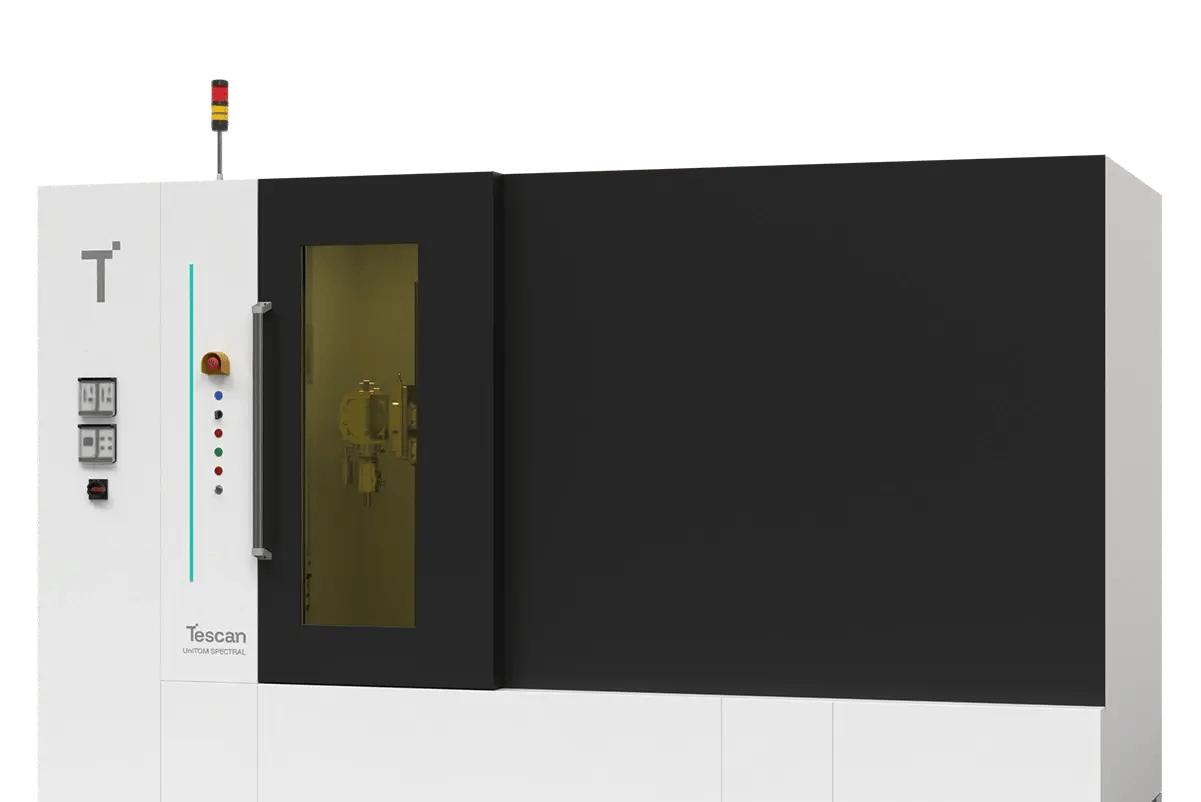

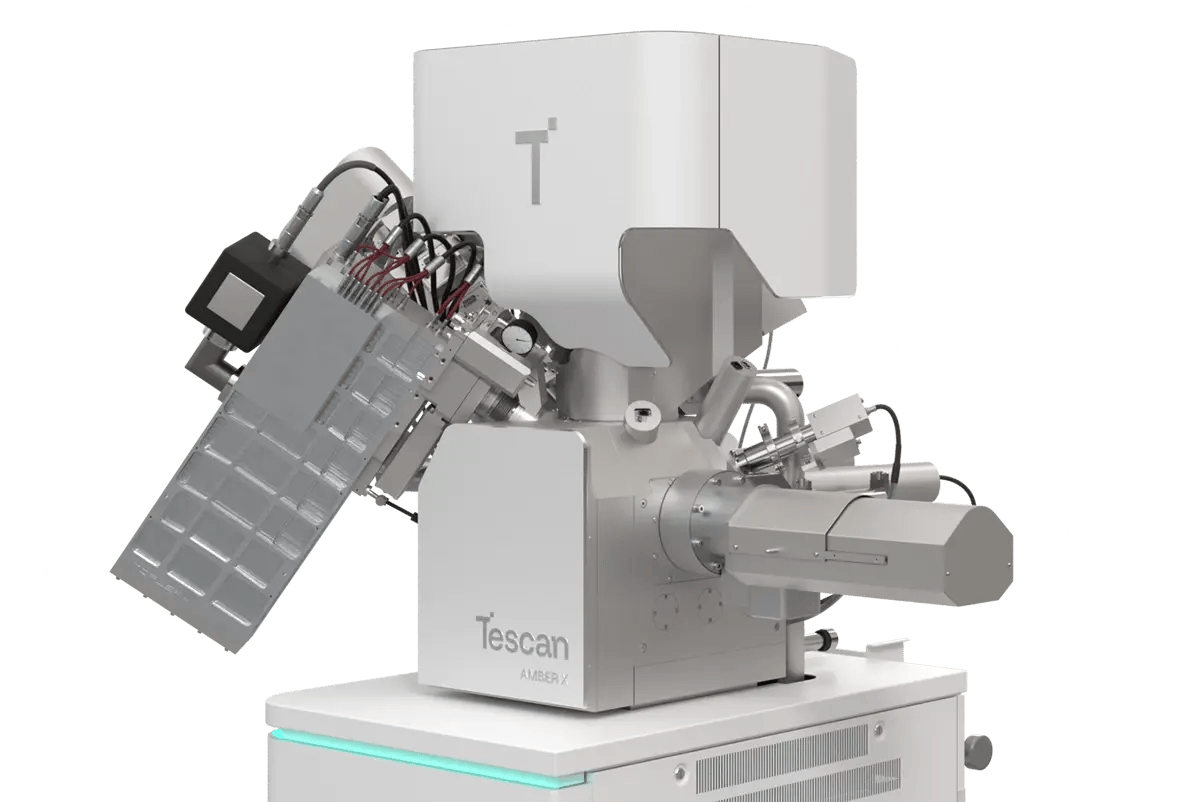

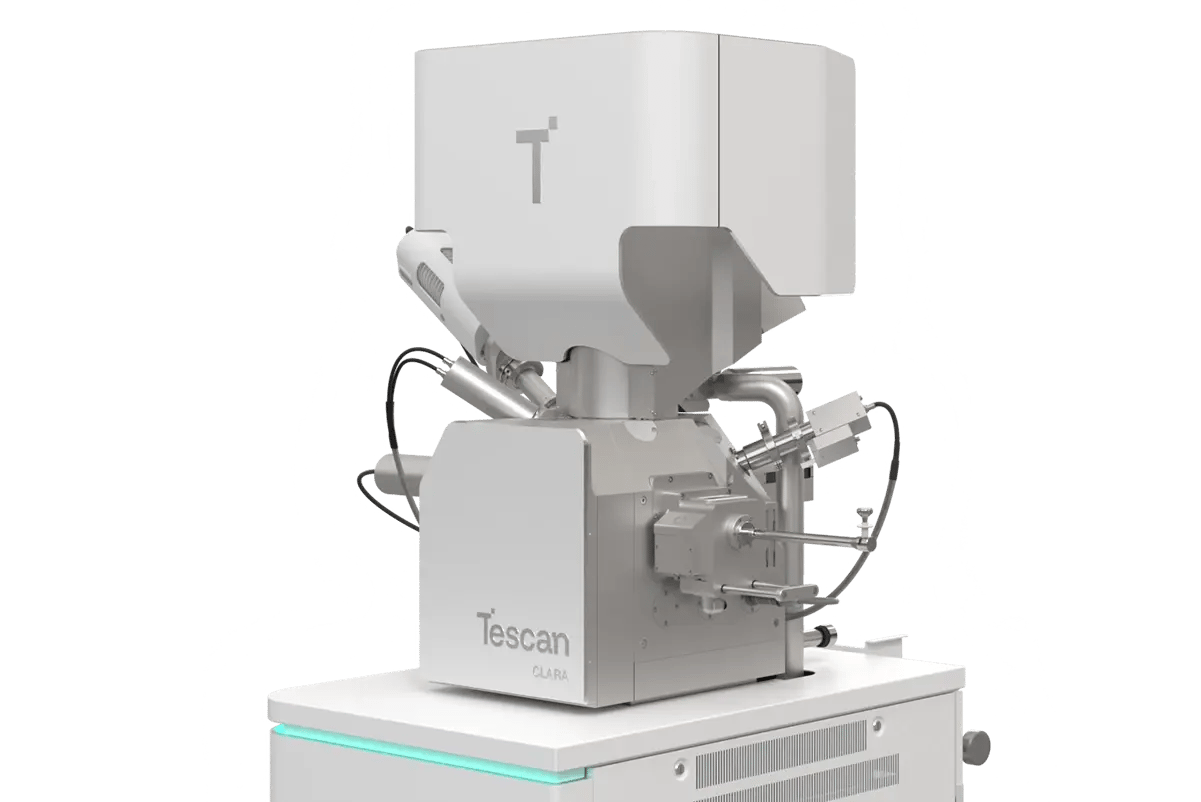

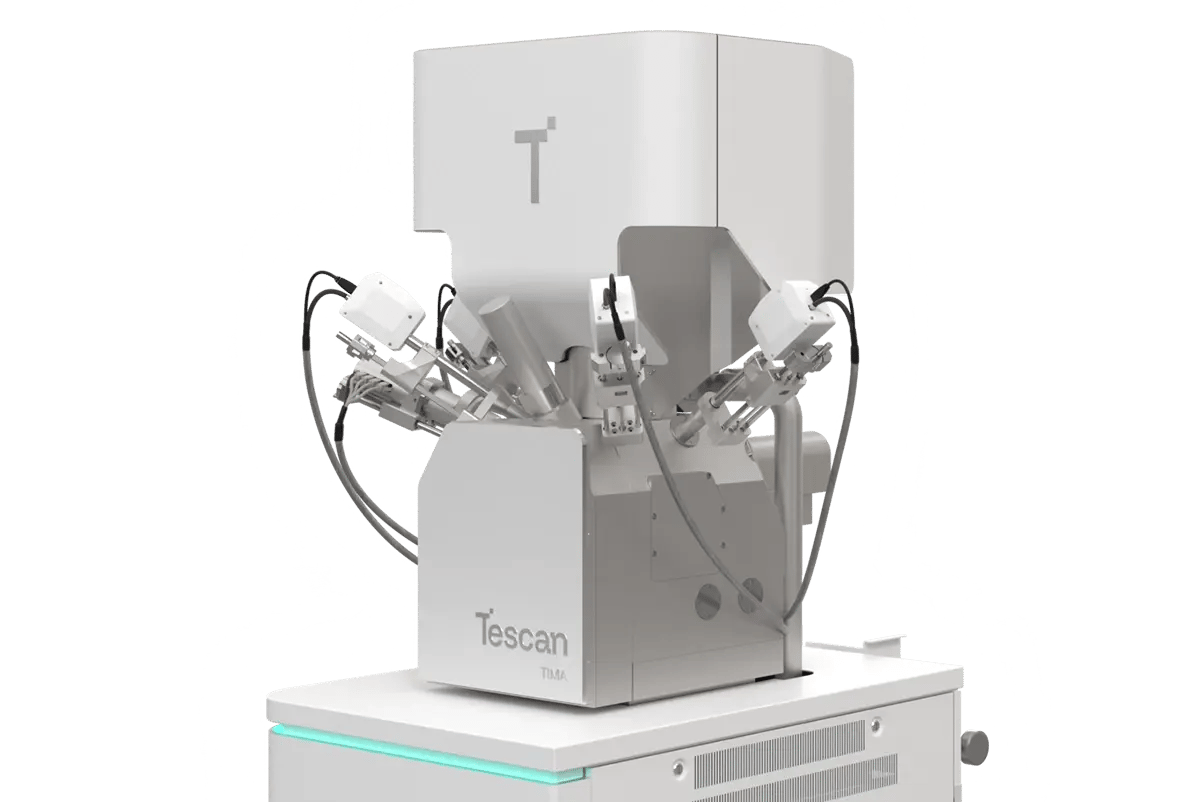

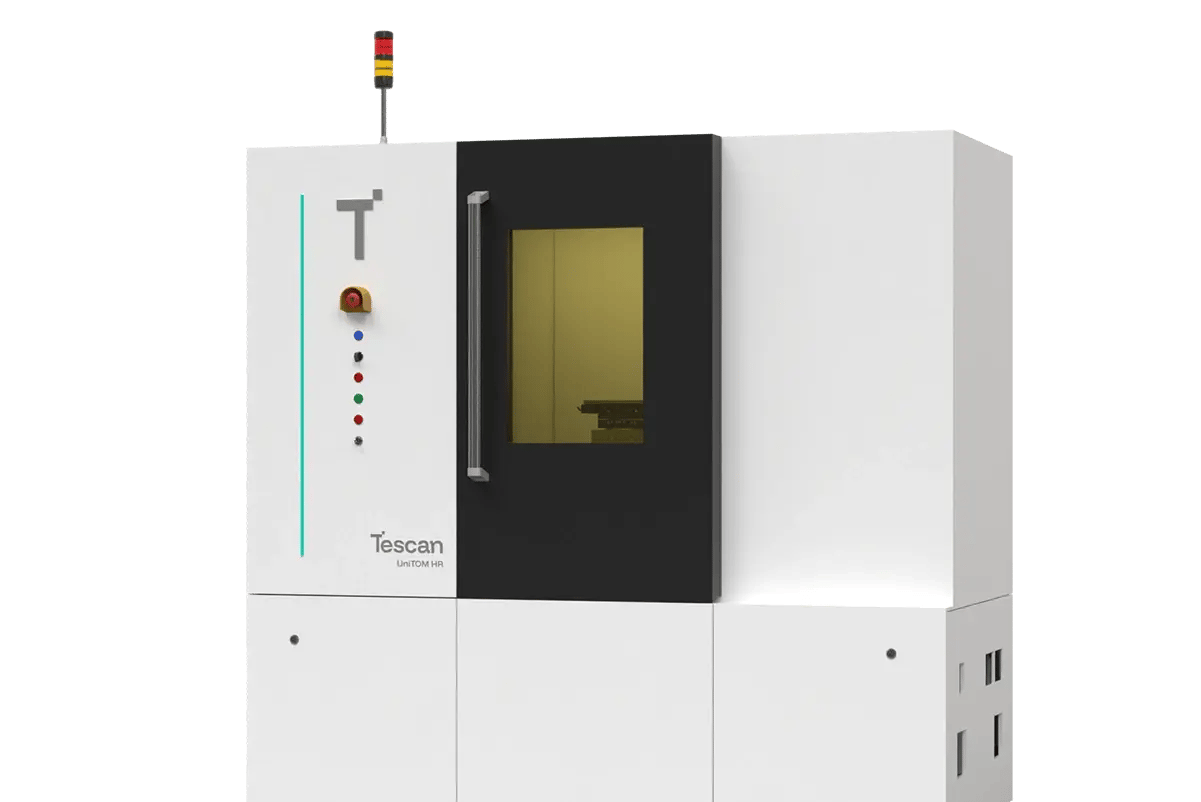

Achieve consistent quality in lithium-ion battery manufacturing while preserving sensitive cell structures. Tescan FIB-SEM and micro-CT workflows deliver reproducible 2D and 3D insights essential for battery quality assurance, covering electrodes, powders, separators, and full cells.

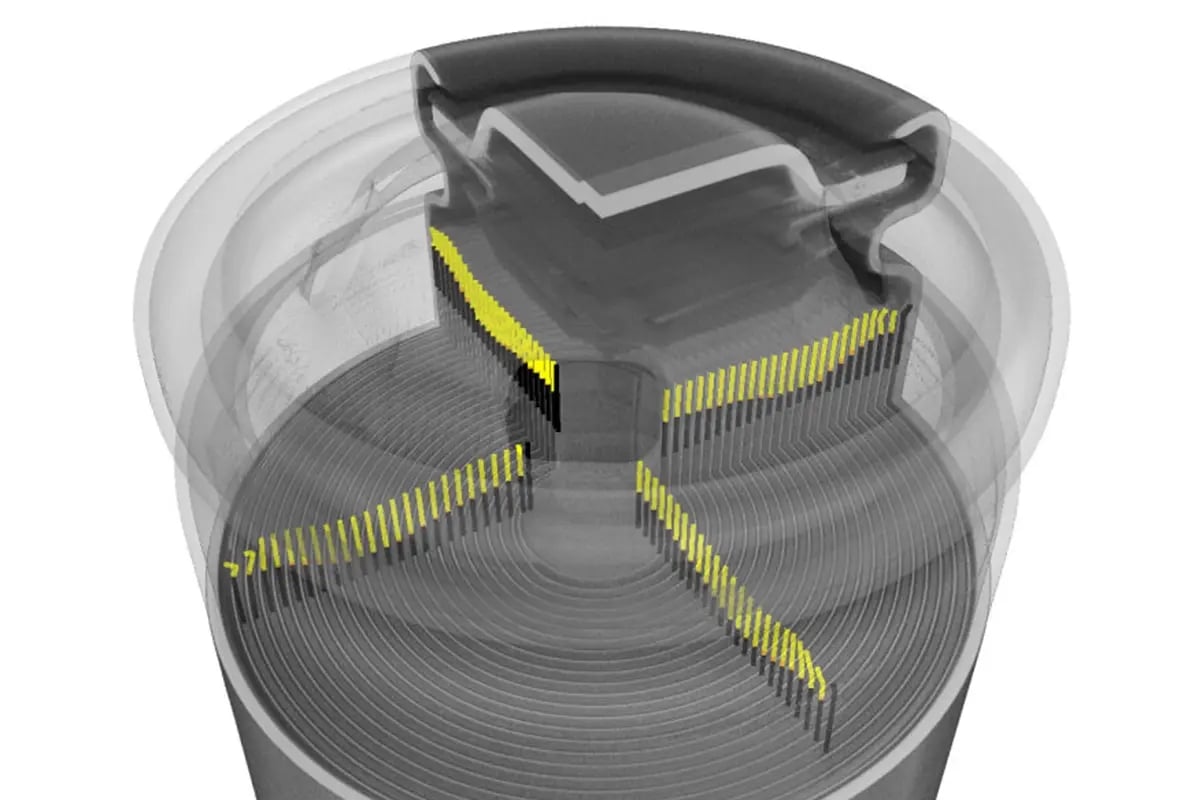

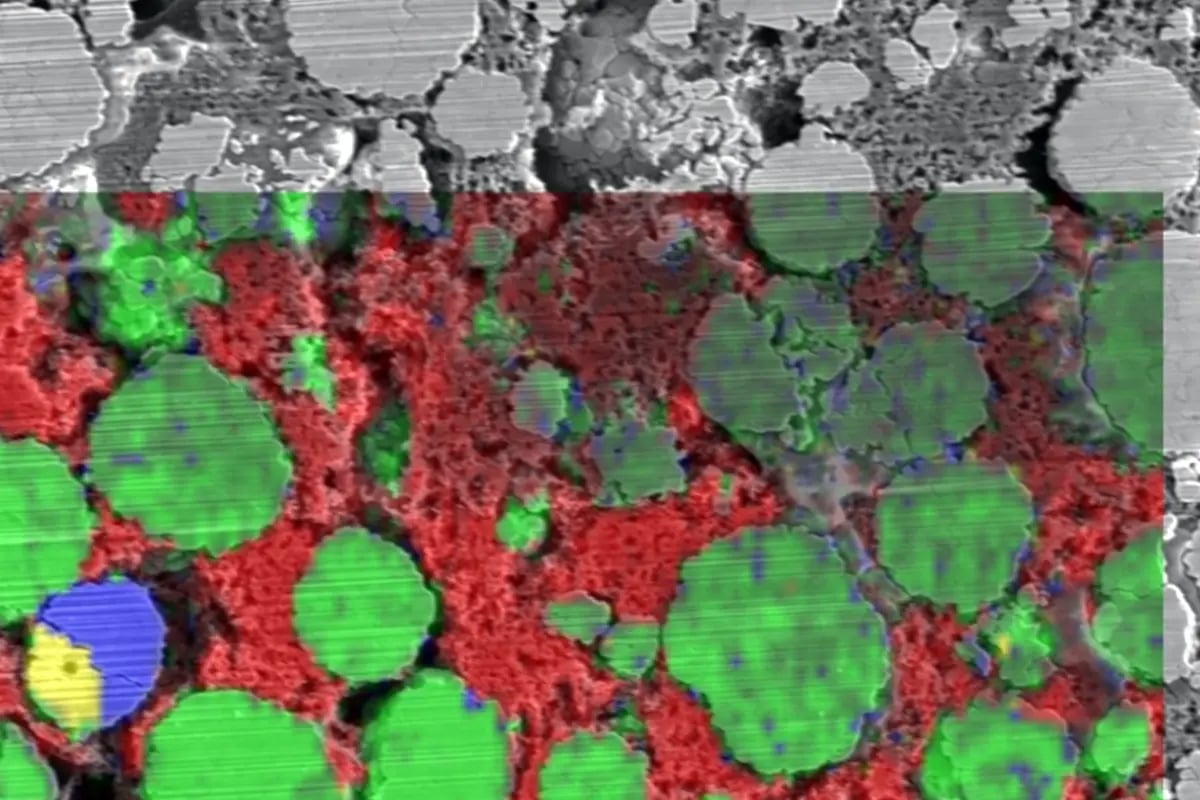

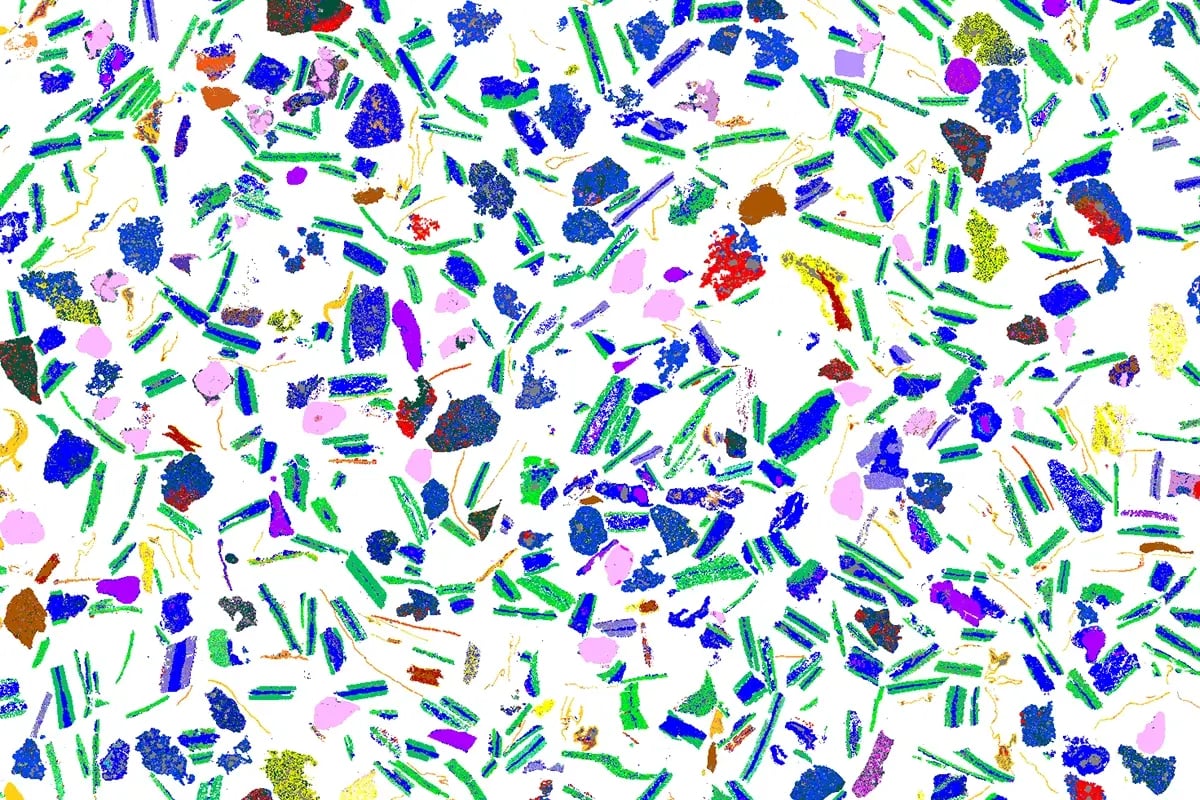

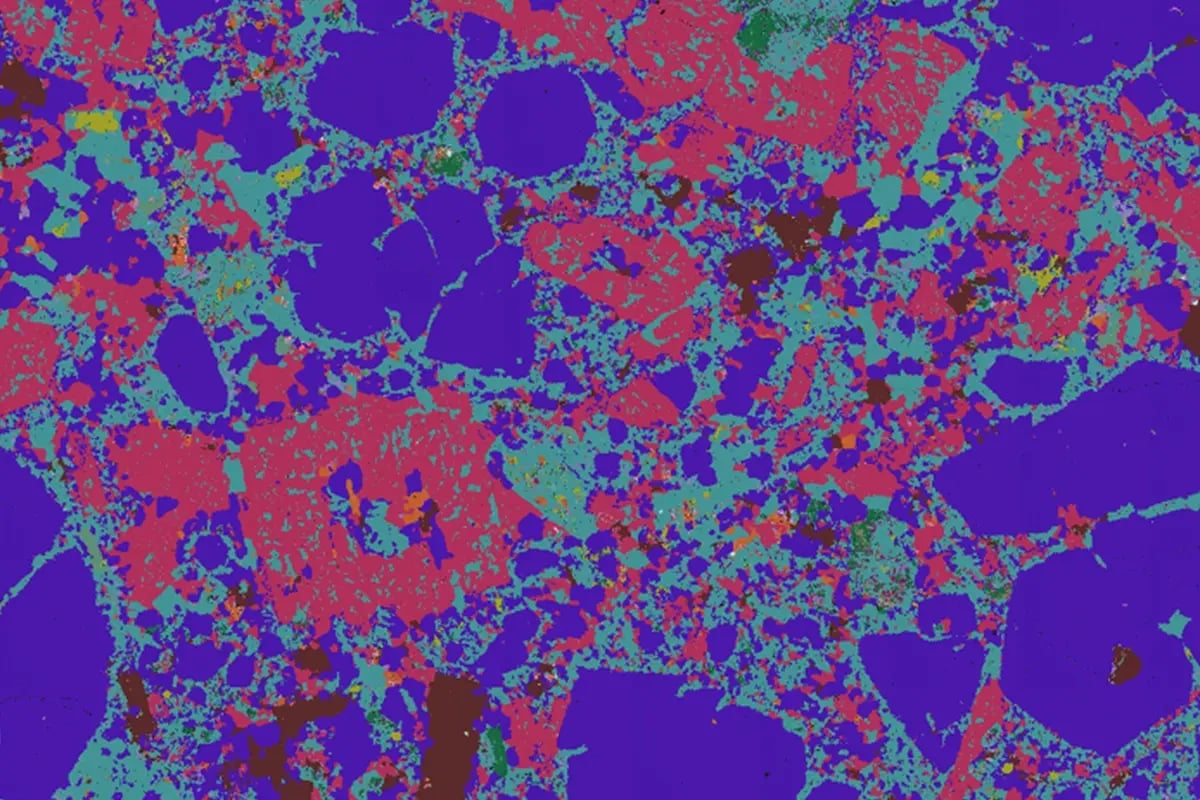

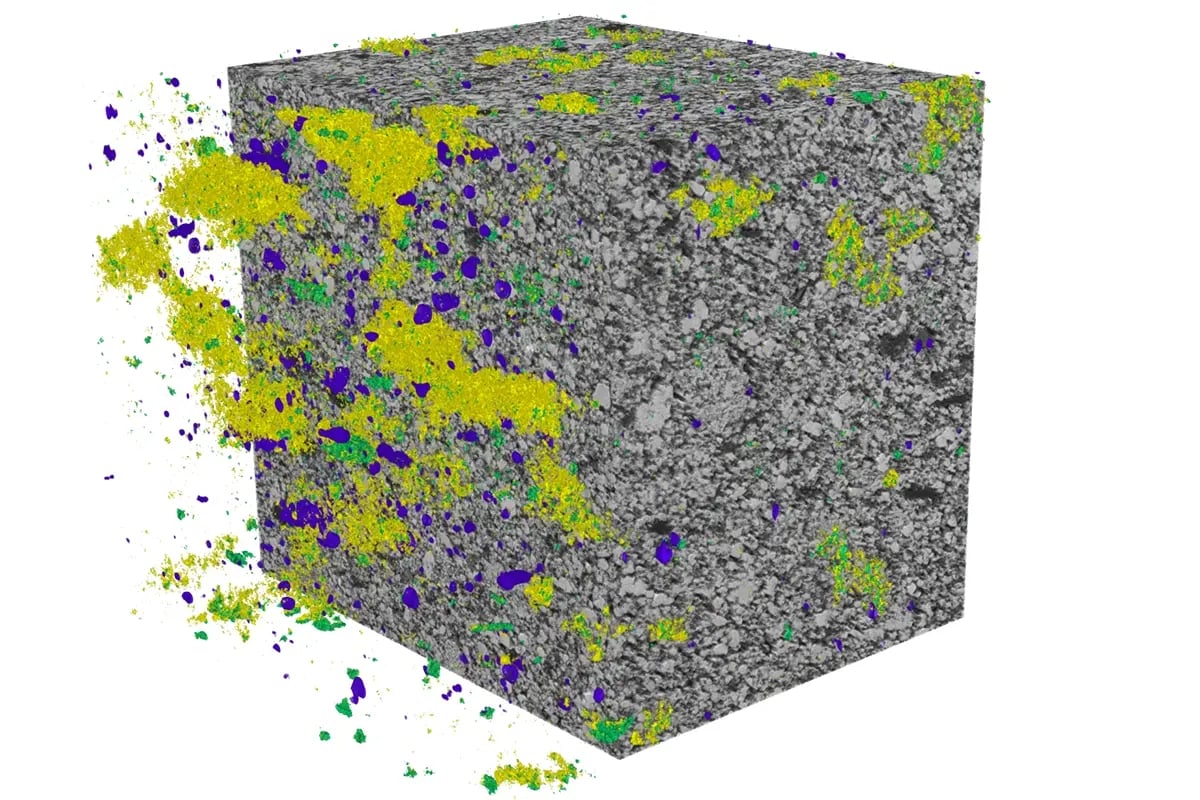

Tomography and automated SEM analysis highlight porosity, particle variation, and separator morphology, while non-destructive CT supports battery diagnostics by revealing electrode alignment and anode overhang in assembled cells.

Enable reliable results that improve yield, validate processes, and accelerate decision-making across the battery lifecycle.