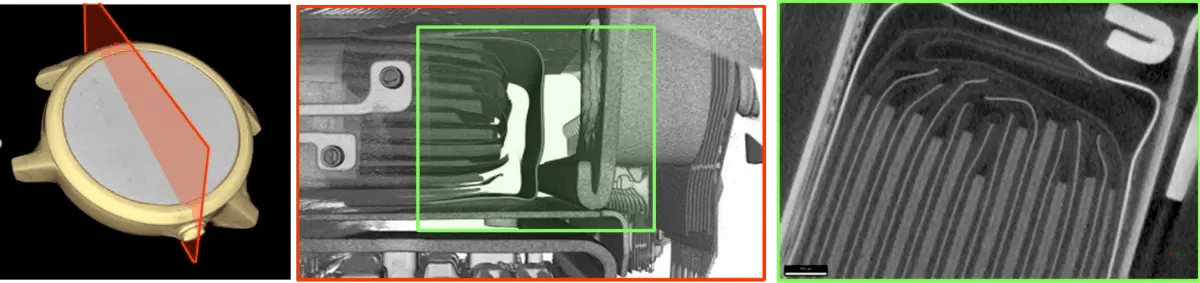

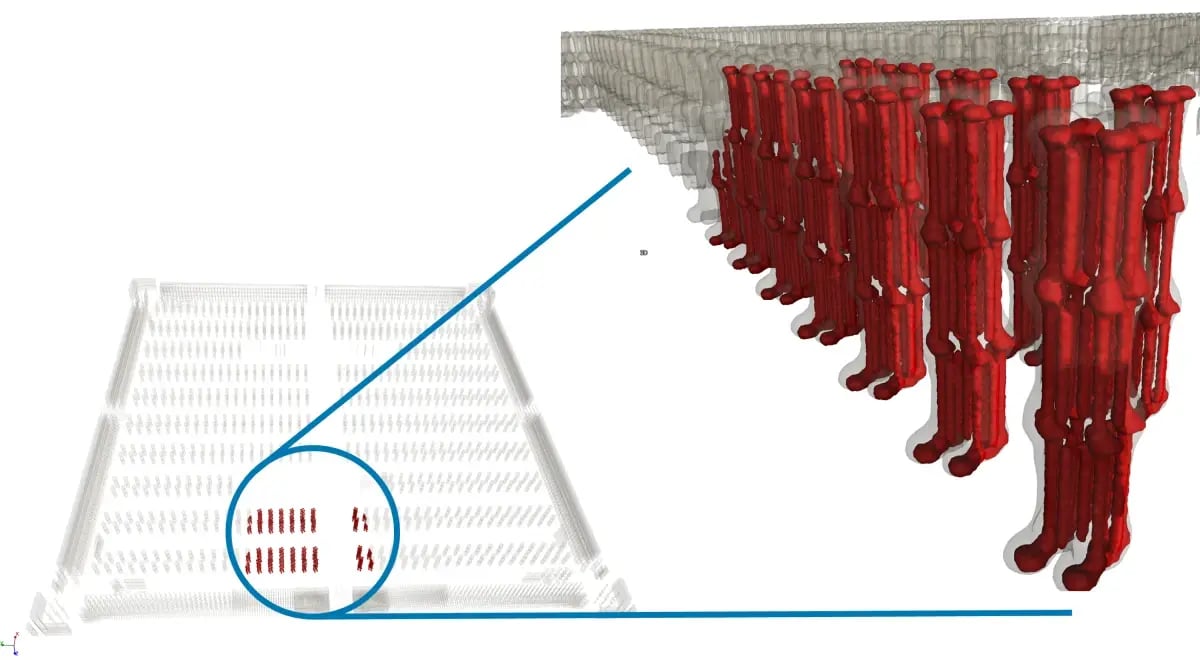

Tescan UniTOM HR provides submicron resolution and dynamic CT for small samples. It supports both overview and VOI scans in a single workflow, making it ideal for detailed component inspection.

- High spatial resolution below 600 nm for fine structural detail

- True 4D dynamic CT with sub-5-second temporal resolution

- In-situ compatibility with powered devices, pressure setups, and rotational stages

- Fast overview and VOI scans in a single workflow